Thanks to its continuous research and development effort and to the quality of its equipment, addressed to its maximum reliability, Gambarotta maintains a good position among the leading manufacturers of bucket elevators.

In this article, we would like to present one of the series of bucket elevators called ESPLV, which are included in the manufacturing program of Gambarotta Gschwendt.

They are double-chain bucket elevators that represent one of the most modern lines of heavy-duty elevators providing the highest flow rate: 2000 m3/h and higher. One of their main features is the large-sized buckets with a capacity of up to 290 liters each on the largest elevators. The chains are the mechanical type with pin and bush, also designed for very high breaking loads (up to 4000 kN).

Thanks to the continuous buckets, this series of bucket elevators have great flexibility allowing a wide range of speeds from low to high speeds. They are used when a low speed is required (less than 0.7 m/sec), as in the case of lifting granular fertilizer material or for lifting medium-sized materials (50-100 mm), and also when high speed is possible (> 1 m/sec) in order to minimize the size – and therefore the cost – of the bucket elevator required.

When speeds lower than 0.8-0.9 m/sec are required, the action of discharging the material, although external to the trajectory of the buckets, occurs due to the combined effect of centrifugal force and gravity, with the material flowing on the back of the preceding bucket, thanks to the continuous bucket system. Therefore, when the material is being discharged, the back of each bucket acts “as a slide” for that part of the material that is forced to follow a less effective expulsion trajectory due to insufficient centrifugal force. This allows an easy discharge through the outlet chute.

When lifting granular fertilizer, the low speed aims to minimize the crushing of the granules and the level of powdering, mandatory action to guarantee good product quality.

The low speed also allows the buckets to load (partly with dredging) and lift materials with larger grain size (80-120 mm)

- When speeds exceeding 1 m/sec are permitted (the most frequent case) – usually up to 1.5-1.6 m/sec – it is allowed the highest flow rate of material to be lifted. In this case, the material is usually discharged centrifugally.

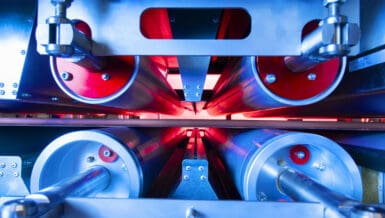

About one hundred elevators of this type have already been installed in these recent years. A hydraulic tensioning system is frequently used for tensioning the chains, thus allowing for high loads (if necessary) as well as easy and uniform adjustment of the chains. The larger bucket elevators are equipped with a double drive unit (see picture).

In the cement industry, this type of high-capacity bucket elevator is used to lift a wide range of bulk materials such as clinker, raw meal, raw mix, limestone, cement, coal, to name a few.

Recently Gambarotta acquired an order from Fives FCB for the supply of seven bucket elevators for a new 5000 Tpd cement production line in Qatar. In addition to the six, more traditional elevators with oval link chains, the ESPLV 1400 Raw mill outlet elevator stands out with its design flow rate of 1775 m3/h (bucket filling factor 90%) and nominal flow rate of 950 m3/h. This elevator is equipped with:

- double drive unit, each keyed on one end of the main shaft, consisting of a bevel-helical gear unit, a 132 kW electric motor, and a hydraulic coupling;

- two chains with a breaking strength of 1,500 kN each.

Another similar elevator was supplied a few years ago to the afore-mentioned FCB for Barroso Plant in Brazil.

An order for conveying and lifting machines was finalized recently with BUZZI UNICEM for the APZ2 Line of its Mexican subsidiary Cementos Moctezuma. This order includes two ESPLV bucket elevators for recycling material from the Horomill mills; one for the raw material and one for the fired material.

Since 1998, Buzzi Unicem company has selected ESPLV as recycling bucket elevators for the Horomill mills installed in its cement works.