Making the right choice together

Different mills have different mechanical effects; therefore, not all mills provide like results. Recently, neither Frewitt nor its customer knew beforehand which mill would provide the desired result; therefore, different mills were tested. This pharma customer was already familiar with previous applications using a competitor’s cone mill. The trial product was milled but resulted in a failure. The methodology required compatible process comparison. The customer decided to perform a series of tests on Frewitt’s cone mill, the FlexMill CW. Due to throughput requirements, it was determined the product would be milled on the FlexMill CW-150, with a sieve insert which, depending on the product properties, achieves a throughput of 500-1500 kg/h and grain sizes as small as 150 µm.

During previous trials involving products with similar properties, specialists at Frewitt surmised the limit would be reached with the FlexMill CW’s capacity. Acting on “better safe than sorry”, the product would also to be milled on a FlexMill OW-3, a sieve mill that switches between rotating and oscillating, providing low circumferential speeds, hence, suitable for gently milling temperature-sensitive products. Frewitt would also trial the FlexMill HW, a hammer mill with an extreme impact force, as it’s ideal for pulverizing free-flowing, hard products.

Laboratory trials bring clarity

At an ambient temperature of 22°C and 58% humidity, the free-flowing, hard product was tested on the FlexMill CW-150, FlexMill OW-3 and FlexMill HW-3 mills. In order to obtain the best possible analysis, the results were evaluated on a Mastersizer 3000.

During test series 1 and 2 and the subsequent tests on the FlexMill CW-150, Frewitt specialists strived to reach the targeted results.

Tests using a rasp with 1 mm openings brought unsatisfactory results, both at 800 rpm and 2000 rpm. While 10.8 kg of the 12 kg of product were milled in 3 minutes – 50 seconds at 2000 rpm, the temperature rose to 34ºC.

For test series 3 to 7, the rotor tooling was replaced, first by a rasp, and then by a special sieve with 0.5 mm openings, providing results similar to tests 1-2, except the temperature only reached 28ºC at lower speeds.

During each test, the product was too hard to pass through the sieve openings, ultimately heating up to 38ºC at higher speeds, therefore deemed unsuccessful. Further tests were required.

Thereafter, the FlexMill OW-3 was employed: During the eighth test, a 0.71 mm sieve and a circumferential speed of 1 m/s were used. For test 9, the FlexMill OW-3 was switched from rotating to oscillating, and product was ground and tests revealed similar results: From a 5 kg batch, 2.9 kg of milled product passed through the sieve during the oscillating movement, leading to blockages due to the lower speeds.

Another hypothesis suggested better results would be achieved with the FlexMill CW-150, despite earlier outcomes. Test 10 on the FlexMill CW-150 using another rotor arm and smaller sieve openings led to 2.4 kg of milled product out of a 5 kg batch passing through the sieve in 2 minutes and 20 seconds, also unsatisfactory.

Finally, the FlexMill HW-3, was used for tests 11 and 12. At a speed of 3500 rpm, during test 11, 5 kg of product passed through the Conidur sieve in 4 minutes-25 seconds and the product temperature did not exceed 29ºC.

During test 12, 25 kg passed through the same sieve at a throughput of 64 kg/h and a product temperature of below 29ºC. The goal was reached! Throughput reached, temperature respected and hence the product properties were protected in line with the customer’s specifications.

Final parameters to achieve perfection

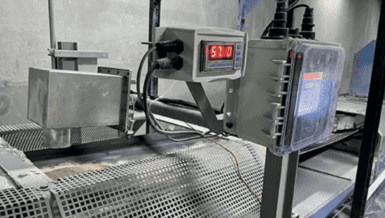

During tests, the FlexMill HW-3 was first fed a 5 kg batch, thereafter a 25 kg batch. At the customer, the mill was required to mill continuously. This requirement was met using Frewitt’s ProFi-Valve 80 dosing system, with a frequency converter and PLC. The system, having retractable WIP nozzles, is easy to rinse after the milling process and quickly ready for the next run.