This poses a significant risk to industries such as Food, Grain, and Feed. In response to this hazard, in 1945 the National Fire Protection Association (NFPA) initiated a tentative standard, NFPA 68 titled ‘Standard on Explosion Protection by Deflagration Venting’, updated in 2007 to a Standard, and is currently in its 2018 revision which provides specific direction to mitigate the risk through the use of venting. Today explosion venting is the most commonly used method of mitigating the pressure effects of a deflagration.

Designed to open rapidly at a predetermined burst pressure, explosion vents allow the combustion process to escape to the atmosphere while limiting the pressure generated inside the process equipment to calculated safe limits.

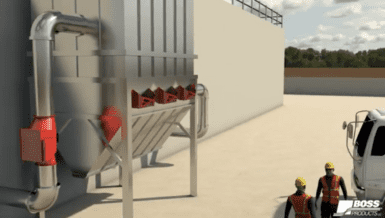

This type of vent is installed on dust collections, conveyors, bucket elevators, dryers/ovens, bins, and silos.

For more than 50 years, traditional composite vents comprised of plastic film sandwiched between two stainless steel sheets have been utilized for this purpose. However, this design approach has largely fallen out of favor in all but a few niche applications due to significant disadvantages, including the risk that dust and process debris can accumulate such that it affects the speed and reliability of the vent opening.

“Over time there can be an evolving risk with composite vents that leakage will occur, or that dust or process materials will accumulate within the layers and the vent will become very heavy and won’t function as it should,” says Geof Brazier, president of BS&B Pressure Safety Management, a manufacturer of a broad range of dust explosion prevention and protection technologies.

This has some facility personnel taking a closer look at more advanced single sheet vent alternatives that weigh less and include design features that make them more durable, even in the presence of light vacuum conditions or vibration. These modern options also reduce installation costs while increasing service longevity.

Vent Inspection

NFPA 68-2018 Standard on Explosion Protection by Deflagration Venting establishes requirements for the design, location, installation, maintenance, and use of devices and systems that vent the combustion gases and pressures resulting from a deflagration within an enclosure so that structural and mechanical damage is minimized.

Within the NFPA 68 Standard is the requirement that installed explosion vents in service “shall be inspected” to ensure their integrity as they perform a critical safety function.

However, in practice, many view explosion vents as ‘set it and forget it’ safety devices, and often fail to complete periodic inspections.

According to Brazier, regular “up-close-and-personal” inspection is critical given that internal damage and material accumulation is typically not visible at a distance.

In many cases, this set-it-and-forget-it approach is owing to a less-than-complete understanding of the risk factors associated with composite vents compared to more modern alternatives.

Composite Vents

The composite vent design was introduced by BS&B Safety Systems for more than 50 years and marked a milestone in the achievement of low set pressure from relatively thick sheet metal.

Composite vents are typically made of a 3-part sandwich construction of plastic film seal between two sheets of metal, usually stainless steel. The two metal sections are slotted with intermittent uncut sections that control the burst pressure and vent opening.

The outlet side metal section controls burst pressure, while the inlet metal section protects the fragile plastic film and provides some degree of vacuum resistance. In this design, the vents “open” typically at 1 to 1.5 PSI set pressure.

Composite vents can be either flat or domed, depending upon the application conditions, with domed vents being recommended for vacuum service.

The disadvantage of this type of construction is that it allows dust to penetrate between the inlet side sheet metal and plastic film, resulting in leakage overtime when angular dust particles puncture the seal.

Although significant damage to explosion vents may be visible at a distance, internal damage may not be observable without close inspection.

If damaged, the vent could draw in humid air and even rainwater, particularly under light vacuum pressure. This can potentially affect the product inside process equipment. For dry items in storage, for example, moisture can cause clumping of material and even the agglomeration of dusty material.

“It can be a real inconvenience if the customer’s process is impacted because an explosion vent is damaged,” says Brazier.

There are additional risks associated with sandwich-style composite vents.

Over time, pounds of debris can accumulate inside the layers, doubling and even tripling the weight. In cold weather conditions, icing can occur as well.

“We’ve seen instances where a small 3-foot by 3-foot vent that weighs 20 pounds brand new, after years of accumulating material between its layers, now weighs 40 pounds.”

In addition to being unsanitary, particularly for food processors, the increase in mass due to the accumulation of material means that the vent will not open as fast as planned. The result can be higher-than-expected pressure in the dust collector or other protected equipment in the event of explosion vent activation. “Without the expected relief [from venting] a dust explosion can overpressurize the equipment, causing significant damage,” says Brazier. “Worst case, the explosion could escape through a weak point – and not the explosion vent – causing an uncontrolled release of flame, dust, and pressure where it wasn’t planned.”

Single Section Vents

As the demand for explosion protection technology grew, BS&B later developed the single section vent. In this design, a single sheet of metal is intermittently cut about its perimeter and then gaskets are applied to cover the cut pattern.

Eliminating the fragile plastic film seal and one sheet of metal greatly reduces the mass of an explosion vent, making it more efficient at responding to the rapid rate of pressure rise arising from a dust or gas explosion.

The superior design allows the vent to handle high vacuum operating conditions and cyclical operating pressure conditions. It also eliminates product build-up, enabling the vents to be used in clean service applications.

Single Section Compound Domes

In 2010, BS&B improved on the single section vent design by altering the shape of the dome to a unique compound geometry. This advance was born out of a desire to increase the vacuum resistance of the vents, without increasing the weight.

The compound dome has curves at the corners of rectangular and square vents that deliver even greater rigidity for high vacuum or vibration applications.

The primary purpose of the domed construction, on the other hand, is to provide greater intrinsic vacuum resistance. This is important, as storage, pneumatic conveying, and dust collection systems often operate under light vacuum conditions. Industrial dust collectors can also utilize short pulses of compressed air to clean and extend the life of their bag or cartridge filters.

In these types of operating conditions, domed vents are more stable and resilient, increasing service life when compared to flat alternatives.

According to Brazier, the vent mass is critical when calculating vent sizing. Recent revisions of NFPA 68 include a review of vent mass for every application. The results may mandate a larger vent area for less efficient, heavier explosion vents.

In short, this means a composite vent would require a much larger vent area to perform the same job than more efficient, lightweight, and modern alternatives. This adds to the costs of installation.

“Everything we can do to keep vents lightweight, vacuum resistant, vibration resistant, and ultimately very stable helps us avoid increasing the vent area,” says Brazier. “This means a more economic installation for the customer.”

Brazier adds that these factors have increasingly come into play in the past ten years, creating the very real possibility that aging explosion vents may be sized and selected without allowance for the mass or inertia adjustment factors.

The compound dome feature has also resolved another longstanding challenge involving the framing on which the vents are mounted.

In many cases, these frames are built by the end-users out of angle-iron. Over time, the framework can bend or buckle – a common occurrence that can reduce vacuum resistance and can even cause the vent to fail.

The improved compound dome design is more tolerant of variations in the framing and less sensitive to the operating application and installation conditions.

For its flagship VSM product, the company has also included an integral frame to the vent flange to further simplify installation.

“These design features provide more control over how the vent behaves in the field and much less relevance to what happens on the user side [installation],” says Brazier.

Applications for Composite Vents

While single piece vents offer the best solution for most applications, there are some exceptions where composite vent technology provides the best performance. In particular, this is for applications that utilize combustion systems with hot exhaust gases.

The BS&B patented HTV vent has internal thermal insulation that allows for service conditions in excess of 1000 degrees Fahrenheit.

With this type of vent, insulation material isolates the plastic film and burst control metal section from extremes of service temperature.

“By placing the insulation inside the layers of the composite vent, you can achieve very high resistance to temperature while maintaining the low set pressure explosion protection capabilities,” says Brazier.