From epoxies to sealants, adhesives to paints, we have the solution for your needs.

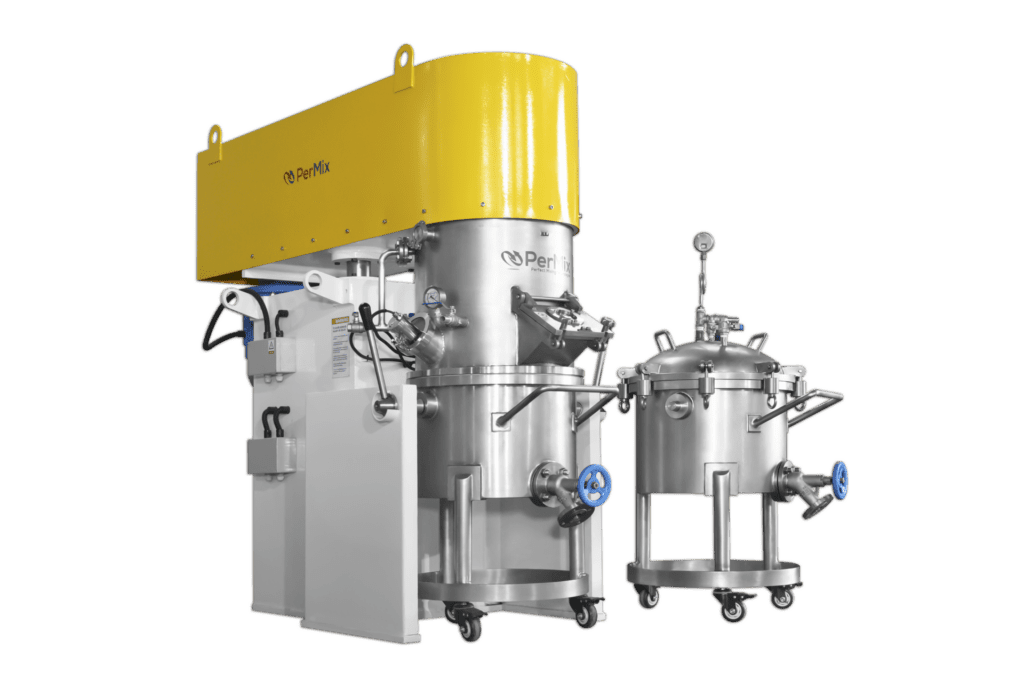

PerMix has special designs of the Double Planetary Mixers according to the special requirements and applications of the customer.

Some modifications include:

- For mixed products that must be heated or cooled, PerMix has designed jacketed vessels for hot oil, electrical heating, steam heating and liquid cooling.

- PerMix has designed moveable and tilt-able mixing vessels, with or without a bottom discharge valve for less viscous liquids and units with a special no dead area valve for connection to peripheral equipment. Arrangements can be made for the transport of the vessel by forklift or by crane.

- Where necessary, alterations can be made in the shape of the mixing tools; a third mixing tool may be added; a homogenizer unit (with deflector) can be supplied – and other performance proven mixing elements may be supplied for special duties.

- A PerMix DISSOLVER UNIT for fine dispersion, with its own drive unit, available with or without variable speed, has proven itself a good process accelerator for dealing with special dispersions.

Come see the PerMix difference