This leads to higher costs, longer development times, and an increased risk of process deviations. However, this problem is poised to be solved with the arrival of a new and innovative technology: Cognitive Pharma Machinery.

The technology is the result of a partnership between Luperini, a company experienced in machinery design and manufacturing, and Eigengran, an expert in developing advanced control systems using IIoT sensors and AI algorithms. The combination of these two fields of expertise results in a unique and practical solution to the challenges faced by the pharmaceutical industry. At the heart of this technology are self-learning neural networks (Deep Reinforcement Learning) that analyze and interpret data in real-time. These algorithms build predictive control models, allowing the machinery to continuously improve its control strategies and adapt to changing conditions, reducing the risk of process deviations.

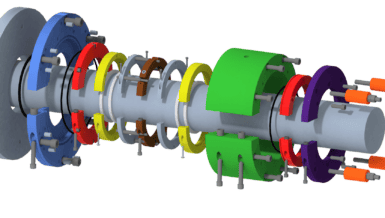

The use of Cognitive Pharma Machinery in high shear wet granulation (HSWG) and powder blending, two critical processes in the manufacture of oral solid dose pharmaceutical products, offers several technical innovations that can improve the quality and safety of these products. The use of IIoT sensors and AI algorithms in the design stage of the machinery means that it is born to perform autonomously and continuously improve its performance. This represents a major improvement over traditional machinery and control systems, which rely on pre-defined rules and a limited amount of data, leading to manual adjustments and an increased risk of operator error.

The implementation of Cognitive Pharma Machinery in the HSWG and powder blending processes can lead to increased efficiency and productivity. The machinery’s ability to self-optimize means it can find the optimal operating conditions, reducing the time and effort required to make process adjustments. The technology also complies with the Process Analytical Technology (PAT) guidelines, making it a practical embodiment of Pharma 4.0, the fourth industrial revolution in the pharmaceutical industry. This is an important step towards achieving Quality by Design (QbD) in the pharmaceutical manufacturing process.

In conclusion, Cognitive Pharma Machinery is a game-changer in the pharmaceutical industry. The ability to embed IIoT sensors and AI algorithms in the machinery at the design stage results in equipment born to perform autonomously, continuously improving its performance, and solving the long-standing problem of process scale-up. This new technology is poised to revolutionize the way pharmaceutical products are manufactured, making it a must-watch for companies looking to stay ahead of the curve in the rapidly evolving field of Pharma 4.0.