Common process equipment including spray dryers, fluid beds, cyclones, dust collectors, blenders, milling equipment, and storage vessels can accumulate or generate combustible dust or vapors. When these particulates are suspended in air, all that’s needed is an ignition source to trigger an explosion.

Primary and Secondary Explosion Risks

The danger isn’t confined to the initial equipment. A primary explosion within one vessel can generate a pressure wave and flames that escape into surrounding areas. This can lead to secondary explosions—often more destructive than the first—damaging buildings and endangering lives. Flames and pressure can also travel through ducts, conveyors, and other interconnections, spreading the risk across the facility.

Safeguards to Minimize Explosion Risk

1. Dust Hazard Assessment & Ignition Control

The foundational step in understanding the explosion risk is performing a Dust Hazard Analysis (DHA). This assessment will often help define potential ignition risks within the process. Facilities then must implement ignition controls such as static grounding, bonding, and spark detection systems. While crucial, these controls alone do not offer complete protection. There are a number of different methods available to protect vessels against explosions, these can include:

2. Explosion Relief Venting

Explosion vents are designed with a rupturable membrane that opens under overpressure. This safely directs the explosion’s force to a designated safe area, preventing the explosion overpressure from exceeding the structural limits of the vessel.

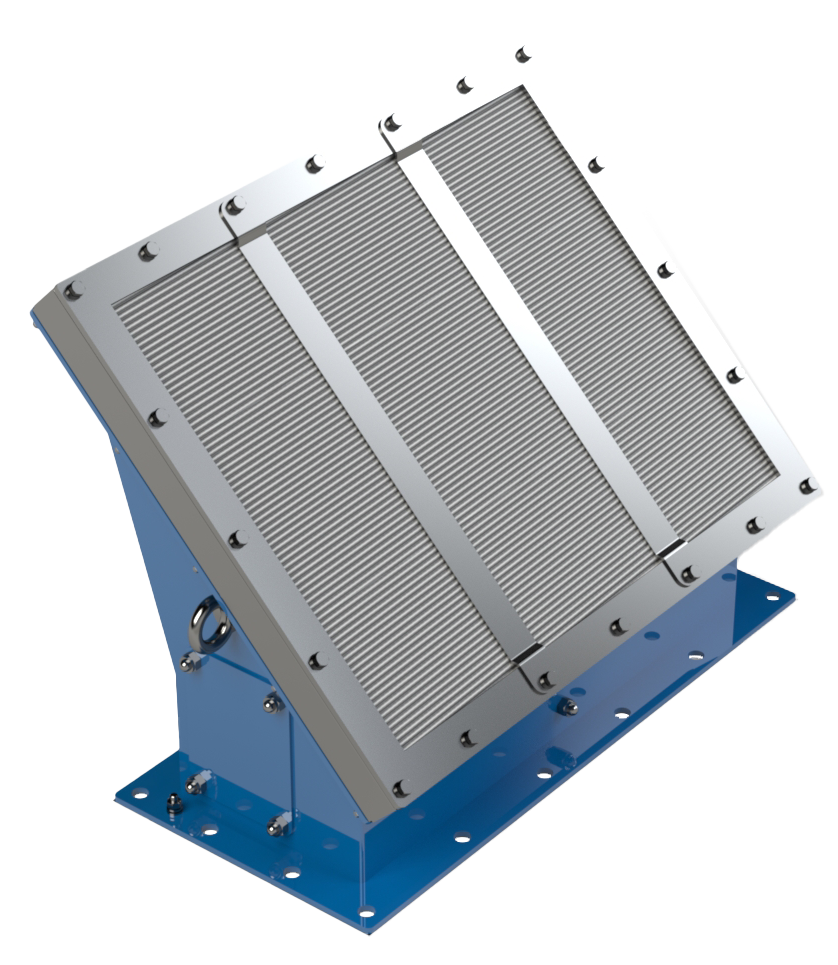

3. Flameless Venting

Ideal for indoor equipment, flameless vents combine a relief vent with a flame arrestor, such as a mesh trap. These devices safely release pressure while containing flames and particulate, preventing fire from entering the workspace.

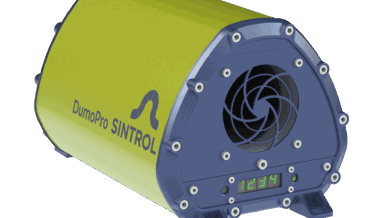

4. Explosion Suppression Systems

Where venting isn’t feasible, explosion suppression systems are used. These systems detect the early stages of a deflagration and within milliseconds, deploy a chemical extinguishing agent. The rapid dispersion of the extinguishing agent arrests the fireball before damaging overpressure develops. Advantages: No external flame discharge and reduced risk of post-deflagration fire.

5. Explosion Isolation Devices

To prevent explosions from spreading between equipment through interconnections, active or passive isolation devices are critical.

· Active Isolation: Uses detectors and a control system to deploy suppression chemicals or high-speed gate valves into ducts.

- Chemical isolation injects agents (e.g., sodium bicarbonate) to chemically inhibit flame propagation.

- Mechanical isolation closes the duct via a fast-acting valve.

· Passive Isolation: Devices such as flap valves actuate from explosion pressure and airflow. These require no power or detectors and are commonly used on dust collectors.

Summary

Dust explosions in food processing facilities are preventable. By identifying where explosive atmospheres may form, controlling ignition sources, and implementing explosion protection strategies—including venting, suppression, and isolation—facilities can significantly reduce the likelihood of a catastrophic incident.