Dynamic weighing is essential in many industrial processes that involve managing a continuous variable weight. An example is weighing a product on a conveyor belt. At the point of weighing, the material could be on the weighed section of the belt for only a couple of seconds. Dynamic weighing equipment can be divided into three main categories. These are:

- Discontinuous weighing systems

- Discontinuous totalizing weighers

- In-motion weighing systems

Discontinuous weighing systems

An example of weighing equipment of this type is the process batch weighing systems. These systems range from single weigh vessel systems where each ingredient is weighed sequentially and layered into the weigh hopper to complex weighing systems where ingredients are weighed simultaneously.

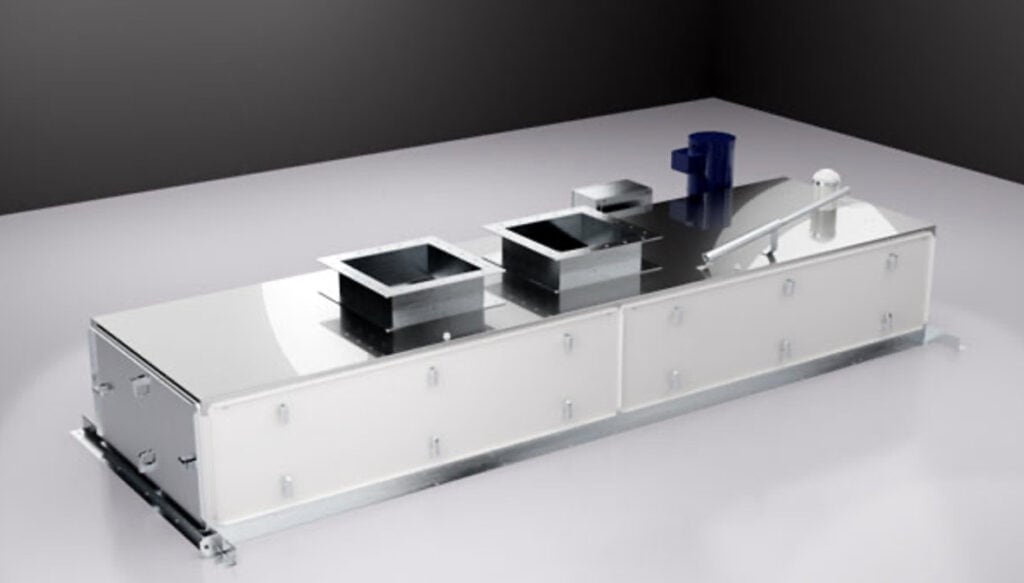

Discontinuous totalizing weighers

The equipment used in grain or rice milling is called the in-process weighers. Their primary use is to determine both the short and long-term cumulative weights of a product stream.

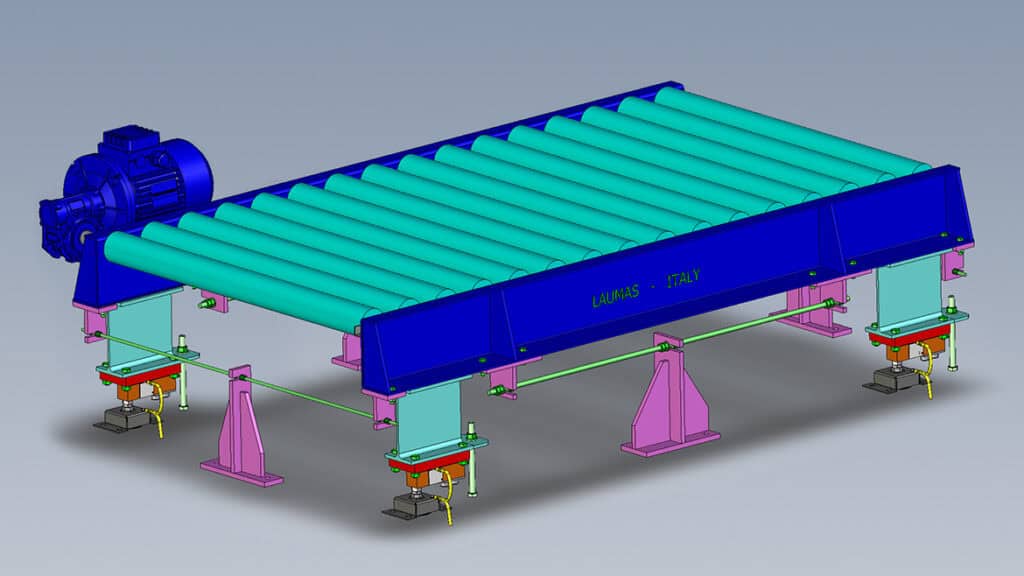

In-motion weighing systems

The belt and feeder weighers are part of this category. Conveyor belt systems are used to transport a wide range of powders and granular materials continuously. These kinds of equipment are most commonly used in agricultural, mining, pharmaceutical, and food processing industries.