This case study describes an incident at a mid-sized UK cereal processing plant, where inadequate control of oat flour dust and poor maintenance practices led to a flash fire and could have led to a subsequent secondary explosion. The event resulted in no serious injuries but did cause equipment damage and a production outage.

Root cause analysis revealed lapses in hazard identification, poor maintenance of dust extraction systems and equipment and a culture that prioritised output over preventive maintenance. The case highlights the importance of effective Process Safety Management, regular inspection of dust control systems, adherence to DSEAR/ATEX requirements, and strong safety leadership to manage combustible dust atmospheres.

Introduction

Combustible dust explosions are a recognised hazard in industries handling fine particulate solids, including food processing, woodworking, and chemical manufacturing. Despite well-documented incidents such as the 2008 Imperial Sugar refinery explosion in the United States (14 deaths and 36 injured), many facilities underestimate the risk posed by seemingly benign materials like flour, sugar, or grain dust. In the UK, these hazards fall, among others, under the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR).

This case study examines an incident and focuses on the technical, organisational, and cultural factors that contributed to a serious combustible dust event.

Case Description

Background

The company operates a cereal processing and packaging facility in the UK, producing rolled oats and oat flour for the UK retail market. The site has four milling lines, each with hammer mills, pneumatic conveying systems, and cyclone separators. A central baghouse dust collector services multiple process streams.

The facility had last undergone a DSEAR assessment five years prior. While combustible dust hazards were identified, no major incidents had been recorded, and dust accumulation was generally considered “under control.”

Incident Sequence

On a Tuesday morning in March, operators on Line 3 noticed intermittent surges in the pneumatic conveying system. Unknown to them, the reverse pulse filter cleaning system was partially blocked leading to reduced airflow that allowed fine oat flour to settle inside ducting.

At 10:42 a.m., a spark from a misaligned metal component in the hammer mill ignited the suspended dust cloud within the mill housing. The resulting primary flash fire was largely contained within the equipment, but the overpressure caused dust to be dislodged from overhead beams in the surrounding area. This could have created a secondary dust cloud that, if ignited, could have led to an explosion, potential fatalities and greater equipment damage. Fire alarms triggered automatically, and the site emergency plan was enacted. All lines were shut-down pending the companies investigation.

Investigation and Findings

A root cause analysis identified the following contributing factors:

- Mechanical Failure – The hammer mill had not been inspected for over 18 months. The worn rotor created a partial blockage. The reverse pulse filter cleaning system had been inspected, but the documentation confirming this was missing.

- Dust Accumulation – Housekeeping audits were irregular. Significant deposits of fine dust were found on horizontal surfaces and in poorly ventilated areas.

- Ignition Source – The hammer mill’s internal wear plates were overdue for replacement. Metal-to-metal contact produced sparks.

- Deficient DSEAR Compliance – The last hazardous area classification and risk assessment was five years old and did not account for changes in production volume.

- Organisational Culture – Operators reported a culture of “fix it when it breaks” rather than preventive maintenance. Production demands were prioritised over scheduled shutdowns.

Discussion

This incident illustrates several well-established principles in combustible dust safety management:

- The Primary–Secondary Explosion Phenomenon – The first event may be small, but it can disturb settled dust, creating a larger, more destructive secondary explosion.

- Importance of Equipment Integrity – Components such as explosion isolation valves are critical in preventing flame propagation between process units.

- Preventive Maintenance and Inspection – Mechanical wear is a predictable hazard. A robust inspection programme is essential to detect and address early signs of failure.

- Housekeeping as Process Safety – Dust accumulation is not just a hygiene issue; it is a major hazard control measure under DSEAR.

- Dynamic Hazard Assessment – Hazard assessments must be updated when processes, production rates, or materials change.

- Safety Culture – Leadership commitment is essential to ensure that safety-critical maintenance is not deferred for production targets.

Outcome

The incident resulted in:

- >£1.2 million in equipment damage.

- Regulatory enforcement notices under DSEAR and the Health and Safety at Work etc. Act 1974.

- A requirement for the company to implement a Process Safety Management framework including:

- DSEAR reviews.

- Formal preventive maintenance schedules

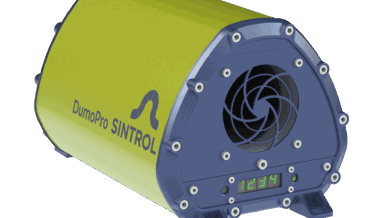

- Installation of explosion isolation valves.

- Improved housekeeping regimes.

- Enhanced safety leadership training.

Learning Points

- Combustible dust hazards are real and significant, even with food-grade materials.

- Primary explosions can trigger more dangerous secondary explosions through disturbed settled dust.

- Critical equipment must be maintained in full working order to prevent ignition and flame propagation.

- Housekeeping is a process safety control, not just a cleanliness measure.

- Hazard assessments must be kept current and reflect actual operating conditions.

- Strong safety culture is essential — preventive maintenance must not be compromised by production pressures.

Conclusion

The case underscores the potentially severe consequences of inadequate combustible dust management. Effective Process Safety Management requires not only technical controls such as dust collection systems and explosion isolation devices, but also a robust organisational commitment to hazard identification, preventive maintenance, and continuous improvement.

Even in industries handling food products, the hazard potential of combustible dust is significant and demands the same level of rigour applied in chemical manufacturing. Facilities that treat dust control as a priority — rather than a housekeeping issue — are far more likely to prevent catastrophic incidents.