But efficiency brings risk. Many common substances – from dusts and powders to vapours released during processing – can create highly flammable or explosive atmospheres. Without the right precautions, a single spark or poorly sealed enclosure could trigger a serious incident.

That’s why, under the UK’s Dangerous Substances and Explosive Atmospheres Regulations (DSEAR), businesses are required to classify their hazardous process areas into zones and ensure that only properly certified equipment is used. Getting this right means protecting people, property, and reputation.

Understanding Area Classification

Area classification refers to the process of assessing how likely it is that an explosive atmosphere will form during operations. Zones are defined according to the type of substance (dusts or gases) and the frequency and duration of the hazard. For dusts, this means Zones 20, 21, or 22; for gases and vapours, Zones 0, 1, or 2.

In practice, potentially hazardous atmospheres arise more often than many operators realise:

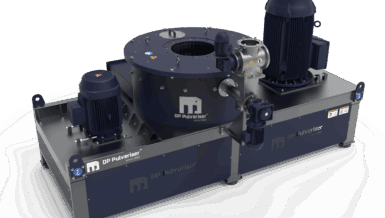

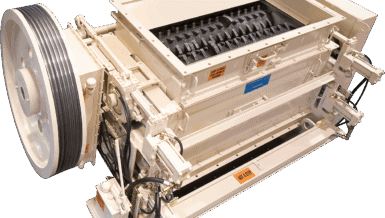

- Shredding plastics can create fine dust.

- Milling powders can create dust clouds capable of igniting.

- Briquetting biomass can release residual volatile gases.

Each of these presents a real risk if left unclassified or unmanaged. By correctly defining zones, businesses can set a clear foundation for safety: knowing where hazards exist, which substances are involved, and how likely those hazards are to occur.

Getting this step wrong can expose staff, assets, and the environment to unacceptable risk. More importantly, it undermines later decisions around what equipment to use and how it should be installed. Correct zone classification is the essential first step before selecting or installing any shredder, crusher, mill, compactor, or briquetting system.

Why Certification Matters

Once zones are classified, the next step is to ensure that equipment is appropriate for the environment. Under ATEX and DSEAR, this means using equipment certified to operate safely in the designated zone.

Certification ensures that equipment is designed and built to prevent ignition. This can include:

- Spark-proof motors to prevent electrical discharges.

- Dust-tight or gas-tight enclosures to stop hazardous materials from entering.

- Surface temperature controls to prevent hot spots that could ignite vapours or dust.

Without certification, equipment can create hidden risks. Imagine a shredder operating in a Zone 22 (where explosive dust atmospheres may occur infrequently). If its switches are not protected against sparking or its housing is not sealed, a small fault could provide the ignition source for a dust cloud.

Certification is not an optional extra, it is a legal requirement and a cornerstone of safe operation. Navigating the details of standards and matching them to the reality of your processes requires expertise, which is why choosing the right consultancy support plays a critical role.

Best Practices in Selecting Size & Volume Reduction Equipment

Selecting the right equipment is not simply about processing speed or durability, it must be guided by a thorough understanding of hazards and zones. That’s why the first step should always be to engage a trusted consultancy to carry out a DSEAR risk assessment.

An experienced and knowledgeable consultant will:

- Accurately define zones to uncover all potential risks.

Advise on certification requirements for shredders, mills, crushers, compactors, or briquetting systems. - Recommend supporting safety measures, such as extraction systems, explosion venting, or monitoring for temperature and pressure.

- Develop maintenance and cleaning strategies to reduce long-term build-up of dust or other hazards.

Once this groundwork is complete, suppliers can be approached with a clear, informed specification. This ensures that the equipment sourced is not only compliant, but also suited to the specific environment in which it will operate.

When correctly specified and integrated, shredders, crushers, mills, compactors, and briquetting systems achieve what they are designed to do: reduce material size and volume efficiently while maintaining safe, compliant operations.

Conclusion

Size and volume reduction equipment is vital for productivity in bulk material handling, but without proper assessment, it can also be a source of hidden danger. The key to safe operation lies in three steps: accurate zone classification, certified equipment, and ongoing risk management.

By starting with expert consultancy, businesses can be confident they are making the right choices from the outset. This not only ensures compliance with DSEAR but also protects teams, facilities, and reputation.

With the right guidance and the right equipment, efficiency and safety go hand in hand.