When installed directly on the production line, automated moisture monitoring significantly reduces human error inherent in time consuming and out of date manual processes. Incorporating moisture measurement during production allows the user to create a closed-loop process and have full control over the production line. While several methods are available, the use of near-infrared (NIR) technology can produce a high return on investment (ROI).

Benefits of moisture content measurement equipment and processes

Moisture measurements are used throughout many manufacturing processes, from examining incoming raw materials, to ensuring final product quality and shipping weight. Moisture ranges outside of tolerance can inhibit the production process and even create wear and tear on other equipment. Each phase of the manufacturing process runs more efficiently and profitably with accurate moisture content.

In the past, many firms have relied on manual moisture testing and measurement methods, but these old school methods are notoriously subject to errors and are a known primary cause of many production issues. Manual moisture monitoring essentially requires a laboratory setup in a controlled environment. Samples need to be immediately sealed in plastic or glass jars once taken from the production line and taken for testing. The moisture content will naturally change every minute that passes once the sample is removed from the production line, throwing off the final results. Older manual testing methods (for example, ovens) often lose the ability to test samples accurately.

Moisture control systems automate and accelerate many of these mundane inspection-based quality tasks. Adding the automation of moisture detection throughout the production process can eliminate the frequent mistakes and allow for a closed loop process when tied directly into a programmable logic control (PLC) system. With critical points of production being monitored for moisture content, everything from the raw material to the finished product can be precisely monitored for accuracy and quality.

In addition, moisture measurement systems tied into the process controller can easily detect out of spec products so they can be dealt with immediately to ensure additional product is not affected. When issues are identified early, corrections can be made long before an imperfect or contaminated product reaches consumers.

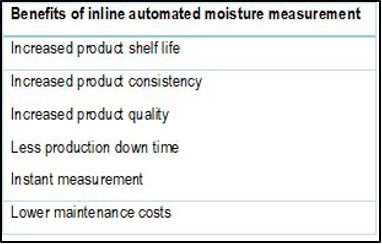

Real-time process control with moisture detection provides true product data that can be used to improve operation efficiency. This reduces wasted effort and materials, and decreases the frequency of downtime, manual intervention, and defective goods. Real-time control of moisture leads to significant cost savings, in terms of energy, spoilage, down time, quality control rejects, and customer complaints. For processes that can be closely controlled using real-time measurements, in-line systems in feedback-loops often produce a high return on investment (ROI).

Automated in-line moisture measurement technologies

Several technologies are available for automated in-line moisture measurement. One such method that greatly improves quality is near-infrared (NIR) technology, which uses a simple light source for measurement. NIR moisture measurement is a fast, non-destructive, non-contact method of measuring and controlling moisture content that offers clear advantages over the traditional methods, including ease-of-use, elimination of hazardous chemicals, and increased efficiency of product testing. With NIR analysis, all manual steps of collecting, drying and accurately weighing samples are eliminated. When incorporated throughout the production process, NIR technology greatly improves quality.

NIR moisture sensors give manufacturers the ability to adjust moisture levels on real-time information, lowering raw material and fuel costs, higher yields, and more uniform products. Allowing the moisture measurement to be automated with high and low alarms built into the system allows for personnel to focus on other aspects of the process while maintaining accuracy in moisture control. It reduces human error, increases plant efficiency from the automated process and frees up man hours for other tasks that cannot be automated.

Since NIR depends on light reflection, its one key disadvantage is associated with its use with products that are largely or completely carbon black. The technology still works but may require tweaking or adjustments.

In addition to NIR, other automated technologies are available. For example, microwave technology sensors are often used in wood biomass applications, but they tend to lose accuracy quickly and may not give the same results every time. Those reliant on accuracy to a specific percentage must steer away from microwave technology. Another option is nuclear technology. While extremely accurate, cost is a major disadvantage; nuclear options may be four to five times the cost of NIR technology.

NIR moisture measurement improves a wide variety of processes

Automated inline moisture measurement using NIR technology is widely used in pet food, human food, minerals, bulk materials, and wood/biomass applications, as well as paper and plastics, bioenergy, and textiles and nonwovens. In recent years, it has been used for dried distiller grains (DDG) in the production of ethanol. Here are a few examples showing how the technology helped manufacturers improve their manufacturing process.

Automated inline moisture measurement using NIR technology is widely used in pet food, human food, minerals, bulk

materials, and wood/biomass applications, as well as paper and plastics, bioenergy, and textiles and nonwovens.

Paper industry

A manufacturer was having issues with controlling the moisture on different types of paperboard using a manual sampling method brought to a lab for testing. Their lab method consisted of weighing the sample, drying it at a low temperature for a certain amount of time, and then weighing it again. They used the lost weight to calculate the amount of moisture of the product. Unfortunately, this method takes a lot of time; if the product is out of the required moisture range it was too late to correct it, representing a loss of energy and product that had to be reclaimed.

After installing a NIR online moisture sensor (MoistTech IR-3000) the company was able to monitor the moisture continuously at a +/- 0.1 percent accuracy, which enabled them to make required adjustments to their dryer speed or temperature. The sensor was also integrated with their PLC. Not only can the equipment measure moisture, but the sensor can also accurately measure the thickness of the water-based coating the manufacturer applies to some of their product. Installing the sensor allows the facility to act immediately on any issues that might arise during production.

Coating/paper

Coating application problems are often not detected until after the process is finished. Typical manual processes only average the entire process and cannot detect missing or uneven coatings. Prior to the installation of an NIR sensor, a paper company used redundant systems for measuring consumption, which often resulted in more confusion. The new sensor (MoistTech IR-3000), combined with the programmable linear slide, provides the plant with real time coat weight readings across every part of the substrate. Problems are corrected early in the process, resulting in substantial reductions in waste. The company reports that set up times have been reduced by as much as 50 percent, because lab tests are no longer required to verify coat weights.

Potato flakes and potato chips

At one facility, cooked mashed potatoes are dehydrated into flakes and toted for further processing into finished flavored potato product. The facility’s existing moisture measurement method consisted of taking samples at timed intervals and testing them in a lab. By the time the samples were taken and the data received, adjustments to the process were delayed, making it difficult to control the product in specification. The company had attempted to resolve the issues by making manual adjustments after receiving lab results. After adopting use of in-line NIR technology, sensors are monitoring the moisture and adjusting the speed of the drum dryer by changing the frequency of the motor variable frequency drive (VFD) based on the moisture set point.

Packaging

A north-eastern printing and converting facility that specializes in heavy weight laminated paperboard for club store

applications, was experiencing curl or warp in the finished product when laminating paper substrates. Attributing the issue to unequal moisture in the top and bottom sheets, the company had attempted to resolve the issues by using a coat weight sensor to measure coat weight of laminating adhesive. They also set standard work processes for tensions, coat weights, and steam settings, and relied on certificate of conformance (COCs) from the paper vendors to set equal moisture targets in the top and base sheets.

After adopting a NIR reading device to read moisture in the two webs of paper before laminating, they estimated a reduction of 10-15 percent of monthly wasted product. They found that the paper moisture was varying even from the COCs provided by the vendors, causing continued warp issues. Once they collected data for moisture content, they were able to find which moisture levels work and which caused issues. They charted the variation data and shared it with paper vendors, asking them to tighten up their tolerances for moisture. They then set targets for moisture and continue to measure them, rejecting anything outside this target with appropriate tolerances outside of mean values. This enabled the company to significantly reduce warp issues and continue to tweak their processes with a goal of completely eliminating warping.

Fuel source from waste (biomass)

Waste products are often turned into pellet fuel for heating electric power plants, schools, and homes. Wood pellets are made from compacted sawdust or other sawmill waste products, as well as palm kernel shells, coconut shells, rice husks, wheat, and grasses. Manufacturing wood pellets requires refining, drying and blending of wood waste prior to entering the pellet press. Measuring moisture throughout the wood pelletizing process will produce pellets at a specific moisture percentage, preventing products that are too wet or too dry.

Nate Harris, President of Custom Pelleting Services, explains, “One metric that is often overlooked or, rather I should say undervalued, is the moisture rate of the biomass. I have found that changing the moisture percentage even by as little as 1 percent makes a noticeable difference in the pellet quality both in the durability and in the sheen.” He adds, “We have found that by using MoistTech’s IR3000 moisture sensors, we are able to make adjustments to the programming of the dryer system to provide a more consistent biomass moisture rate in real time that directly correlates to a higher production capacity and a better quality pellet.”

Improve quality by incorporating automated moisture measurement

Quality and consistency are crucial when it comes to maintaining a manufacturing line. Implementing an automated moisture control sensor instantly reduces waste and energy costs as well as improves the efficiency of the line. In many cases, manufacturers can achieve a very favorable ROI.