Sensors can be used directly in the field or at the process line, eliminating sample extraction and testing in distant labs, providing instantaneous results versus long lead time lab tests. The quick and frequent data can be input in a control loop to perform assessment and implement immediate decisions. Sensors take the form of hard sensors, which are physical devices, and soft sensors, which are software-based and use parametric data.

A physical sensor is a device that detects the input stimulus, which may be any quantity, property, or condition from the physical environment, and responds to a measurable digital signal. For example, the input stimulus could be pressure, force, flow, light, heat, motion, moisture, or any one of a vast number of other environmental phenomena. The response output is usually an electric form of a signal, like voltage, current, capacitance, resistance, frequency, etc., which is converted to readable display or transmitted by electronic means over a network for reading or dissemination.

Due to technological advancements in sensor components and the operational software, hard sensors have come a long way. They can be miniaturized to use in tight spaces and low weight applications, robust for use in harsh settings, easy to install and run, and provide simple result readouts such as pass/fail format, making them operatable by many without the need for subject matter experts. But in recent years, the sensor’s instrumentation has remained fairly steady against the accelerated digital transformation, automation & controls. Today, this combination forms the basis of big data, cloud computing, artificial intelligence, intelligent robotics, automated smart control applications, and Internet of Things (IoT).

In bulk solids handling, sensors have a pivotal role to play throughout the stages of storage, transfer and processing; processing comprising of solo unit operations or multi-unit operations working in tandem towards a common goal. Modern day manufacturing, which is characterized by real-time output, automated control systems, and high data fidelity, is designed to achieve operational efficiency, worker and infrastructure safety, and consistent product quality at reduced costs and at faster rates.

Data from sensors is valuable, but the feedback to control the process is where the strength of sensors shine. To develop a sensing and control platform, broadly speaking, the first step is to identify which variables need to be monitored. This is followed by the selection of sensors that can measure the identified variables. After this, the sensors – physical devices and parametric – must be integrated into a centralized control system along with establishing threshold limits that trigger notification and/or automated actions to bring excursed processes back in control. The automated actions involve the continuous adjustment of parameters in proactive and reactive manners. The overarching layer above is communication networks that enable the transfer of data between equipment, sensors and the control system, engaged via a user interface.

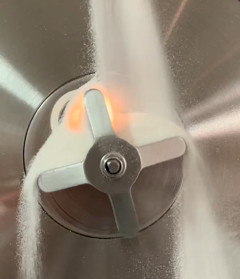

After assessing the desired variable to be monitored and an appropriate sensor has been determined, its implementation is a non-trivial task. The placement of the sensor comes with the following considerations: spatial position, location within the equipment, manner of measurement for optimal acquisition of the raw signals, its representation of the bulk material, frequency of measurement and sample size. The placement of the sensor should ideally be non-intrusive to the bulk solid flow, any protrusions into the flow of material can themselves hinder/stop flow if not positioned correctly. Figures 1 and 2 illustrate examples of sensor implementation.

Sensor Applications in Bulk Solids Handling

The common types of sensors utilized to monitor bulk solids are temperature, humidity, pressure, flow, force, proximity, and spectral. These may be used to monitor the material itself, the process conditions such as ambient air temperature/RH (headspace, motive air, effluent); weights and flow rates of incoming raw materials or process streams; perhaps composition such as NIR or other PAT; torque or power for equipment to move or mix materials.

Bulk solids flowing through equipment such as hoppers, feeders, silos and transfer chutes require reliable flow as this has safety, environmental, quality and monetary impacts. A consistent flow rate is influenced by several factors, categorized into bulk solid properties, equipment design and processing conditions.

The reliable flow comes from the selection of the right equipment and a knowledge of the properties of the material that the equipment will handle for the intended application. Depending on the application, the ability to know how the bulk solid is flowing in real-time is sometimes limited or nil. Often this knowledge comes too late in the form of an undesirable outcome, following which a reactive approach is required as a correction. Typical indicators such as feeder speed provide insights into changes to the bulk solid after the fact, but with additional sensing capabilities, information can be acquired early and frequently so necessary actions can be undertaken early or as it is happening, via the control system.

The following examples demonstrate how the synergy of material properties, reliable equipment and sensing can ensure a process is in control:

- Qualitative monitoring to detect the presence or absence of bulk solid in a bin/silo: A level sensor strategically placed within the hopper, can control the dispensing of bulk solid from an upstream silo through a feedback control.

- Semi-quantitative determination of bulk solid density: For fine powders in particular, which are prone to two phase (air : solid) flow behaviors, a spectral sensor can be used to get a sense of state of aeration of a powder bed by a change in the spectral baseline when the powder density changes to proactively modulate the feeder speed to ensure a consistent flowrate of powder.

- Extending the above knowledge, the transfer of powder via a chute between unit operations can be evaluated by laser diffraction for obtaining the powder’s particle size distribution, correlatable to its state of aeration and, therefore, permeability. This, in combination with empirical data, can be used to assess for process variations, incoming material variations, environmental changes, etc. The assessment can be used to accordingly modulate the process, via the control platform, to ensure the process is in control.

Conclusions

One would assume that having selected the right equipment for the operation by choosing the appropriate material of construction and the correct geometry for the intended bulk solid, the outcome will be a reliable operation, as long as the boundary conditions of temperature, relative humidity, time, process parameters are maintained. This is generally true but not often the case, as variations and excursions tend to occur more often than one would think. A change in any of the boundary conditions or in the incoming material or an adjustment to the equipment can very easily disrupt the equipment operation, therefore interrupting the overall process. Early detection of the changes is critical in industries such as pharmaceuticals where the out-of-specification content uniformity of the final product can impact patient health, in addition to causing significant monetary loss. In the cement industry, knowing if fly ash has deaerated sufficiently can prevent its “flooding” out of a feeder and becoming a worker safety concern. In these situations, the presence of a monitoring method can provide an upper hand to these industries.

For achieving the most optimal operation, a proactive and risk-benefit approach involving multidisciplinary team of experts will ensure companies can ensure stable operations, improve reliability, increase production and reduce costs.