“The safety of the plant, the products, and above all the operator is our highest priority.”

This sentiment is echoed by most companies aiming to automate critical raw materials. Many substances—such as polypropylene, metal powders, coffee, milk powder, additives, and others—are highly sensitive in terms of explosion protection and product integrity. These sensitivities may include low ignition energies, oxidation risk, or the preservation of aroma and shelf life. In such cases, processing under an inert gas atmosphere becomes the method of choice.

However, it’s not enough to simply understand how a material is conveyed — deep knowledge of the raw material’s behavior under varying conditions is essential. This is where AZO’s raw material expertise becomes invaluable. Furthermore, when handling protective gases, extensive safety precautions for operators must be implemented by the plant operator. Close collaboration between plant manufacturer and operator is crucial during risk assessment and system design. Requirements differ widely across industries, and so do the solutions.

Example: Polypropylene Powder

In plastics processing, polypropylene powder can contain residual propylene gas after production. This gas may gradually be released during storage, conveying, or dosing—creating a potential explosive atmosphere. To prevent this, the oxygen content must be reduced below the ignition threshold. Therefore, raw material automation in a nitrogen atmosphere is the safest approach.

The material is conveyed from the reactors to a weighing hopper and then to a buffer container, using nitrogen pressure conveying. The pressure is provided by a separate nitrogen network. Components such as the weighing hopper and buffer container must be equipped with purge filters, discharge aids, and aeration nozzles.

The buffer containers — often holding a day’s supply of polypropylene powder — are then emptied and transferred via nitrogen conveying to blending silos, where compounding takes place. Additives such as UV stabilizers, peroxide pellets, and antioxidants are fed and dosed separately. A differential dosing scale blends the ingredients, creating a batch ready for granulation.

The nitrogen gas is filtered and recirculated, and oxygen levels are constantly monitored throughout the system. If a critical threshold is exceeded, conveying stops and the system is flushed with inert gas until a safe level is restored.

This closed-loop gas system ensures both cost efficiency and safety. AZO’s decades of experience, broad product portfolio, and in-house raw material lab allow for detailed analysis and system design tailored to each material’s flow and product characteristics.

Example: Metal Powders in Additive Manufacturing

Metal powders used in additive manufacturing (3D printing) also require inert gas environments—typically nitrogen or argon—for safe automation. Given the potential health risks, operator protection is essential. While the 3D printing industry is still evolving in terms of standards, awareness for safety has increased significantly (e.g., VDI 3405-1).

In the past, powders were handled openly under exhaust hoods. Operators had to wear full protective gear when feeding the materials manually—since the powders are respirable and hazardous. In response, AZO has developed innovative technologies to safely and efficiently automate the handling of metal powders.

AZO offers systems in which powders are transferred into the process via a glovebox under inert gas atmosphere. The powder can arrive in any manually handled container, eliminating the need for full protective gear. The sealed glovebox ensures maximum operator safety.

The inerting of the entire system achieves two goals:

- Prevention of oxidation, which would render the material unusable

- Lowering oxygen levels in the potentially flammable powder-air mixture to prevent dangerous reactions

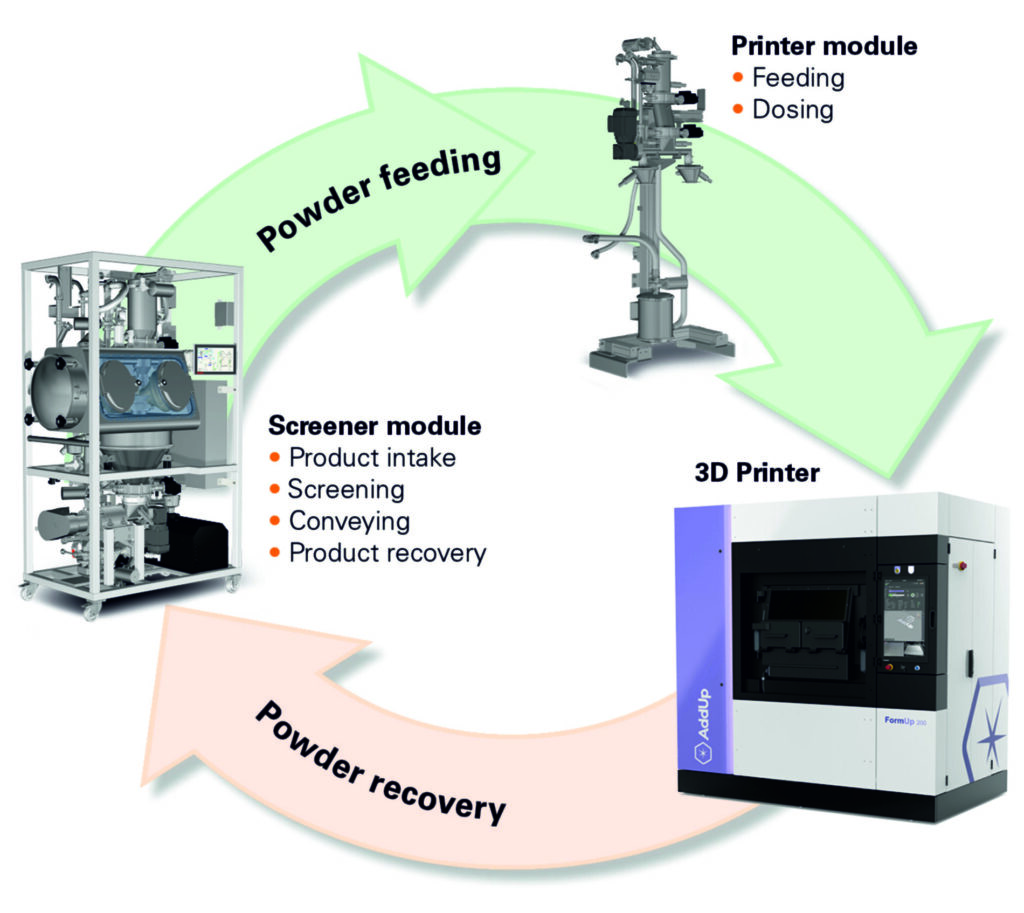

Complete System for 3D Printer Feeding AZO’s modular system consists of:

- Sieve module (including glovebox, storage container, sieve, and pneumatic conveyor)

- One or more printer modules, which can be connected directly to 3D printers

This flexible system supports single-printer setups and large-scale printer farms.

The metal powder is first sieved, then pneumatically conveyed to the printer’s powder inlet. Used powder scraped from the build platform is returned to the sieve module—entirely within an inert gas environment.

To minimize inert gas consumption, the system operates in a closed-loop. After a print job, unsintered powder is conveyed back into the prep system for reuse. Fresh nitrogen can be added as needed to maintain optimal atmospheric conditions.

If reuse of powder is not permitted—due to regulatory, contractual, or internal guidelines — the material can still be safely discharged under inert gas into dedicated containers and removed via a sealed transfer door.

AZO combines the necessary technical expertise in inert gas automation with deep knowledge of raw materials and their characteristics—regardless of whether it’s a greenfield, brownfield, or retrofit project. From small enclosed systems to large, highly complex conveying plants, AZO delivers solutions that meet the most demanding safety and process requirements.