Whether dealing with sterile drug formulations or nutritional blends, ensuring uniformity while maintaining material integrity and preventing contamination remains a central concern. While many types of mixers and methods exist, few offer complete control over the complexities of modern powder processing.

As demand for higher safety standards, sterility, and flexibility grows, more attention is being given to contained, closed-loop systems that eliminate open handling and ensure reproducibility. Among the most promising advances in this space are technologies that integrate powder transfer, mixing, and containment in a single, scalable platform.

Powder Mixing: A Process Fraught with Complexity

Powder behavior is influenced by a wide range of physical properties—cohesiveness, bulk density, moisture content, particle size and shape—each of which can affect flow and blend uniformity. When these properties vary significantly between materials, segregation becomes a risk, especially during handling, transfer, or prolonged mixing.

Mechanically, mixing occurs through three primary mechanisms:

- Diffusive mixing: particles roll and slide over one another.

- Shear mixing: layers of powder slip along defined planes.

- Convective mixing: bulk movement and circulation of the entire powder bed.

In real-world scenarios, an effective mixing process may involve a combination of all three. However, optimizing the balance between mixing rate, uniformity, and avoidance of segregation is a continual challenge. This is particularly true for blends with active ingredients at low concentrations, materials sensitive to heat or oxygen, or substances classified as highly potent or explosive.

Traditional mixers—tumble blenders, paddle mixers, or high-shear agitators—each have their place, but they often require trade-offs in terms of containment, cleanability, flexibility, or mechanical stress on the product. The industry has increasingly turned toward solutions that offer greater control, particularly under aseptic or toxic conditions.

A Shift Toward Closed and Aseptic Mixing

Recent years have seen a steady shift in powder processing strategies, especially in sterile manufacturing environments. EU and FDA guidance stress the importance of fully closed systems in preventing contamination—especially for injectable powders, plasma-derived products, or sensitive nutritional ingredients.

Conventional open or semi-closed systems no longer offer sufficient protection against contamination risks. Moreover, as product portfolios become more diversified, manufacturers need systems that can manage different batch sizes and materials without lengthy changeovers or cleaning validations.

This is where closed, vacuum-assisted mixing systems present a clear advantage—offering precise control over environment and process conditions, while preserving the physical characteristics of delicate materials.

Dec’s PTS Technology and the PTS Batchmixer®

One notable advancement in this field is Dec’s Powder Transfer System (PTS), a vacuum-based technology designed for fully contained transfer of powders. Originally developed to safely convey toxic materials, the PTS has become the foundation of an integrated approach to powder handling that includes transfer, dosing, mixing, and discharge—all in a closed manner.

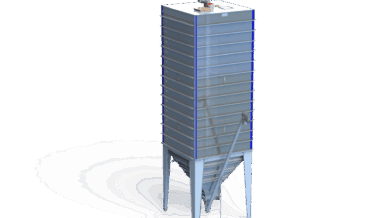

Built on this technology, the patented PTS Batchmixer® offers a unique solution for efficient and safe powder mixing without the use of internal rotating components. Instead of mechanical agitation, the system relies on controlled powder circulation driven by the PTS. Two tangential inlets introduce powders into a vessel, where an integrated central deflector promotes uniform distribution of materials.

PTS Batchmixer® Fully integrated powder blender

This approach delivers several clear advantages:

- Gentle yet thorough mixing, with no particle damage and no risk of overheating

- No moving parts inside the mixing vessel, simplifying cleaning, reducing maintenance, and eliminating cross-contamination risks

- Fully closed operation, making it suitable for sterile or toxic processes

- High turndown ratio, enabling efficient mixing from 10% to 100% of vessel capacity

- Quick and complete discharge, minimizing product losses and simplifying batch traceability

- Inert gas capability, allowing safe processing of oxygen-sensitive or hygroscopic materials

Thanks to its modular design and broad size range (2 to 6000 liters), the PTS Batchmixer® can be used across scales—from formulation development to full-scale production. It can extract powder directly from drums, bags, or upstream process equipment and discharge to packaging or downstream systems, all without breaking containment.

Its hygienic design meets strict cGMP compliance, and the system supports CIP/SIP procedures using 90 °C hot water or steam.

Importantly, the PTS Batchmixer® allows for introduction of additives during mixing and includes options for inline sampling, further supporting real-time quality control and process efficiency.

Integration with Powder Decontamination Technology

Sterile processing does not begin and end with mixing. In many cases, powders must first undergo decontamination—especially when used in parenteral formulations or high-risk food ingredients. However, traditional decontamination methods such as dry heat or high-temperature short-time (HTST) treatment can be problematic for powders, particularly those with porous structures or heat-sensitive properties.

To address this, a new generation of Vacuum-Steam-Vacuum (VSV) technologies has emerged. Developed in collaboration with ETH Zurich, this system subjects powders to short bursts of saturated steam under vacuum conditions, achieving high microbial inactivation without compromising product quality.

This method has proven effective for ingredients used in nutritional powders—where even trace microbial contamination can pose serious risks. The VSV module can be directly integrated with a closed PTS Batchmixer® line, allowing manufacturers to move from decontamination to blending and discharge without exposure to the external environment.

A Technology Aligned with Industry Needs

PTS-based mixing represents a significant advancement for manufacturers who need to meet increasingly stringent requirements for safety, sterility, and scalability.

Such systems support:

- Uniform blending of powders with varying particle sizes and densities

- Fully contained, aseptic and toxic ingredient manufacturing processes

- Scalability from pilot to full production scale

- Flexible batch sizes for multi-product facilities

- Rapid cleaning and reduced downtime between campaigns

By eliminating open transfers and reducing manual handling, they also support broader trends in automation and digital traceability, key components of modern pharmaceutical and food production strategies.

Conclusion

Powder mixing continues to be a critical and technically sensitive step in the production of sterile and highly potent materials. As regulatory expectations rise and product complexity increases, manufacturers are seeking solutions that go beyond traditional mechanical mixers.

Systems based on Dec’s PTS technology, including the PTS Batchmixer®, represent a thoughtful and validated response to these needs. Through closed, vacuum-driven processes, these solutions provide a high level of containment, batch flexibility, and process control—all essential for ensuring product quality and operator safety.

For manufacturers across pharmaceuticals, nutraceuticals, and food sectors, integrated solutions that handle everything from decontamination to final mixing in a contained environment are not just a benefit—they are rapidly becoming the new standard.