From South Korea to South Africa and Sweden to Singapore, Ajax’s approach to solids handling and processing has helped manufacturers of plastics and polymers all over the world – by recognising that each material and process has its own, unique requirements.

Investing time and effort in material testing at the beginning of the project provides an understanding of the material and the application which is essential to producing a mixer design that works with their needs and allows any potential difficulties to be addressed before they occur. In the long run it’s always quicker and more cost effective to get the design right the first time than try to retrospectively adapt an existing design. However, before considering how the material affects design, it is first necessary to think about the process and whether batch or continuous mixing is best suited?

Batch Mixing

Both batch and continuous methods are capable of efficiently producing homogeneous mixes, but batch mixers offer an advantage to processes where it is easier to measure and load precise quantities of each ingredient in turn as well as monitor the quality of each batch.

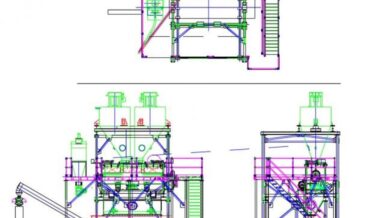

For one global chemicals company Ajax has supplied a range of vertical screw blenders for polymer powder production across production plants in the UK and South Korea. The blender’s capacities range from 5 to 8 tonnes but both utilise vertical ‘fountain’ mixing screws to quickly combine batches of polymer powder and additives.

The 8 tonne capacity blender uses a pair of fountain vertical mixing screws in combination with the hoppers internal mass flow design, determined through shear testing, to efficiently blend the powders by optimising flow behaviour and delivering a high recirculation rate. The blending flow pattern achieved also helps to counter any tendency for segregation, a potential issue when handling dry granular materials with variable particle sizes.

Discharge to the blender’s two alternative outlets is aided by the screw’s rotation, enabling the blender to completely empty a batch within 5 minutes. A further benefit of the mixer’s design is a reduced headroom requirement. Combined with the small footprint required, this allows the blender to hold and process large volumes of powder and additives within a relatively small area.

Continuous Mixing

In contrast to batch mixers, continuous screw mixers allow sequential operations to be avoided with materials fed into the mixer at a steady controlled rate. Working with a smaller cross section of material progressing within a continuous mixer means the machine takes up less space.

Another advantage of continuous mixing over batch is the opportunity for greater production flexibility. When leading Swedish plastics company, Polykemi AB, found their batch mixer lacked the agility to best satisfy increasing customer demand for more varied mixes coupled with a desire to reduce downtime (in particular cleaning time) they decided to investigate a continuous process.

After a period of running trials and testing, Polykemi decided to go ahead with a twin screw continuous mixer from Ajax Equipment to combine plastic granulates with additives and pigments for a range of extrusion machines. The twin ‘U’ profile mixer features two screw augers with LynFlow paddle blades for effective mixing of the granulates greater as well as providing Polykemi with control over the homogeneity and quality of the mixed granulate compound and the ability to process varying overall quantities and rates. As a result of the efficient mixing action, the work input is reduced, helping to minimise any particle attrition.

To ensure easy cleaning of the machine, the mixer has an almost food quality standard of finish and quick release screws. These features have significantly reduced the downtime needed for cleaning equipment between production runs.

A further benefit of quick release augers is a short changeover time. One set of screws can be easily removed and another designed for other mixes installed and production swiftly resumed.

Getting the Right Mixer

Although often presented as rival options, the different benefits of batch and continuous mixers should indicate which is the right technique for your process. It should be noted that recent trends may point towards continuous operations offering more flexibility and therefore tending to be operationally desired. This is an area where Ajax has continued to develop capacity and capability with a range of active mixing friendly casing profiles and auger forms which ensure even better mixing performance and cleanability.

Whichever is chosen, screw mixers are highly effective and, provided they are designed and utilised well, can provide decades of reliable service.