Graphite, carbon black, activated carbon, and carbon fiber-reinforced plastics and composites are seeing increasing use in battery, electronic, automotive, aviation, and defense applications, among others.

Within this niche market, product uniformity and consistency are critical to performance, requiring a high level of precision during production. In this way, mixing plays a vital role, maximizing uniformity in both finished and intermediary products.

As manufacturers continue to develop and refine their product offerings and production lines to fit market demands, many are finding that the pin mixer, a type of horizontal mixer, offers the ideal capabilities for achieving tighter quality control and greater process efficiency.

Mixing’s Essential Role in Carbon Processing

Specialty carbon producers rely on mixing to accomplish two fundamental aspects of carbon production: enlarging particle size distribution (PSD) and maximizing physical and chemical uniformity.

Increasing Particle Size

With an ultra-fine particle size, carbon materials are incredibly dusty, causing several issues for producers:

- Difficulty in handling, feeding, transporting, packaging, storing, and applying without product loss

- Housekeeping and safety risks associated with fine particulates

- Inability to achieve uniform processing in downstream equipment due to dusting, clumping, and inconsistent feeding/flowability

- Poor bed permeability in reactors or equipment relying on gas-to-solid or liquid-to-solid contact

For these reasons, enlarging particle size is a top priority for carbon producers. By blending fines with a liquid binder or water, producers can achieve dust-free agglomerates or granules that are highly flowable, significantly improving handling, storage, and performance characteristics.

As an example, biochar, a precursor to activated carbon, requires processing in an indirect rotary kiln or other thermal device for activation. If the material were to be processed as fines, the surface area exposed to the heating medium would be minimal, resulting in uneven activation and poor product quality.

By mixing and granulating the material prior to the rotary kiln, however, producers can ensure uniform surface area exposure and improved heat distribution through the material bed.

Ensuring Physical and Chemical Homogeneity

Physical and chemical uniformity are a cornerstone of specialized carbon products; from fillers to battery chemicals, producers rely on physical and chemical precision in their feedstocks, intermediaries, and finished products to yield consistent product quality and performance.

Fine particle size distributions make uniform processing difficult, limiting consistency and performance, but this isn’t the only challenge a lack of uniformity presents.

Producers including functional additives to improve product formation, handling, or performance must be able to ensure a homogeneous blend of all components for physical and chemical uniformity to achieve target parameters such as a specific porosity, conductivity, or reactivity, etc. This uniformity is especially important when particle surfaces must be evenly exposed to binders or chemicals in downstream activation.

Proper mixing ensures the physical qualities – size, moisture content, bulk density, etc., as well as the mixture’s chemical composition, are uniform throughout.

Why Pin Mixers for Mixing Carbon Products?

Pin mixers have long been used throughout the carbon products industry, owing to their superior dedusting capabilities. They are incredibly effective in blending ultra-fine materials with a liquid binder to produce a homogeneous, de-dusted mixture, as well as uniform agglomerates in the range of 20 to 60 mesh (for larger pellets in the range of 40 mesh to ¾” the pin mixer can be followed by a disc pelletizer).

The pin mixer’s effectiveness is largely due to the centrifugal force the mixer imparts on materials.

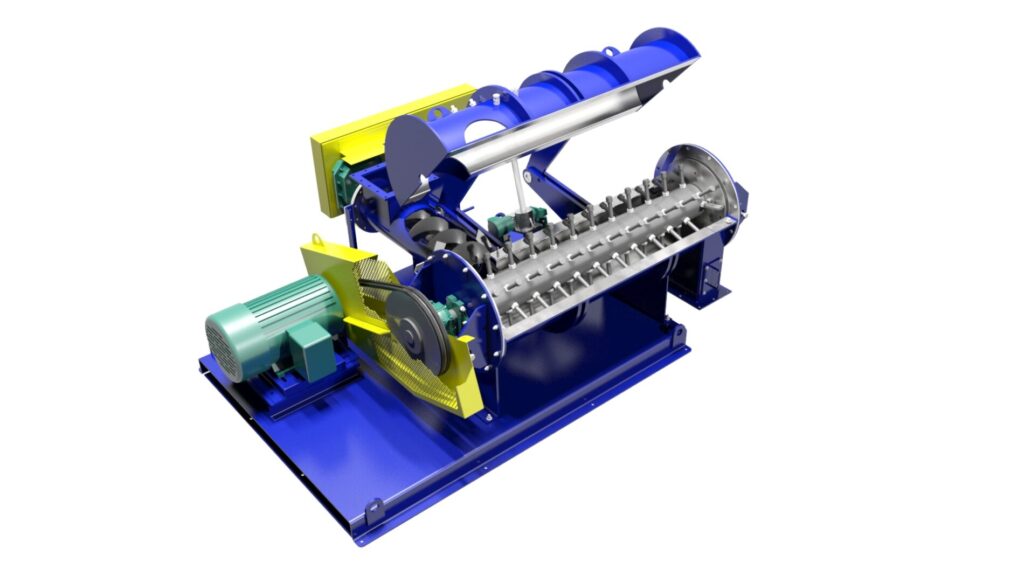

How Pin Mixers Work

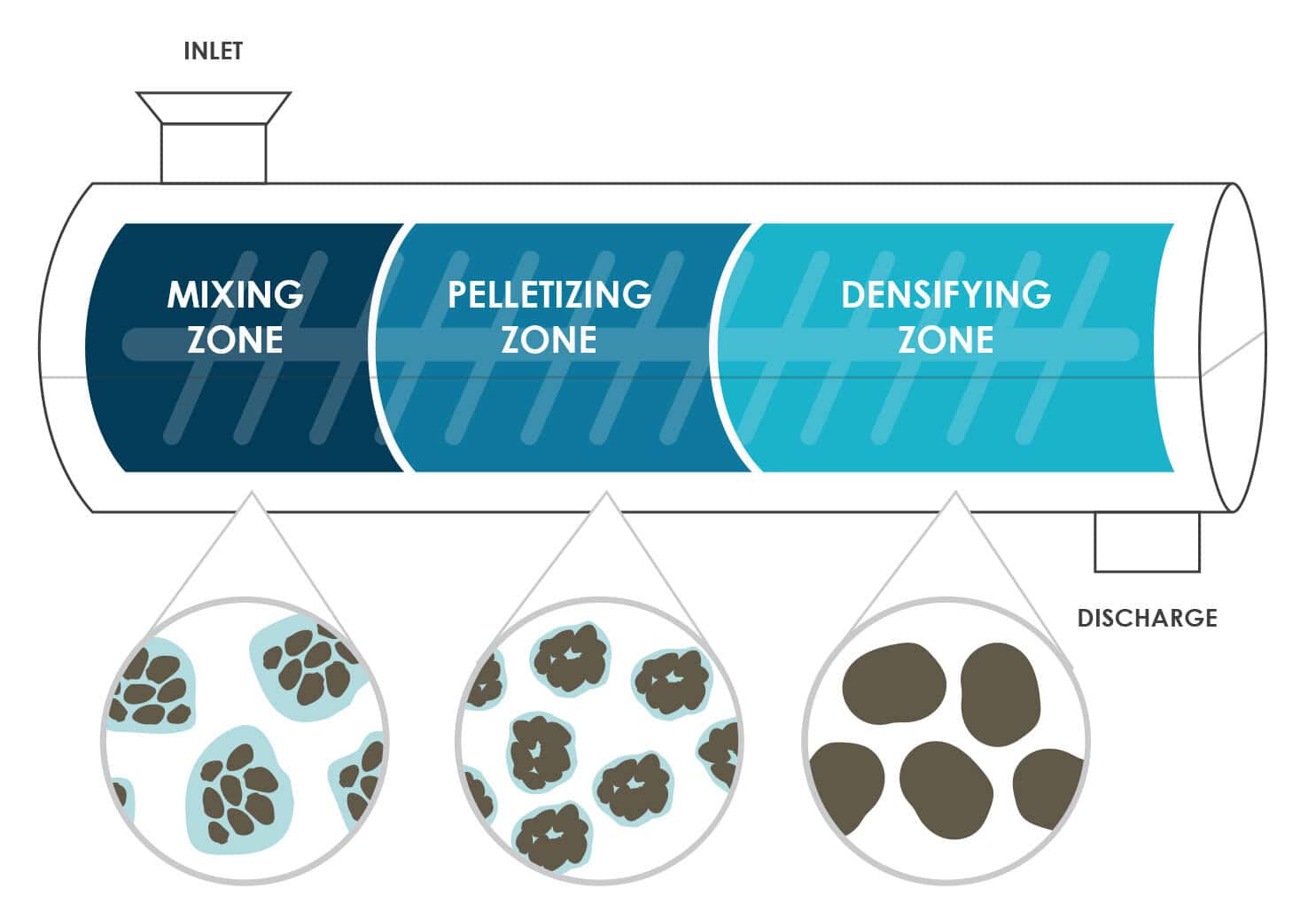

The pin mixer consists of a horizontal cylindrical trough, through which a single shaft fitted with pins spins at several hundred rotations per minute (RPM). Material is fed into the inlet, where it is taken up by the rotation of the pins. Spray ports strategically positioned inside the trough cover introduce and distribute liquid binder at a predetermined feed rate.

As material moves down the length of the mixer, the centrifugal force within the mixing trough causes particles to form small, condensed agglomerates, which increase in density as they continue toward discharge. Material is processed for a predetermined retention time – typically in the range of 10 to 20 seconds, based on desired product qualities, at which point it is discharged from the mixer.

The pin mixer’s unique action ensures:

- Thorough wetting and uniform moisture or additive distribution

- De-dusted material (conditioned fines or small agglomerates)

- Homogeneous consistency and physical qualities

- Non-varying chemical composition

- Early densification

Densification Through Motion

The ability of the pin mixer to lend these qualities is not the only reason why pin mixers are preferred for carbon products. One of the primary differentiators of the pin mixer is its ability to provide mechanical densification over chemical densification.

A key requirement in many advanced carbon products is purity; some products may be required to be free of impurities in the form of additives such as binding agents, which are often required in non-pressure (agitation) agglomeration processes to bind particles together and yield the desired bulk density.

The pin mixer densifies particles through motion (i.e., the intense centrifugal force inside the mixing trough), allowing producers to meet purity goals with minimal additive inclusion. In many cases, only water, which is later driven off via drying or heat treatment, is added to assist in agglomerate formation, while still achieving the required bulk density.

Process Development Highlights Need for Flexibility and Customization

One of the industry’s current challenges is the highly specialized nature of advanced carbon products. From catalysts to battery chemicals, biochar, and more, carbon materials require varying but precise specifications depending on their use and the exact conditions of their intended application.

This presents two challenges to producers:

- Identifying the specific combination of qualities that will reach handling and performance goals

- Establishing a process that can reliably produce those qualities at scale

As with many processes, the path to production at scale is often unclear. Significant exploration around developing specialized carbon products and the processes to manufacture them is ongoing, with testing facilities such as the FEECO Innovation Center offering a critical outlet for process development work involving pin mixers (among other equipment).

The Innovation Center is equipped with both batch- and pilot-scale pin mixers for every stage of process development, from illustrating proof of concept and proof of process to optimizing the continuous process. Rental units are also available for in-house R&D work.

Producers can produce small samples for field testing, allowing them to identify key parameters such as:

- Moisture content

- Bulk density

- Particle size distribution

- Chemical composition

- Flowability

- Attrition

The system parameters required to yield these results are also established and typically include:

- Equipment configuration

- Feed and product flow rates

- Pretreatment requirements, if any

- Spray rates and locations

The Innovation Center offers a range of complementary equipment relevant to processing carbon materials as well, including disc pelletizers and agglomeration drums, pugmill mixers, rotary dryers, and rotary kilns. This means producers utilizing a dryer or kiln after their mixing step can test both the agglomeration and thermal steps of their process from start to finish.

Conclusion

As the carbon products industry continues to evolve, the pin mixer is emerging as a critical enabler of progress. Its ability to blend and densify ultra-fine carbon materials into uniform, dust-free agglomerates makes it indispensable for achieving consistency, purity, and performance in today’s high-value carbon products.

Whether applied to carbon black dedusting, activated carbon preparation, graphite processing, or emerging materials for batteries and specialty composites, the pin mixer’s versatility and efficiency are helping manufacturers meet increasingly stringent product and process requirements.

And with innovation still accelerating in carbon-based technologies, the ability to test, refine, and scale these processes through facilities like the FEECO Innovation Center will remain vital, ensuring producers can bring high-performance carbon materials from concept to commercial reality with confidence.