Engineered for Efficient Material Conditioning

At the heart of the DBBS is a powerful mechanical conditioning system. Hydraulic cylinders apply controlled, evenly distributed force to crush compacted material without compromising the integrity of the bag. This targeted action eliminates lumps, prevents bridging, and prepares the contents for consistent, trouble‑free emptying.

A standout feature is the liftable, rotating table. By allowing the operator to position the bag ergonomically and precisely, the DBBS ensures stable handling throughout the conditioning cycle. This not only improves efficiency but also reduces physical strain and enhances workplace safety.

Built for Versatility

The DBBS is compatible with all types of powders and can be integrated into a wide range of production environments – from chemicals and food processing to pharmaceuticals and specialty materials. It accommodates big bags of various sizes, supports loads up to 2000 kg, and adapts easily to non‑standard bag or pallet dimensions. With a recommended filling level of up to 70%, it offers flexibility without compromising performance.

Construction materials include stainless steel 1.4301 (304) and painted steel 1.0037 (1015) in RAL 5015, with custom colors available on request.

Key Benefits at a Glance

- Stable material flow

Ensures smooth, predictable discharge with no bridging or blockages. - Effective lump breakdown

High decompaction force with gentle, controlled action. - Big bag protection

Conditioning is precise and safe, preserving the bag’s structure. - Fully automated operation

Minimal operator involvement thanks to intelligent process control. - Maximum safety

Integrated safety systems protect both operators and equipment. - Flexible configuration

One station can handle multiple products and bag types.

Core Technologies That Drive Performance

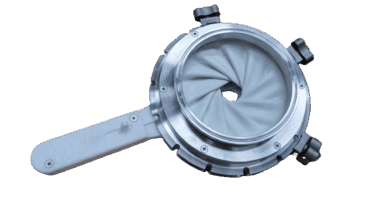

Side Massage System

A three‑zone conditioning system—upper, middle, and lower—applies up to 80 kN of pressing power exactly where it’s needed. Uniform force distribution ensures efficient loosening of compacted blocks while maintaining packaging integrity.

Scissor Lift with Rotating Table

The independently constructed scissor lift features a 90° indexed rotating table with up to five working positions. This design guarantees stable handling, accurate alignment, and repeatable conditioning cycles.

Industrial‑Grade Hydraulics

Built for continuous, high‑load operation, the hydraulic system uses double‑acting cylinders and a power unit rated up to 180 bar. The result is smooth, reliable movement and long‑term durability in demanding environments.

Safety at the Forefront

The DBBS incorporates comprehensive safety features, including light curtains, safety bumpers, and protective side panels. A dedicated service mode ensures maintenance can be performed safely. In fully automatic mode, the system minimizes operator exposure while maximizing protection.

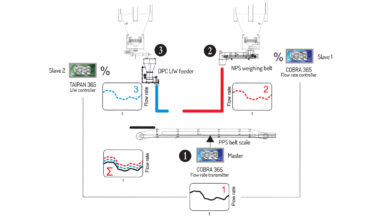

Intuitive Process Control

A user‑friendly HMI gives operators full access to automatic operation, preset recipes, and key process parameters. Fast configuration and easy bag replacement help keep workflows smooth and production continuous.