Yet selecting the ideal conveyor from the wide variety of options while under pressure to prioritize throughput, dust control, contamination prevention, ease of use, safety, and cost confounds even the most experienced process engineers, according to Dominick Fortuna, president of pneumatic vacuum conveying equipment manufacturer Volkmann USA, Bristol, PA (https://www.volkmannusa.com). Fortuna offers key considerations for evaluating conveying systems for up and in applications:

Conveyors Support Safety

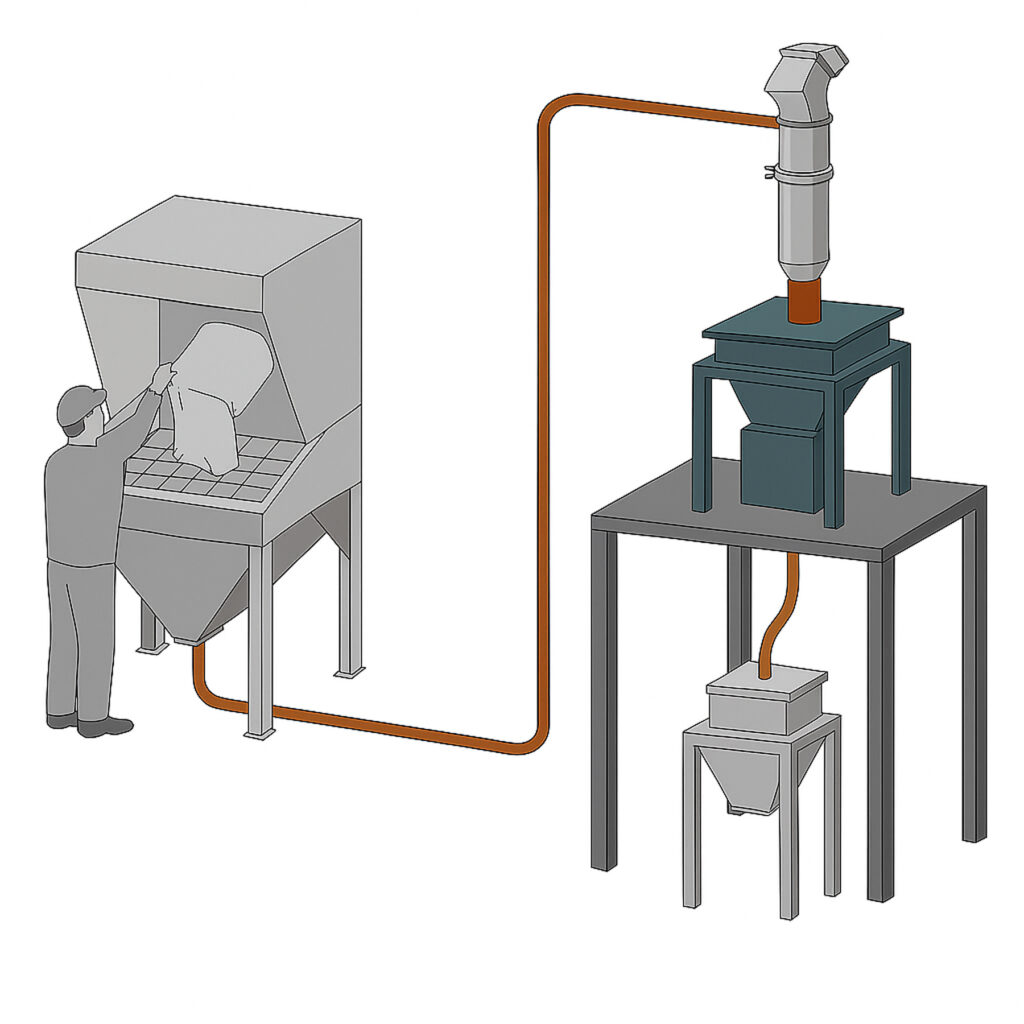

The most common conveying system in food, chemical, pharmaceutical, and other plants relies on people carrying 50-pound bags of material up stairs and ladders for dumping into a hopper or port. This creates a high risk of slips, trips, falls, and back injuries, and often exposes workers to a cloud of dust, splashing, and/or hazardous vapor exposure. Automating this manual method with a pneumatic vacuum conveyor eliminates the numerous safety concerns for a vastly safer, cleaner, and more efficient work environment.

Conveyors Protect Quality

Many materials are highly sensitive to contact with air or moisture and even brief exposure during the up and in transfer process may compromise their material properties. Ascorbic acid (vitamin C), pectin, corn starch, whey protein, and lecithin are some of the materials that deteriorate due to this exposure. Conveyors that contain the materials within a sealed, dust-tight system from storage up and in to the destination prevent this contamination risk and safeguard the purity for consistent product quality.

Conveyors Deliver ROI

In many up and in applications, several different types of conveyors such as pneumatic vacuum conveyors, screw conveyors, and tubular drag conveyors could safely automate the process at an accessible initial cost. Considering the cost of a single workers’ compensation claim for a slip, trip, or fall averages $49,971.00 (National Safety Council), the cost of just one manual handling injury could easily exceed the investment needed to upgrade to an automated approach. When also considering the immediate improvements in efficiency, productivity, and quality, with the cost savings in labor, automating the material transfer process often delivers a return in a matter of months.

For more information, contact Volkmann, Inc., 1900 Frost Road Suite 102, Bristol, PA 19007; 609.265.0101; contact@volkmannusa.com; www.Volkmannusa.com.