Why Bend Design Matters

Every time air and material hit a bend, there’s a change in velocity, a shift in direction, and, let’s be honest, a little chaos. If the radius is too tight, particles slam into the outer wall like it’s rush hour traffic. That means more turbulence, more wear, and for some materials—think sugar crystals or delicate pellets—more breakage. Over time, it’s not just your bends taking a beating; it’s your product quality, too.

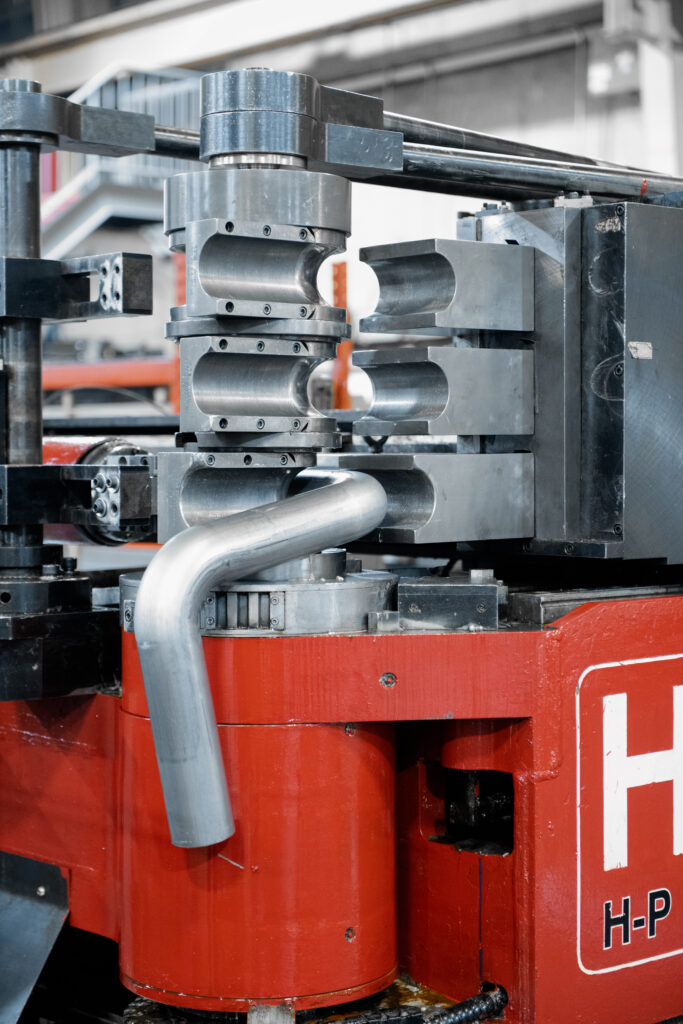

The Role of Radius, Angle, and Finish

Getting it right is all about balance. Larger radii help soften those impacts and reduce pressure drop, but you still have to work within the space you’ve got. Precision forming makes sure every bend matches the spec with no surprises and no “close enough. ” And a smooth internal finish? That’s your best friend for keeping material moving, avoiding hang-ups, and cutting down on contamination risks. For abrasive materials, the right combination of wall thickness, geometry, and material can be the difference between “set it and forget it” and “here we go again. ”

A Common Scenario

It’s not unusual to see plants battling recurring plugs or premature wear in bends. Often, the culprit is the same: inconsistent radii, rough surfaces, and geometry that isn’t optimized for the material. Replacing those problem bends with precisely formed components that have smooth interior finishes and consistent geometry can turn things around. The result is lower pressure drop, fewer blockages, and longer maintenance cycles.

The Takeaway

Bends aren’t just filler between straight runs. They’re a key player in your system’s efficiency. Taking the time to match bend design to your material and layout can save energy, cut downtime, and keep your product in top shape. In other words, give your bends a little more credit…they’ve been steering your system right all along.