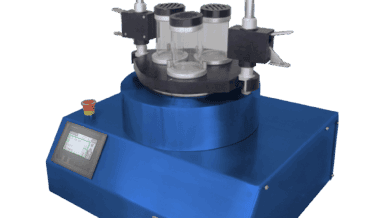

Elcan Industries developed the Hi Sifter, a high-energy sieving machine, to address these exact challenges. Designed for difficult-to-screen materials, the Hi Sifter applies intense vertical acceleration to the screen surface, allowing powders to pass efficiently through fine meshes without relying on ultrasonics. This high-energy motion keeps the mesh clear, reduces screen blinding, and supports consistent separations down to 10 microns in a single pass.

Unlike traditional vibratory or ultrasonic systems, the Hi Sifter uses a tensionless screen-mounting design that enables rapid screen changes in as little as 15 minutes. This minimizes downtime and gives operators the flexibility to run multiple size cuts or materials within the same production shift. The result is higher recovery rates, tighter particle-size distributions, and more predictable performance across R&D trials and full-scale production.

Elcan Industries works directly with customers to validate performance through real material testing. Whether processing stainless steel powders, titanium alloys, battery active materials, or other high-value powders, the Hi Sifter delivers repeatable results without compromising material integrity.

Watch the featured video to see how Elcan Industries applies high-energy sieving to solve real-world screening challenges and why manufacturers rely on the Hi Sifter when precision sieving matters most.