This assumption did not originate from theoretical limits. It developed from practical experience with conventional vibratory and ultrasonic screening equipment that struggles to process fine powders without persistent screen blinding.

Why air classification became the default

When traditional screening systems cannot maintain consistent throughput at fine mesh sizes, engineers often turn to air classification as the next logical step. In many facilities, this has become standard practice.

However, in a large number of applications, the limitation is not the material itself. It is the screening method.

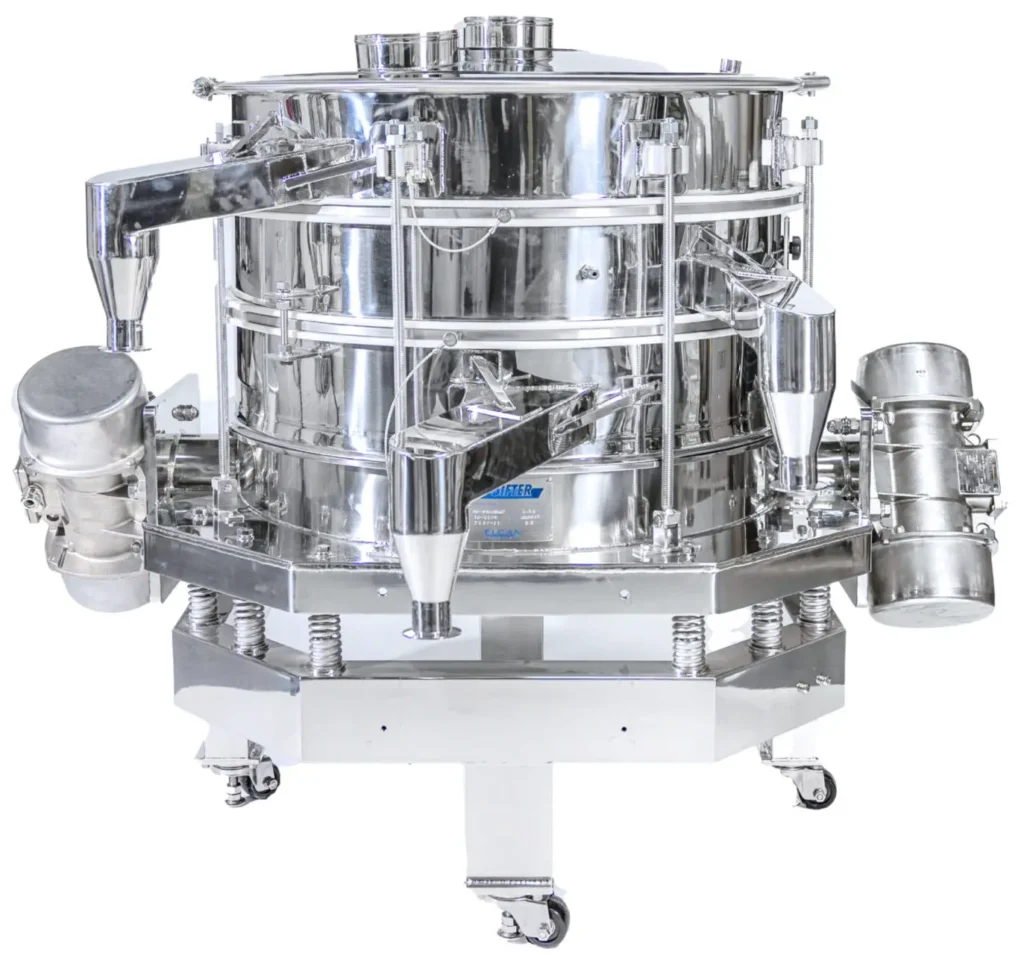

See the process here:

A different approach to fine screening

The Hi-Sifter high-energy sieving machine developed by Elcan Industries can screen powders down to 10µm and, in certain applications, as fine as 5µm, without ultrasonics and without requiring air classification.

The distinction lies in the motion profile and vertical amplitude. Unlike conventional vibratory systems, the high-energy vertical movement keeps the powder in continuous motion across a tensionless mesh surface. This eliminates screen blinding and enables separation at the true target cut sizes without having to “cheat the hole” in order to make a separation (like the other screeners do).

Questioning the assumed limitation

Before defaulting to air classification, processors may benefit from evaluating whether the limitation is truly material-driven or if it is a function of the screening technology being used.

In many cases, fine separation below 44µm is achievable through high-energy sieving on the Hi-Sifter sieving machine alone, with improved throughput and yields above 98% compared to traditional screening methods.