Why Particle Size Matters in Battery Powders

In battery electrodes, particle size determines the surface area available for electrochemical reactions, directly affecting charge/discharge rates, conductivity, and cycle life. A narrow PSD ensures uniform packing density, improved energy density, and consistent performance. Conversely, oversized or irregular particles may lead to poor conductivity, higher resistance, and even safety risks during operation.

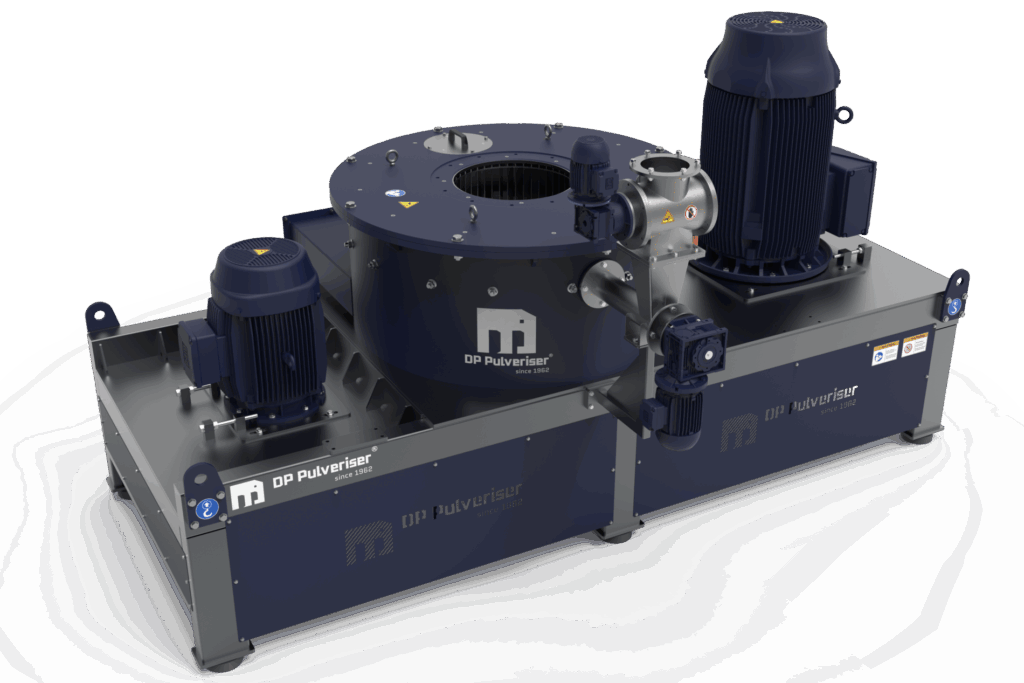

The Air Classifier Mill Advantage

Among various size reduction technologies, the Air Classifier Mill (ACM) has emerged as a reliable solution for processing battery materials. Unlike conventional grinding mills, ACMs combine grinding and classification in a single compact system. This integration allows continuous control of PSD with high precision, enabling manufacturers to consistently achieve the desired micron or sub-micron range.

Application Examples: Graphite and Carbon Black

- Graphite (Anode Material): Natural and synthetic graphite must be ground to a narrow PSD to optimize conductivity and ensure uniform electrode structure. Graphite particles that are too coarse hinder energy density, while overly fine particles increase reactivity and may compromise cycle life. The ACM’s ability to precisely control particle cut size makes it ideal for achieving this delicate balance. Additionally, wear-protected designs minimize contamination, which is critical since even trace metallic impurities can shorten battery life or cause safety issues.

- Carbon Black (Conductive Additive): Carbon black is widely used in small percentages to improve the conductivity of both cathode and anode formulations. Its ultrafine nature requires careful handling to prevent agglomeration. ACMs provide the fine grinding necessary to break down clusters, while the integrated classifier ensures consistent, dust-free powders suitable for blending into battery slurries.

Beyond these, ACMs are also applied for processing cathode materials such as LFP and NMC, where precise PSD directly impacts charge/discharge efficiency.

Supporting Sustainable Growth in Energy Storage

The push for greener mobility and renewable integration means battery manufacturers must scale production while maintaining strict quality standards. Dry processing with ACMs offers an energy-efficient, scalable, and contamination-free approach to producing high-performance powders. This not only improves battery performance but also supports sustainable manufacturing practices by reducing chemical processing steps.