The two main goals of soil sample analytics are to manage the nutrient of soils and to monitor potential contaminations:

1) Nutrient Management: Soil analysis helps in determining the levels of essential nutrients such as nitrogen, phosphorus, potassium, and magnesium. These nutrients are vital for plant growth and development. By knowing the nutrient status of the soil, farmers can apply the right amount of fertilizers to meet the specific needs of their crops, preventing over-fertilization and nutrient runoff.

2) Contaminant Monitoring: Soil analysis includes testing for micronutrients and heavy metals such as boron, manganese, selenium, aluminum, cadmium, and lead. Monitoring these elements is important for ensuring soil safety and preventing contamination of the food chain. Heavy metals can be harmful to plants, animals and humans, so their levels need to be observed carefully.

The central issue: Stones!

Typically, each solid sample must be homogenized and ground before analysis since thorough homogenization is essential for obtaining reliable, reproducible results. Various mills are suitable for homogenizing soil samples, such as jaw crushers and ball mills. Even though these mills can crush the entire sample, including soil agglomerates and stones, it is essential to separate these components from the soil before homogenization for several reasons. First, stones can distort analytical results by diluting the sample and affecting the measurement of key parameters, such as pH, nutrient levels, and organic matter content.

Removing stones ensures that the analysis accurately reflects the soil’s true composition. Additionally, the sample becomes more uniform, which helps obtain consistent and reliable data. Stones can also damage the laboratory equipment used for analysis. Removing them minimizes the risk of equipment damage, ensuring the longevity and accuracy of analytical instruments. In summary, separating stones from soil before analysis is essential for ensuring accurate, consistent, and reliable results, protecting laboratory equipment, and improving soil management practices. But this task turns out to be not that easy – until now!

The fastest and easiest way to separate stones from soil samples: Retsch Sieve Shaker AS 200 control

The AS 200 control is a vibratory sieve shaker designed for precise and reproducible sieving results. It features a microprocessor-controlled measuring and control unit that allows for the digital setting, displaying, and monitoring of all sieving parameters. Additionally, it can store up to 99 standard operating procedures (SOPs) for routine analyses. The machine is not only suitable for separating stones from granular soil samples but also capable of breaking down agglomerates of stones and soil without crushing the stones themselves, allowing for the easy and reproducible separation of particles larger than 2 mm.

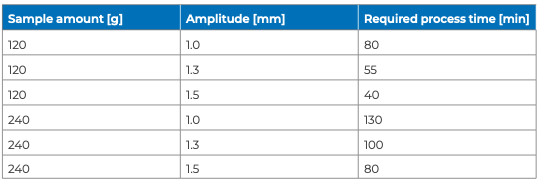

For instance, a 120 g soil sample with agglomerates no larger than 15 mm was placed on a 200 x 25 mm sieve with 2 mm round holes. Three stainless steel balls (zirconium oxide is also suitable) of 15 mm size were used on the sieve to facilitate the deagglomeration process. Trials were performed in three repetitions to determine the required time to break the agglomerates and separate the soil from the stone content. Different amplitudes were tested, as well as double sample amounts. The results are displayed in Table 1.

To protect the lid of the sieving machine from the bouncing balls and to reduce noise, an intermediate sieve pan (height 25 mm) was placed above the sieve. This setup also allows for parallel processing, as another 2 mm round-hole sieve can be placed on the intermediate pan with another soil sample. The AS 200 control can accommodate a maximum of 9 samples when intermediate sieve pans are used to stack the sieves. Larger initial soil/stone agglomerates of 15 mm were pre-broken manually or using the Retsch benchtop Jaw Crusher BB 50 with a gap width of 10 mm. The resulting agglomerate pieces were perfectly prepared for the AS 200 control method, requiring only a few seconds for a 120 g sample.

Right: Soil without stones

Conclusion

The combination of the Jaw Crusher BB 50 and the Vibratory Sieve Shaker AS 200 control offers an unparalleled solution for separating stones from soil samples. This method allows for the processing of large sample pieces and up to nine samples in one batch. Depending on the soil composition and the required sample amount, the process time is expected to be approximately two hours at most. This innovative procedure not only saves time in the lab but also ensures the most accurate analytical results for soil samples!