Yet, ask any process engineer or factory manager, and you’ll likely hear that these vessels come with their own set of headaches.

The Big Three Silo and Hopper Challenges

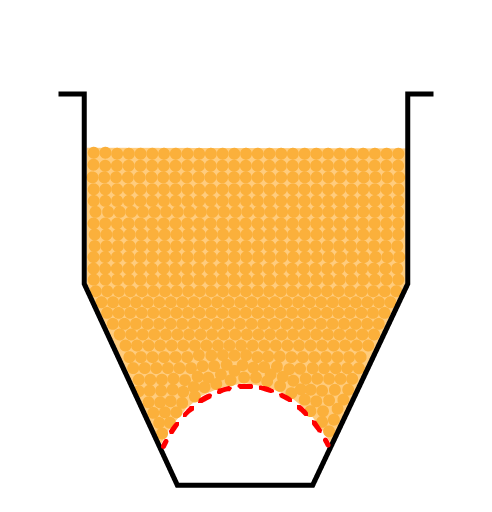

1. Flow Blockages: Arching & Ratholing

Perhaps the most frustrating issue with silos and hoppers is inconsistent flow caused by bridging (arching) or ratholing. Material either clumps and blocks the entire outlet or forms a narrow central tunnel that leaves product clinging to the walls. This can reduce effective capacity by up to 90% and cause erratic, unreliable feed to downstream processes.

Since traditional hoppers are made from stainless steel, visibility is zero. Operators often don’t even realize there’s a blockage until the production line grinds to a halt. The usual fix? Banging the side of the steel hopper with a mallet, risking damage, worker injury, or even triggering dust ignition.

2. Leaks, Dust & Hygiene Risks

Another critical challenge is maintaining clean, sealed transitions between vessels and downstream equipment. Conventional hose clamps often degrade under pressure or vibration, leading to leaks, contamination, and hazardous dust clouds. For industries under strict hygiene or ATEX compliance, this poses both operational and regulatory risk.

3. Maintenance & Downtime

Every unplanned stoppage translates to lost productivity—and in high-throughput plants, this can cost thousands per hour. Add in the labour required for difficult-to-access cleaning, replacing worn components, and reinstallation, and suddenly the maintenance overhead becomes a serious OPEX burden.

Flow interruptions, hygiene hazards, dust leakage, and unexpected downtime are all too familiar to any hopper user. But there is a smarter, cleaner, and safer way forward—and it starts with a flexible, snap-fit solution from BFM®.

BFM® is The Gold Standard in Flexible Connections

BFM® fittings have quickly become the connector of choice at the base of silos and hoppers across the globe.

Why? Because they eliminate the weaknesses of traditional pipe-to-pipe transitions. The BLUEBAND™ flexible connector system’s patented snap-fit design creates a super strong, 100% sealed, internally seated connection—without the need for clamps or screws.

Key BFM® Advantages:

- Visible, Reliable Seal: No room for leaks, strong and safe if there is an unexpected blockage.

- Tool-free Installation & Maintenance: Snap in, snap out—in seconds.

- FDA-Compliant, Anti-static Materials: Safe for food, pharma, and explosive dust environments.

- Durability: BFM® connectors last longer than traditional silicone-based options, reducing changeout frequency.

Going Beyond the Basics: Tapered Connectors & Hopper Alternatives

One of BFM®’s most innovative offerings are tapered connector options. Essentially these are BFM® flexible connectors with different diameters at each end, making them ideal where pipe sizes differ, but they are also being used by companies all over the world as an alternative to smaller-volume steel hoppers.

In a traditional steel hopper, seeing and addressing blockages is a matter of guesswork. However, by using BFM®’s tapered connectors made from transparent Seeflex material, flexible hoppers provide clear visibility of issues like bridging. They also allow operators to manually manipulate the hopper walls, helping to restore product flow quickly and efficiently.

Because these tapered connectors also use the BFM® fitting snap-fit system, access for cleaning is fast and easy – usually taking less than 30 seconds to remove.

Real-World Proof: Better Monitoring, Faster Cleaning

A recent case study with a Japanese nutrition manufacturer showed how switching from steel hoppers to BFM® fittings dramatically improved cleaning turnaround and product quality assurance.

The transparency of Seeflex 040E allowed staff to detect blockages or quality issues in real-time.

An additional benefit was the anti-static properties of the Seeflex material significantly reduced powder adherence to the hopper walls, minimizing disruptions caused by clogs. Any blockages that do occur can now be easily remedied.

The easy access provided by the snap-fit connection has also reduced cleaning downtime significantly.

A New Era: The BFM® Venting Surge Hopper

Intermediary hoppers – often called surge hoppers – are commonly used above rotary valves and similar flow-metering equipment. As with all hoppers, one of the key challenges in preventing bridging is ensuring sufficient air flow. Displaced air needs to be vented out of the hopper effectively to ensure consistent product flow.

Once again, these are nearly always made from stainless steel, which presents the same problems regarding visibility and access.

BFM® worked closely in partnership with rotary valve manufacturers to produce a tailored solution for these applications: the Venting Surge Hopper.

This innovative, transparent, flexible hopper includes an internal partition that separates product from air, and it simply snap fits into a corresponding partitioned lower spigot.

As powder flows down one side, displaced air exits through the other, helping to equalise pressure and encourage material flow.

What Makes It Game-Changing?

Transparent Walls: Made from Seeflex 040E urethane, the hopper allows full visibility of the product flow.

“See and Free” Blockages: If you spot a bridge forming, a simple hand massage through the wall can relieve it—no hammer needed.

Easy Maintenance: Snap-fit spigots at top and bottom make removal and cleaning effortless.

As one engineer put it: “With steel hoppers, you bang and hope. With the BFM® Venting Surge Hopper, you can see what’s happening—and act accordingly.”

Smarter Bulk Flow With BFM®

For engineers and plant managers, silos and hoppers will always be a backbone of production. But they don’t have to be a bottleneck.

BFM® fittings can help provide effective answers to age-old problems: blocked flow, dust leaks, hygiene risks, and costly downtime. Whether it’s a snap-fit connector, a tapered mini-hopper, or a cutting-edge Venting Surge Hopper, the BFM® system delivers cleaner, faster, safer results.

Ready to rethink your bulk transfer points?