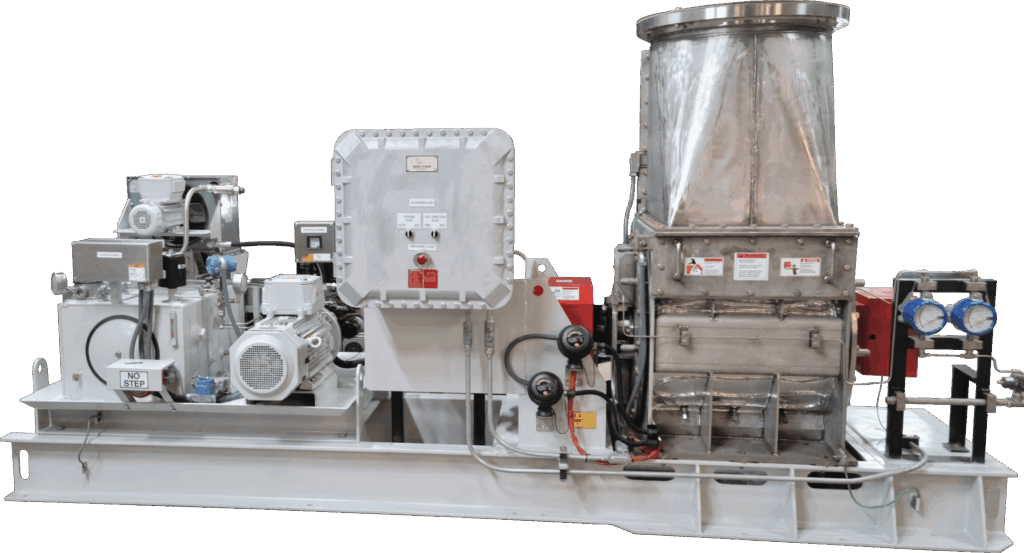

At their core, rotary airlocks regulate the flow of bulk solids—wood chips, grains, biomass, bark, minerals, powders—while preserving an airtight seal. This seal is not incidental but essential: it allows material to be introduced into either high- or low-pressure conveying lines without undermining the balance of the system. By preventing unwanted air leakage, the airlock ensures both the integrity of the pneumatic circuit and the efficiency of the overall process.

In this sense, rotary airlocks are less a matter of convenience than of necessity. They embody the principle that industrial systems function reliably only when pressure, flow, and containment are carefully managed at every junction.

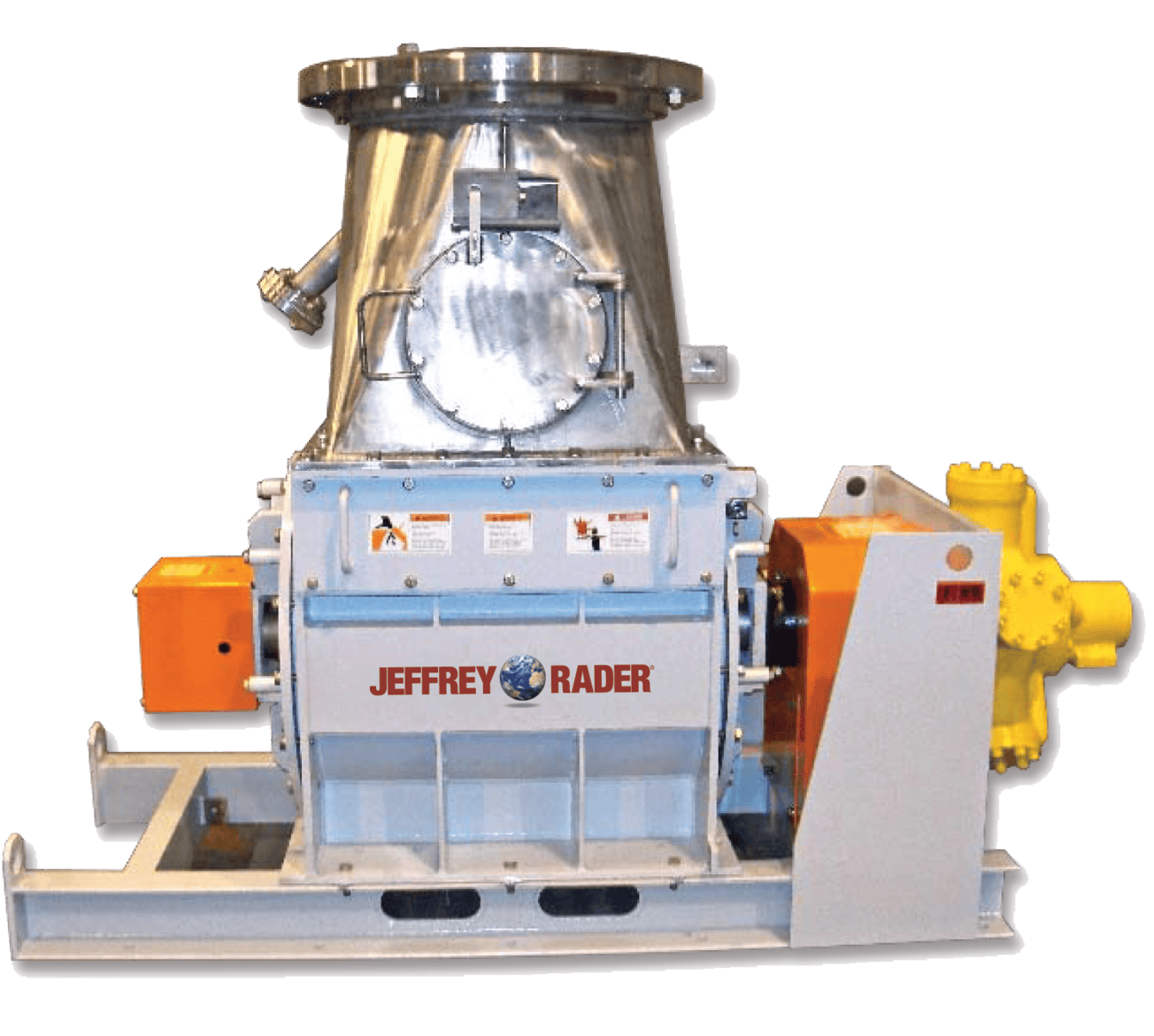

A specialized class of rotary airlock feeders—the EDK Rotary Feeders/Delumpers—has been developed to address demanding process conditions where precision and durability are essential. These units are designed for heavy-duty service, capable of maintaining highly controlled rotational speeds that ensure accurate volumetric feeding. Their application is especially critical in handling polypropylene and polyethylene resins under elevated temperatures and pressures, conditions where consistent material flow is paramount. In addition to metering, the integrated delumping capability enables the equipment to break down oversized agglomerates into smaller, manageable pieces, preserving process stability and preventing downstream blockages.

Design and Functionality

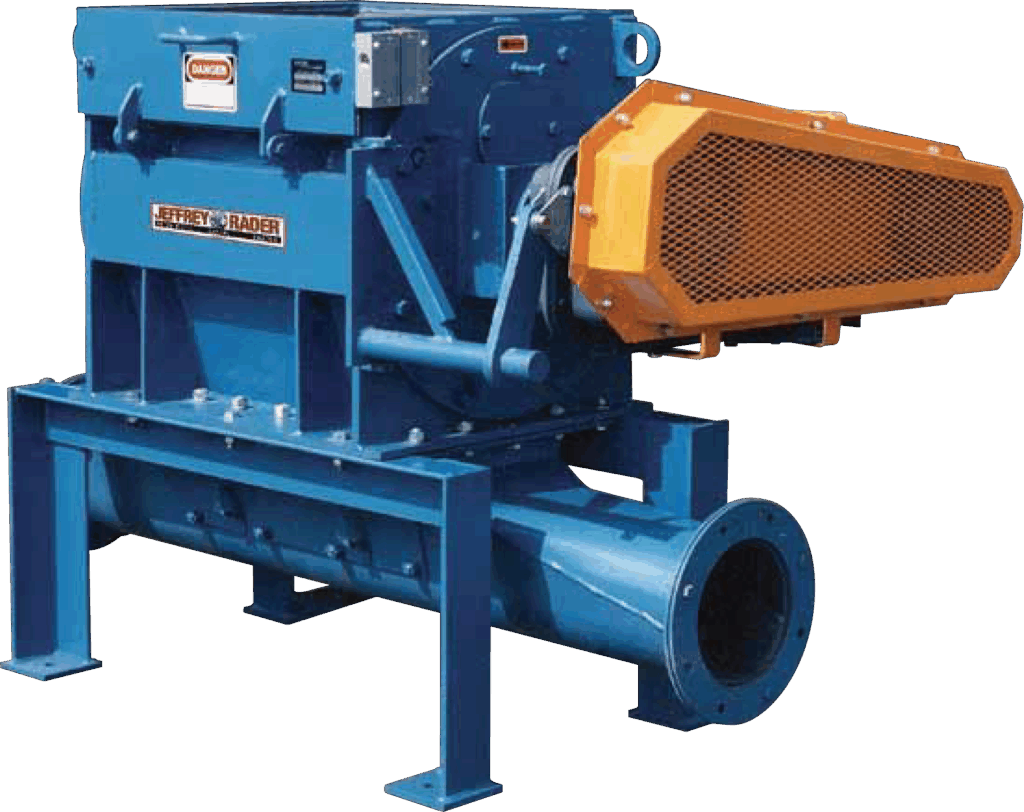

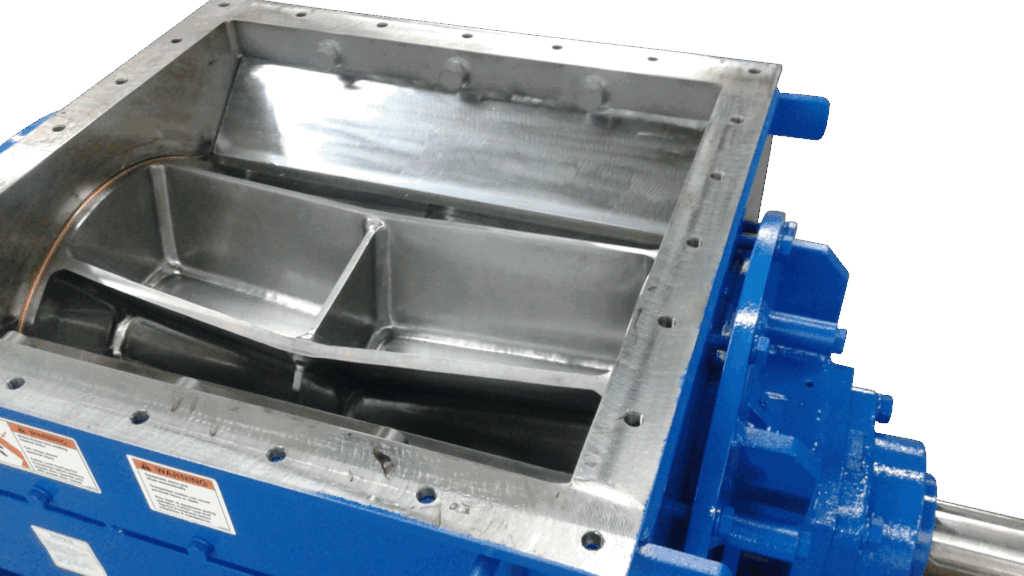

At its core, a rotary airlock feeder is a pressure-sealed housing containing a rotating vane assembly. Material entering through the top flange settles into pockets formed by the rotor blades. As the rotor turns, the filled pocket descends, discharges by gravity at the base, and cycles back to accept more material.

The design’s importance lies in maintaining system pressure while regulating flow. Reinforced rotors, heavy end plates, and durable drive shafts provide mechanical strength. Corrosion- and wear-resistant materials—stainless steel, chrome finishes, or ceramic liners—extend service life. Leakage is controlled by brass seal rings and packing glands, reducing air loss and preserving equipment integrity.

To ensure precise metering, a top knife trims excess material at the inlet. Optional bottom knives and wear bars are employed in abrasive or high-volume applications, cutting away buildup and preventing mechanical damage. Together, these features illustrate how rotary feeders balance durability, accuracy, and efficiency in demanding industrial environments.

Advantages

Rotary airlock feeders offer several key advantages for industrial operations:

- Pressure Integrity – They allow for efficient transfer of materials into pressurized pneumatic systems with minimal air loss.

- Continuous Duty Service – Built for durability, these feeders are capable of operating around the clock in demanding environments.

- Flexibility – A wide range of sizes, from small models to heavy-duty units, are available to match specific system requirements.

- Cost Savings – Rebuilt and OEM-standard feeders can be reconditioned to extend life and reduce operational costs.

- Customizable Options – From anti-dusting baffles to speed sensors and special coatings, feeders can be adapted to meet unique operating conditions.

Applications

Rotary airlock feeders are commonly used in industries such as:

- Biomass and energy production – feeding wood chips, pellets, or other fuels into boiler systems.

- Cement and minerals – handling abrasive powders under high pressure.

- Food and agriculture – conveying grains, flour, or feed with strict cleanliness standards.

- Chemical processing – controlling the flow of powders or granulates into pressurized reactors.

Their adaptability across industries makes them indispensable in modern material handling operations.

Conclusion

Rotary airlock feeders are often overlooked as simple mechanical devices, yet their role is central to the safe and efficient performance of pneumatic conveying and boiler feed systems. These feeders provide the essential function of maintaining a pressure seal while controlling the rate of material transfer, preventing system losses and safeguarding overall process stability. Their robust construction and ability to adapt through various design features enable them to operate reliably under demanding industrial conditions.

From an engineering standpoint, high-quality rotary airlock feeders are not optional accessories but critical components for system integrity. Without them, issues such as air leakage, material backflow, or inconsistent feed rates can compromise safety, efficiency, and long-term equipment performance. Recognizing their importance is therefore less about cost justification and more about understanding the fundamental mechanics that sustain industrial bulk material handling.