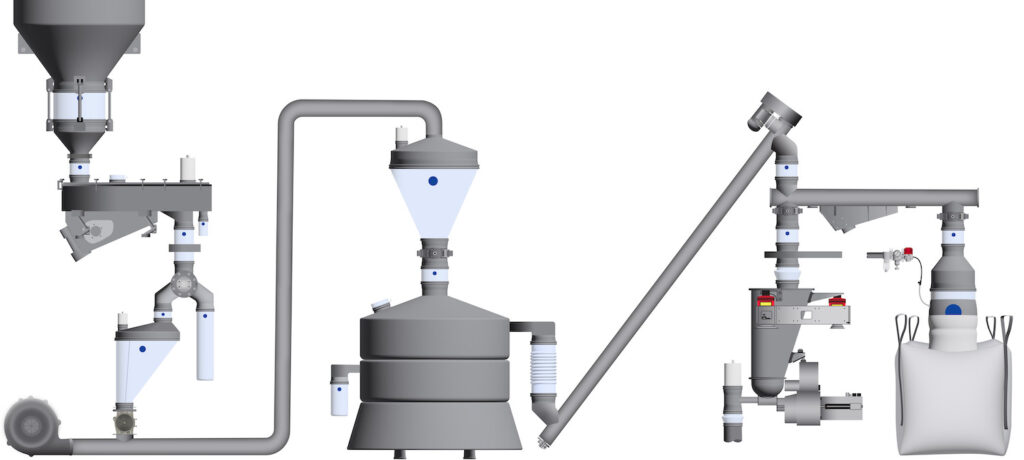

Every bulk processing plant is a complex ecosystem of equipment—silos, sifters, cyclones, feeders, blenders, dryers, and more—all working together to move powders or granules through each stage of production. Each piece of machinery comes with its own vibration, pressure, and hygiene challenges, and finding flexible connectors that perform reliably across them all can be a major headache.

Traditional hose-clamp-style connectors might work for a while in one spot, only to fail in another—leaking dust, tearing under movement, or compromising product safety. These weak links create downtime, contamination risks, and unnecessary maintenance.

That’s why leading manufacturers worldwide—from Nestlé to BASF—have switched to the BFM® snap-fit flexible connector system. Engineered for versatility and built for performance, BFM® fittings deliver one standardized connection solution that works seamlessly from silos to bag houses and everything in between. With tool-free installation, superior sealing, and a wide range of material options, they provide the reliability and efficiency every modern plant needs to stay clean, safe, and productive.

Smarter Connections, Safer Operations

The BFM® system consists of two stainless-steel spigot adaptors welded to adjoining equipment, with a flexible connector sleeve that simply snaps into place—no clamps, tools, or gaskets required.

Despite its simplicity, it delivers serious performance: it handles both positive and negative pressures, maintains 100% dust-tight containment, and resists vibration and movement between machines.

For operations where uptime, hygiene, and containment are critical, this innovation is a game-changer.

One Connector, Endless Applications

BFM® fittings can be installed virtually anywhere on the plant floor:

- Sifters and Sieves: Traditional connectors fail under vibration, but BFM® snap-fits and stays secure, preventing leaks and reducing premature wear.

- Blanking Caps and Blanking Bins also make inspection and collection of sifter overs simple. FM1 Breather Bags allow air-flow without dust leakage.

- Silos and Hoppers: BFM® connectors provide a strong, secure transition to downstream processes. Tapered BFM® connectors and Venting Surge Hoppers made from transparent Seeflex can also act as intermediary hoppers, helping detect and resolve bridging or blockages.

- Rotary Valves and Feeders: Maintain airtight seals under vacuum or pressure for thousands of cycles.

- Cyclones and Baghouses: Tool-free, leak-proof changeovers keep dust collection systems efficient. BFM®’s inflatable Bulk Bag Loaders secure bag necks, preventing contamination and product loss.

- Metal Detectors and Inspection Stations: Clear Seeflex sleeves allow visual inspection, and live sampling can be done using a Quick Access Port—without interrupting production.

- Dryers and Atomizers: High-temperature-resistant materials and 100% dust-tight seals handle fine powders from hot processes like spray-drying.

- Mixers and Blenders: Frequent line changes and clean-in-place operations are faster and safer with BFM®’s snap-fit, tool-free installation.

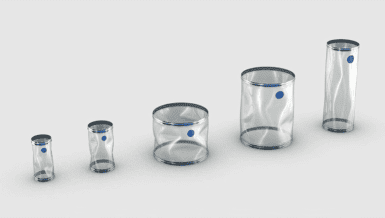

Materials for Every Process

BFM® connector materials are engineered to perform in diverse industrial environments – including:

- Seeflex 040E: Super-durable, crystal-clear polyurethane – the ultimate in versatility.

- Seeflex 040AS: Added anti-static protection for ATEX and IECEx zones.

- Seeflex 060ES: Reinforced especially for high-pressure applications.

- LM3: Woven Polypropylene ideal for lower temperatures and where some breathability is needed.

- Teflex Range: Options to handle harsh chemicals and extreme operating temperatures from -73°C to 300°C.

Additional accessories—Breather Bags, Blanking Caps, Blanking Bins, Support Rings, and protective Black-Out or Kevlar Covers—extend versatility and pressure resistance.

Compliance Built In

Safety and regulatory compliance are essential. BFM®’s most popular materials are FDA, EC, and 3A-approved, and certified for use in ATEX environments. Unlike hose clamps, the snap-fit system reduces static risks and potential ignition points. For industries like pharmaceuticals, food, and chemicals, BFM® fittings help ensure contamination control and audit-ready operations.

Modular Design Reduces Downtime

Unplanned downtime is expensive. BFM® connectors can often be replaced by hand in under 30 seconds—no tools or specialized training required.

Standardized sizes (50mm increments from 100–1650mm) simplify spare parts management and eliminate the installation errors common with cut-to-length hose sleeves.

Proven Results in the Field

With well over 10,000 installations worldwide, BFM® fittings consistently deliver measurable results. One major US chicken processor saved over 90% on cleaning costs alone with the faster fitting process speeding up their cleaning cycles, and a UK plaster manufacturer reported the BFM® connectors last over 50 times longer than their previous ones – a massive saving in terms of non-productive downtime.

Across all bulk manufacturing industries—from cement to nutraceuticals—the outcomes are the same: cleaner, safer, more efficient operations.

The Future of Flexible Connections

As plants increase automation and stricter safety standards, reliable components like BFM® connectors become essential. Their repeatable performance enables better process monitoring and consistency, whether in new plant builds or retrofits.

The BFM® fitting isn’t just a flexible connector—it’s a productivity enabler. Its versatility allows engineers to use one standardized solution across the entire plant, confident it will meet hygiene, safety, and performance standards.

From sifters to cyclones, it’s the smarter, safer choice for modern bulk processing.

For expert guidance on selecting the right connector for your plant, visit www.bfmfitting.com or contact your local distributor.