Scope of Supply:

- Equipment Delivery

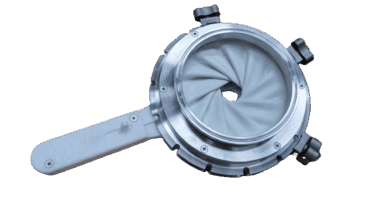

- The mechanical scope included:

- Receiving hopper

- Hammer gate valve

- Screw conveyors

- Silo

- Dosing screw

- Weighing arrangement for the receiving

- hopper

- Stairs and maintenance platforms

- Site Works

- Mechanical installation

- Commissioning support

In addition to equipment delivery, Laitex provided on-site mechanical installation and commissioning assistance, ensuring proper alignment, functional testing, and integration into Yara’s production process.

System Design for Sulphur Handling

Sulphur handling requires careful consideration of material properties, dust control, and explosion protection. The system was designed to provide:

- Controlled and consistent material flow

- Enclosed conveying to minimize dust emissions

- Protection against material losses and contamination

- Compliance with environmental and plant safety requirements

Laitex implemented enclosed screw conveying and dosing solutions to maintain operational reliability and minimize exposure of sulphur dust to the surrounding environment.

To meet client’s safety standards, the installation incorporates measures in accordance with ATEX requirements.

Integration of Process Know-How and Mechanical Engineering

The solution integrates process understanding with mechanical design to ensure durability and operational stability under plant-specific conditions. Equipment selection and layout were defined to match sulphur characteristics and the required handling capacity within the existing facility.

By combining equipment supply with installation and commissioning support, Laitex contributed to a controlled start-up phase and stable long-term operation.