A one-size-fits-all approach to dust collection won’t work in environments where material properties, process flow and production demands vary widely. The dust collection system must be tailored to the dust characteristics (e.g., particle size, abrasiveness, moisture content, combustibility, agglomeration) as well as the equipment layout and operational needs.

These six design best practices will ensure your dust collection system delivers safe, efficient and compliant performance in even the most demanding mixing and blending environments.

1. Capture Dust at the Source

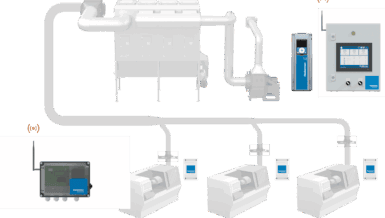

The most effective way to control dust in mixing and blending operations is to capture it at the point of release and direct it into a properly designed dust collection system. Effective source capture prevents particulate from propagating through the environment. This not only protects workers and equipment but also reduces the overall air volume that must be filtered, leading to a more efficient and cost-effective system.

In mixing and blending, dust is often generated during key process steps: loading dry ingredients into mixers, adding materials through access ports, transferring blended product or during discharges and cleanouts. Dust capture points should be located as close as possible to these sources, using ducts, hoods or enclosures designed to draw particulate-laden air directly into the filtration system.

2. Use Application-Specific Hood Design

Hood design plays a critical role in how effectively dust is captured and directed into the dust collection system. The right hood depends on the type of equipment, the location of dust release, and the physical space around the process.

- Enclosing hoods offer the best control by limiting airflow requirements and preventing dust escape. They’re ideal for high-dust operations or materials prone to becoming airborne.

- Slot or backdraft hoods work well for open-top mixers or material loading, pulling dust horizontally across the emission point.

- Canopy hoods are less effective since they rely on dust rising into the hood. They may help with light, diffuse dust, but shouldn’t be the primary solution.

- Close-capture options, like fume arms or articulating hoods, are great for manual tasks or mobile operations, allowing flexible, targeted dust collection right at the source.

Regardless of type, hoods should be positioned as close to the dust source as possible and designed to guide airflow smoothly into the ductwork.

3. Select the Right Dust Collector Type

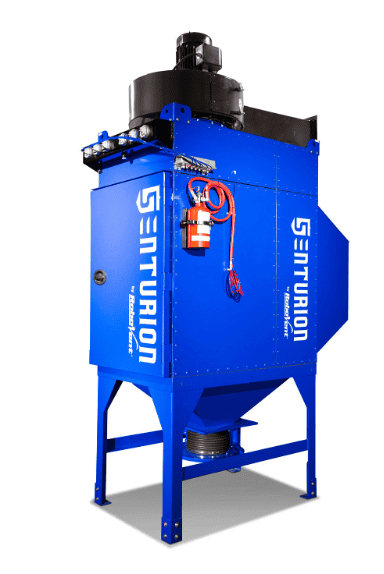

For most mixing and blending operations, cartridge dust collectors are the optimal choice. Their compact footprint, high filtration efficiency, and ability to handle fine, dry particulate make them well-suited for the dust profiles typical of powder processing environments. Cartridge collectors use pleated filter media, which provides a large surface area in a small space. This allows for efficient collection of dust generated during mixing of bulk materials, including ultrafine powders, hygroscopic (moisture-absorbing),

- Baghouse collectors are sometimes used for very large systems, but typically require more space, maintenance and energy.

- Wet scrubbers are sometimes recommended for highly combustible dusts or for sticky, hygroscopic, or high-moisture dusts that would clog dry filters.

- Cartridge collectors strike the right balance of performance, space efficiency and cost for most dry mixing applications.

4. Size the Dust Collector for Airflow and Filter Load

Proper sizing is critical to ensure effective capture and long-term system performance. Two key factors drive sizing: airflow (CFM) and air-to-cloth ratio.

- Airflow requirements depend on the number of capture points, hood design, and process dust levels. Each pickup point must have sufficient CFM to maintain the necessary capture velocity—typically 100-300 feet per minute at the hood. Capture velocity will depend on dust characteristics such as size and weight.

- Air-to-cloth ratio reflects how much air passes through each square foot of filter media. For fine powders, heavy dust loads and more challenging dust types (e.g., hygroscopic or agglomerating dust), a lower air-to-cloth ratio (e.g., 2:1 to 3:1) helps prevent filter overload and ensures efficient filtration.

5. Choose the Right Filter Media

Cartridge filters offer a wide range of media options and treatments to handle different dust types and hazard levels. Selecting the right filter media is essential for performance, safety and filter longevity. Key considerations when specifying cartridge filter media:

- Dust particle size: Standard cellulose-blend media works for larger, less hazardous particles. Use nanofiber media for ultrafine dusts to improve surface loading and cleaning. Depending on dust size and hazard level, a HEPA after-filter may be recommended.

- Moisture or stickiness: Choose PTFE-coated or synthetic spunbond filters to resist clogging and improve cleanability. For oily or hygroscopic materials (those that absorb moisture from the air) an oleophobic treatment can help shed moisture and reduce filter loading.

- Agglomerating dusts: Powders that tend to clump or stick together (such as starches or sugar blends) can quickly plug filter surfaces. Smooth-surfaced media like PTFE-coated spunbond polyester helps prevent dust buildup and supports more effective pulse cleaning.

- Combustible or conductive dusts: Use conductive or anti-static media in explosion-prone environments to prevent static charge buildup.

- Abrasive dust: Select heavy-duty media such as spunbond polyester to stand up to abrasive dust. A PTFE coating can reduce wear and extend filter life.

6. Address Fire and Explosion Risks

Many powders handled in mixing and blending operations are combustible, making dust collection a critical component of your facility’s fire and explosion safety strategy. The design of the collection system must account for dust deflagration hazards and comply with applicable NFPA standards.

Key design considerations include:

- Using conductive or anti-static filter media for explosive dusts

- Installing explosion vents, flameless venting or suppression systems on dust collectors

- Incorporating backdraft dampers or isolation valves to prevent propagation into the facility

- Locating collectors appropriately, with outdoor placement for high-risk materials when feasible

Putting it All Together

Dust control in mixing and blending operations requires a system engineered around your materials, processes, and risk profile. Dust characteristics like particle size, moisture content, and combustibility must inform every design decision—from hood placement to filter media selection. Cleanliness requirements, especially in food or pharmaceutical applications, add another layer of complexity.

To get it right, partner with a qualified dust collection system engineering partner that understands the nuances of bulk material processing. The right partner will help you build a dust collection system that ensures safety, regulatory compliance, and optimal performance from day one.