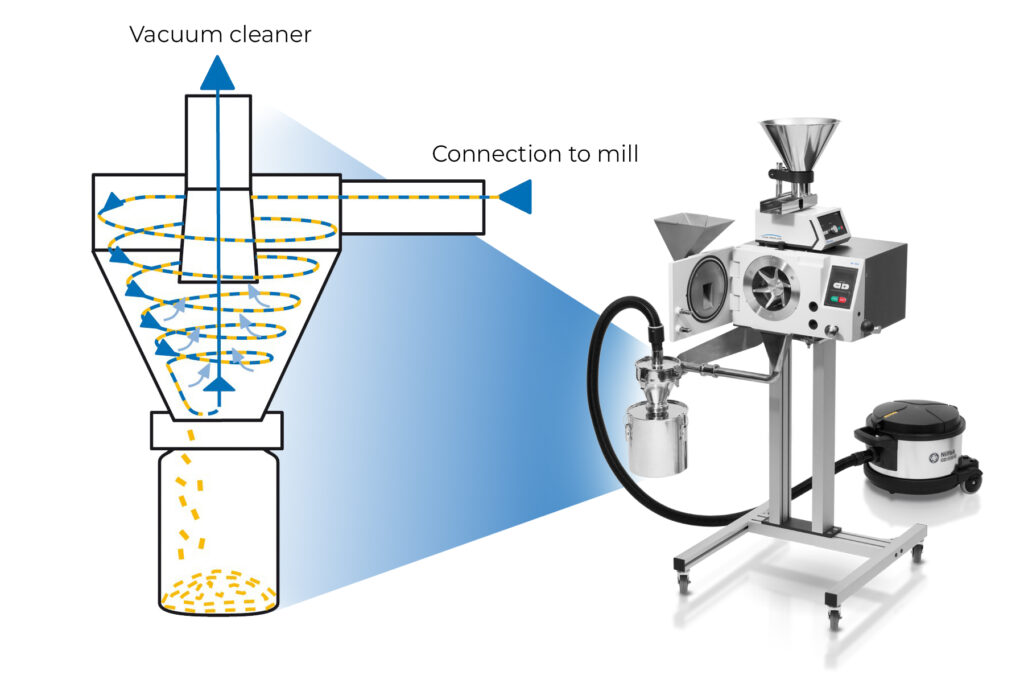

How does a cyclone work?

A cyclone separator is connected to the mill outlet, a vacuum system, and a collection receptacle. The vacuum draws the air-particle mixture from the grinding chamber into the cyclone, where it enters tangentially and begins to spiral. Centrifugal forces push the heavier particles outward, causing them to fall into the connected collection receptacle, while the cleaned air exits through the top. The functional principle is illustrated in Figure 1.

Reasons for using a cyclone separator

A cyclone separator ensures efficient transfer of sample material from the grinding chamber to the collection receptacle. This results in less dust emission and cleaner processes, which are reflected in the following practical advantages:

- Time and cost efficiency – Minimal cleaning effort and longer lifetime of the mill when operating in a low-dust environment.

- Maximum sample recovery – Less residue, ensuring even small sample quantities and fine particles can be reliably recovered. In air jet sieving machines, sample recovery is only possible with a cyclone separator, as without it, the sample is simply drawn into the vacuum cleaner.

- Safe working environment – Significantly reduced dust exposure creates a clean and healthy laboratory environment.

- Safe sample preparation of temperature-sensitive materials – Reduced heat buildup in the grinding chamber – important for milling setups using fine sieves or for samples that change their properties when exposed to heat.

- Flexibility in size and placement of collection receptacle – Cyclone-operated sample transport accommodates collection receptacle volumes from 250 ml glass containers up to 30 l receptacles with Retsch systems. The positioning of the receptacle is unrestricted, providing maximum adaptability.

The right cyclone for every application

The Retsch cyclone separator is available in numerous variants and can be flexibly adapted to different requirements.

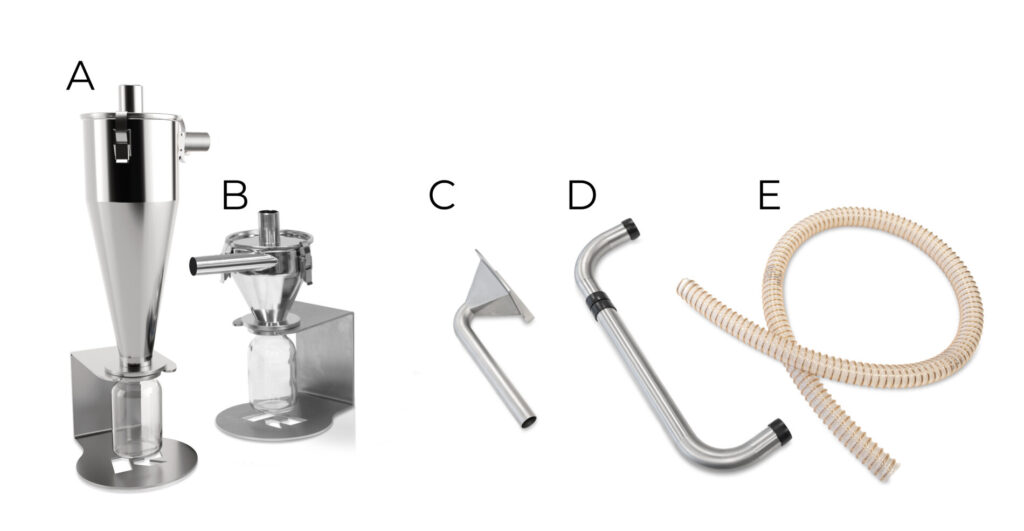

Flexible mounting options

Whether mounted directly on the machine frame, on a stable stand on the laboratory bench, or as an attachment with a hose connection to the collection container, there is a suitable solution for every laboratory environment. FDA-compliant hoses, rigid piping, or flexibly adjustable connections are all available, see Figure 2 right.

Different sizes and variants

Depending on the application, either the standard version or a high-efficiency variant for maximum recovery can be selected, see Figure 2 left. The Cutting Mill SM 50 and the Twister feature a particularly compact model, perfectly tailored to the sample flows generated in these mills.

Various materials

The cyclone is available in robust stainless steel or high-quality 316L steel for maximum corrosion resistance – making it ideal even for demanding applications in the food and pharmaceutical industries.

For which industries/applications are cyclone separators suitable?

The cyclone separator is suitable for a wide range of sample types and is used across various industries. It has proven particularly effective with dusty or slightly sticky materials that can adhere to mill surfaces. Limitations arise with very heavy or very light particles, or when too much sample is fed at once. Typical applications include the food and chemical industries, environmental analysis, mining, agriculture, materials research, the pharmaceutical industry, and recycling. Some examples are provided below.

Crushing of paint chips with the Rotor Mill ZM 300.

The use of the cyclone prevents the sample from being heated up during the grinding.

- 0.2 mm distance sieve, stainless steel

- 20,000 rpm

- Feed size: 20 mm

- Final fineness: 200 µm

- 250 g /3 min

Crushing of cannabis with the Cutting Mill SM 300 Food Grade.

The use of the cyclone unit minimizes material residues from sticky grinding materials on the mill and related surfaces, ensuring clean and efficient sample discharge.

- 4 mm bottom sieve 316l stainless steel

- 2,000 rpm

- Feed size: 60 mm

- Final fineness: 4 mm

- 40 kg / h

Crushing single pieces of roots in the Cutting Mill SM 50.

Thanks to the cyclone unit, sample discharge is maximised even with very small sample quantities.

- Standard Milling chamber with integrated cyclone

- 4 mm bottom sieve, stainless steel

- 4,000 rpm

- Feed size: 50 mm

- Final fineness 5 mm

- 1 piece/ 1 min

Crushing of bitumen in the Jaw Crusher BB 250

The cyclone prevents dust from escaping, contributing to a safe working environment and increasing the service life of both the bearings and the entire machine.

- breaking jaws of manganese steel

- wearing plates of hardened steel

- 2 mm gap size

- Feed size: 30 mm

- Final fineness 5 mm

- 1 kg / 5 min

Sieving of pharmaceutical powder in the Air Jet Sieving Machine AS 200 jet.

The cyclone enables reliable collection of the screened fraction.

- Test Sieve, ISO 3310/1, 200x50mm, 45µm, stainless steel, with compliance certificate

- Revolution speed 55 rpm

- 30 g /3 min

- 90 % < 45 µm

Crushing of biochar in the Hammer Mill HM 200

The cyclone allows a collection receptacle with a volume of 30 litres to be used, which makes it possible to process larger sample quantities.

- 2 mm bottom sieve, stainless steel

- 1 kg/ min

- Feed size: 10 mm

- Final fineness: 2 mm

Combination units for maximum efficiency

Preparing fine particles – for example, for analysis – from large pieces of hard and brittle material typically involves two separate steps using a jaw crusher followed by a disk mill. By integrating a cyclone separator, these processes can be combined into a single, automated operation. The cyclone enables direct material transport from the jaw crusher to the disk mill, allowing samples with feed particle sizes up to 60 mm to be ground in one pass to final fineness of up to 200 μm, as shown in Figure 3. This setup eliminates the need for manual sample transfer and additionally prevents dust from escaping the mills. It is especially effective when no sample splitting is required, providing a streamlined solution for applications in agriculture, cement production, mining, precious metal analysis, materials research, and environmental analysis.

Summary

Cyclone separators are a groundbreaking addition to laboratory milling and crushing processes, efficiently recovering sample material, preventing overheating of sensitive samples, and significantly improving workplace safety. They also enable the use of various, even larger, collection receptacles that are not possible with standard setups. Retsch cyclone separators are suitable for a wide range of applications and are available as accessories for numerous cutting and rotor mills, jaw crushers, and Retsch air jet sieving machines – they can also be retrofitted at any time. With the cyclone unit, it is also possible to combine a jaw crusher with a disk mill, allowing direct, dust-free sample transport between devices and efficient one-pass processing from large pieces to fine particles. Cyclone separators ensure maximum efficiency and sample integrity while minimizing dust emissions.