This setup can lead to inefficiencies, including a large footprint, multiple interfaces that complicate workflow, and increased reliance on manual interventions, not to mention higher overall and operating costs. The cumulative effect is a production environment that is prone to errors and delays.

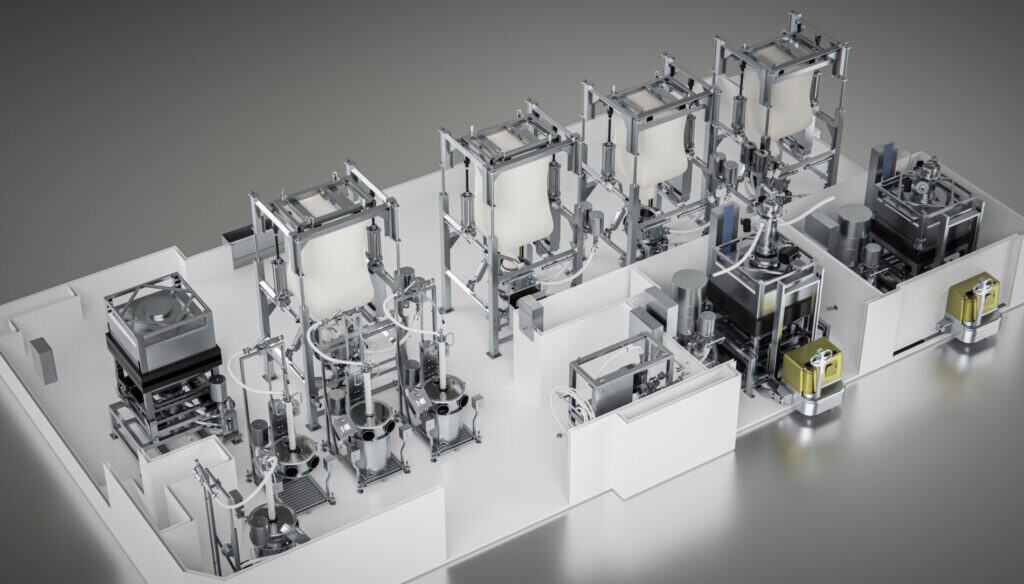

In contrast, the Dec Group concept integrates these steps into a fully connected operation. By providing closed systems and the PTS Powder Transfer System® as a central element for conveying, charging, and discharging, we streamline operations and reduce vulnerabilities.

A typical production layout using this integrated system approach showcases a seamless workflow that encompasses high-containment dispensing, granulation, blending, tablet pressing, and coating – all under one roof. The transformation from isolated areas to a cohesive workflow facilitates better collaboration and minimizes the risk of contamination or error.

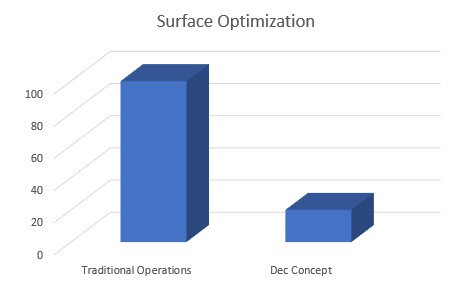

One of the most notable advantages of this fully automated system is the reduction in manual handling, which inherently lowers the risk factors associated with human intervention. Furthermore, the innovative design can reduce the pharma-rated surface area by as much as five times, translating into substantial savings in both capital and operational costs.

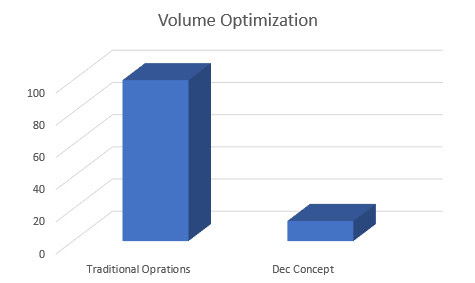

Perhaps even more impressive is the potential to decrease the overall volume of the production facility by up to eight times. This significant reduction allows for the implementation of a much smaller HVAC system, leading to considerable savings in energy consumption and maintenance costs. Additionally, the decreased footprint streamlines validation processes, further enhancing operational efficiency.

In conclusion, moving toward fully integrated OSD production systems not only improves efficiency but can also position manufacturers to better meet the demands of an evolving market, and eventually save money. By embracing closed systems and advanced automation, the Dec concept stands at the forefront of transforming traditional production methods into a model continuous manufacturing, efficiency, and sustainability.