Fundamentals of Efficient Dust Collection System Design

An efficient dust collection system starts with reducing the total air volume that must be moved to maintain safe, clean working conditions. Every cubic foot of air you don’t have to move or condition translates directly into lower energy costs and less wear on system components. Achieving this requires attention to physical capture, containment and airflow management. Here are some tips for efficient dust collection system design.

- Air Filtration and Recirculation: Filtration systems can dramatically reduce heating and cooling loads compared to systems that exhaust outdoors. An air filtration system, such as a cartridge dust collector, removes contaminants from the air before returning cleaned air to the facility. This keeps conditioned air in and reduces outdoor emissions.

- Source Capture: Capturing dust as close to the point of generation as possible is the single most effective way to reduce system demand. Well-designed hoods, enclosures and close-capture systems (e.g., fume arms, receiving hoods) can intercept dust before it disperses into the workspace, which means less total air volume is needed for collection. The closer and more effectively the capture point is placed, the greater the efficiency and the lower the ongoing energy costs.

- Barriers and Enclosures: Where processes cannot be fully enclosed and close-capture solutions are not effective or practical, physical containment—such as curtains, partitions and machine enclosures—limits the spread of dust and keeps it within a controlled capture zone.

- Pressure Zoning: Maintaining negative pressure in “dirty” areas and positive pressure in “clean” areas ensures that airflow consistently moves from clean zones toward dusty processes. This prevents contaminants from drifting into other parts of the facility, which reduces the need for extensive general ventilation. Well-planned zoning also makes local collection points more effective by keeping the surrounding air relatively dust-free.

- Optimized Ductwork: Duct layout plays a significant role in efficiency. Straight runs, smooth interiors and properly sized diameters minimize friction losses, while airtight connections prevent leaks that waste fan energy. Balanced branches ensure that each pickup point receives the designed airflow, preventing over-ventilation in some areas and under-ventilation in others.

By incorporating these design fundamentals, facilities set a lower baseline for airflow requirements. This makes it far easier for intelligent airflow control systems to deliver significant energy savings while still meeting safety and compliance targets.

Intelligent Airflow Control Systems: The Future of Smart Industrial Filtration

While good design reduces the baseline airflow a system requires, intelligent airflow control takes efficiency to the next level by adapting operation to real-time conditions. Instead of running a dust collection system at a constant speed as if every pickup point is active, intelligent controls sense where extraction is needed and adjust accordingly. This ensures air is only moved when and where it’s required, reducing wasted energy and wear without sacrificing safety or performance.

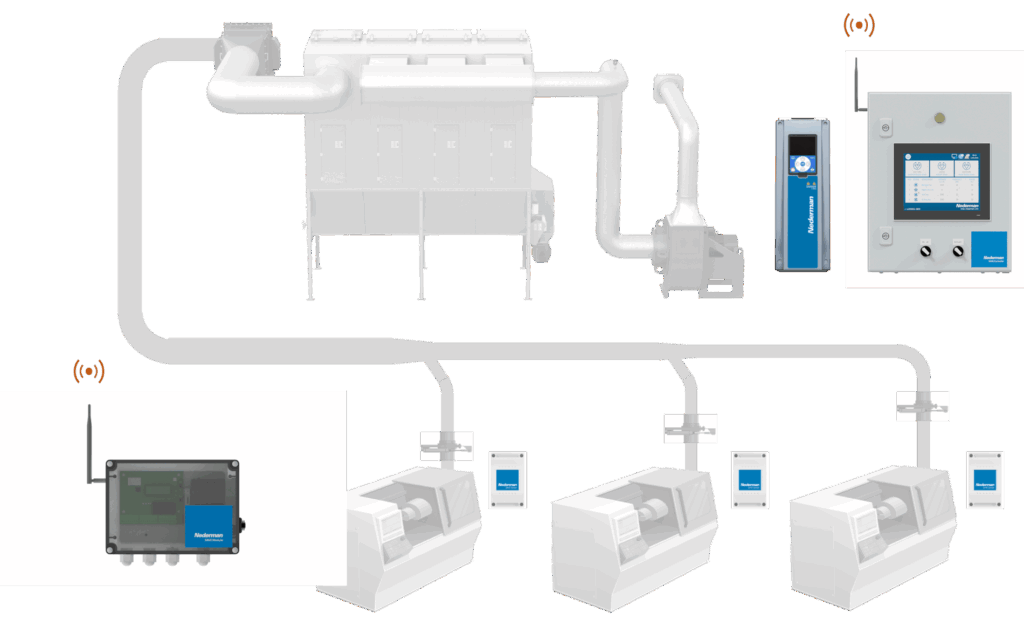

An intelligent airflow control system typically includes:

- Sensors that detect machine operation, airflow, static pressure or filter loading, providing real-time feedback on system demand.

- Automated dampers or blast gates that open and close at each pickup point, directing airflow only to active sources.

- Variable frequency drives (VFDs) on fans that modulate motor speed to maintain the required capture and transport velocities at the lowest possible energy input.

- On-demand filter cleaning that pulses only when differential pressure indicates it’s necessary, reducing compressed-air use and extending filter life.

- Monitoring and control software that coordinates these components, logs performance data and alerts maintenance teams to developing issues.

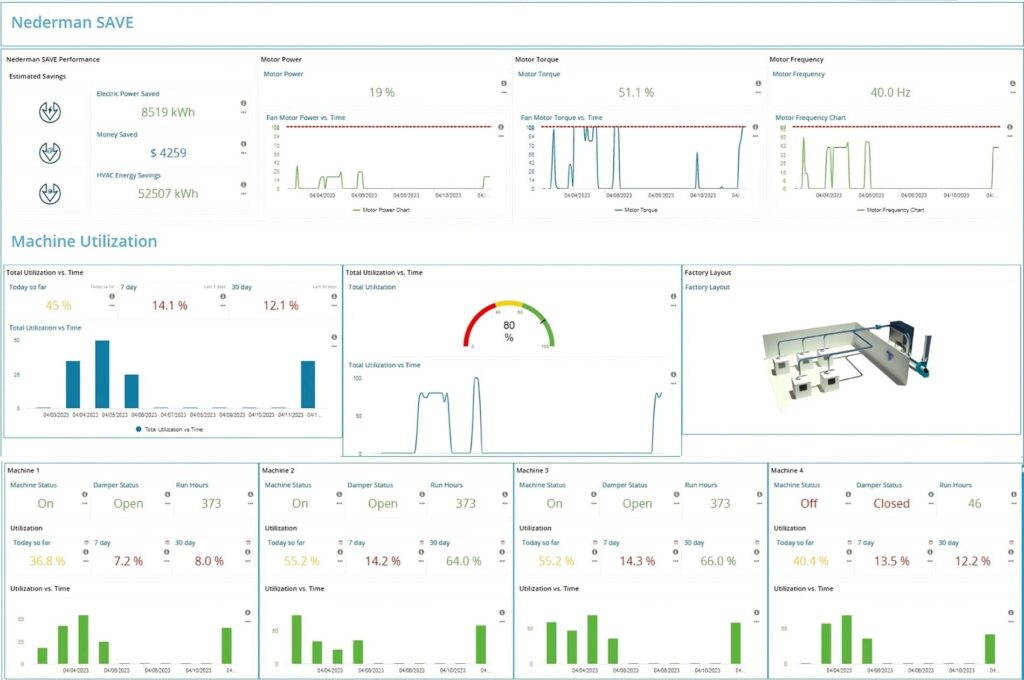

By integrating these elements, intelligent systems can maintain compliant airflow even as production cycles change throughout the day. While results vary by facility and process, plants with high variability in equipment use often see significant reductions in electricity and compressed-air consumption, along with quieter operation and longer component life.

Design Considerations for Intelligent Airflow Control

For intelligent airflow control to deliver consistent results, it must be planned and integrated thoughtfully into the overall dust collection system.

- Maintain Minimum Capture and Transport Velocities: The system must never allow airflow to drop below the levels required to capture dust at the source and keep it moving through the ductwork. Controls should include programmed minimum setpoints, and these should be verified during commissioning under different production scenarios to ensure safe, compliant performance.

- Integration with Existing Systems: Controls should work in harmony with facility ventilation, heating, and cooling to maintain stable pressure zones. Poor coordination can undermine dust capture or cause unwanted airflow patterns between clean and dirty areas.

- Safety and Compliance Alignment: Intelligent controls must operate within the constraints of applicable safety codes, particularly for combustible dust. This includes ensuring that any required explosion isolation, venting, or spark/ember detection operates effectively under all control states.

- Ongoing Maintenance and Calibration: Automated dampers, sensors, and VFDs require periodic checks to ensure accuracy and responsiveness. A preventive maintenance plan should include sensor cleaning, calibration and logic testing to keep the system operating as designed.

- Leveraging System Data: The performance data gathered by intelligent controls can be a powerful management tool. Tracking trends in airflow, static pressure and energy use can help identify inefficiencies and optimize production scheduling.

By focusing on these design and operational factors, facilities can ensure that intelligent airflow control not only reduces energy use but also maintains long-term reliability and compliance.

Designing for Long-Term Performance

Industrial dust collection doesn’t have to be an energy burden. By combining strong design fundamentals—source capture, zoning, containment, efficient ducting, and safe recirculation—with intelligent airflow control, facilities can maintain clean, compliant air while using significantly less energy. Systems that adjust airflow to actual production demand, such as those built on principles used in the Nederman SAVE system, show how real-time control can cut energy use without compromising capture performance. The result is a dust collection system that adapts to production needs, reduces wear on equipment, and provides valuable operational data for continuous improvement.

Achieving this level of performance starts with the right system design. Partnering with a qualified engineering firm ensures that ductwork, filtration equipment, and control logic are matched to the specific needs of your processes—and that safety, compliance, and efficiency are built in from the start. Experienced engineers can model airflow, balance branches, and select control strategies that protect capture velocities while maximizing energy savings. Whether upgrading an existing system or designing a new one, investing in expert design and commissioning pays off in cleaner air, lower operating costs, and reliable long-term performance.