Reimagining Dust Filtration for Market Needs

In traditional setups, centralised dust collection systems have been widely adopted. However, WAMGROUP has seen a growing shift toward spot and stand-alone filter units, which offer several clear advantages in terms of efficiency, safety, and environmental sustainability.

In these systems, dust is filtered directly at the source—where it is generated—and is then immediately reintroduced into the process. This minimises waste and ensures a clean working environment around the equipment. Such equipment also eliminate the need for extensive ducting, which reduces energy losses due to pressure drop and simplifies system design.

From a practical standpoint, these compact units are easier to maintain, often without requiring highly specialised personnel. They are ideal for facilities with space constraints or those seeking to reduce their environmental footprint while maintaining operational flexibility.

A Proactive Approach to Environmental Stewardship Dust emissions in dry bulk handling are a serious environmental concern. Fine particles released into the atmosphere contribute not only to visual pollution but also to air quality degradation, affecting local ecosystems and communities. Certain types of dust, depending on their composition, can even be classified as hazardous and subject to regulatory limits on emissions.

WAMGROUP’s spot filtration units, by capturing dust at the source, significantly reduce fugitive emissions, helping customers comply with air quality standards such as ISO 14001, ATEX, and various national clean air regulations. The recycling of filtered dust back into the process also reduces landfill waste and material loss, supporting a circular economy model in production environments.

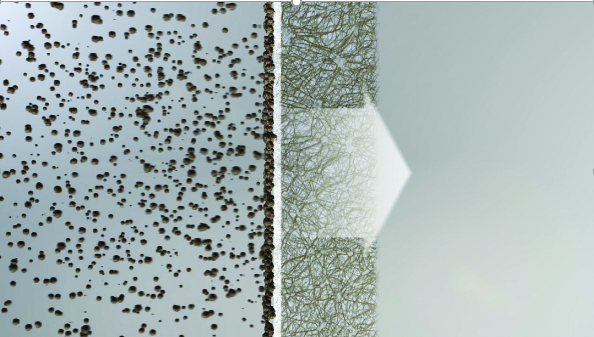

Moreover, the company’s ongoing research into nano-fibre filter media has led to dramatic improvements in filtration efficiency. These advanced materials are capable of capturing submicron particles with high reliability, reducing the environmental impact of even the most demanding processes.

Prioritising Employee Health and Workplace Safety

Airborne dust isn’t just an environmental issue—it’s a critical occupational hazard. Prolonged exposure to fine dust can lead to serious health conditions such as silicosis, respiratory allergies, and even certain forms of cancer, depending on the materials handled. It can also create slippery or explosive atmospheres, posing serious safety risks to employees and equipment.

By enabling localised filtration, WAMGROUP’s equipment solutions greatly reduce the concentration of airborne dust near operating personnel. This leads to cleaner, safer work environments with improved visibility, better air quality, and lower risk of respiratory exposure.

The company also places strong emphasis on ease of maintenance and operational safety. Many of the stand-alone units are designed for tool-free access, equipped with features like automatic cleaning systems (pulse jet), and offer easy filter element replacement. This reduces downtime, prevents unnecessary exposure to dust during maintenance, and supports a culture of safety in the workplace.

Built to Last: Filters for the Harshest Environments

Industrial environments can be harsh—exposure to moisture, corrosion, abrasion, or high temperatures is common. To meet these challenges, WAMGROUP offers dust filtration units with stainless steel casings, ensuring exceptional durability and long service life even in the most extreme conditions.

These robust materials not only extend equipment lifespan but also reduce the risk of leaks or failures that could lead to uncontrolled emissions or hazardous dust accumulation. This reinforces the system’s reliability and further aligns with environmental compliance goals.

Innovative Filter Design for Lasting Performance

Dust filtration efficiency is not only about the quality of the media but also the geometry and structure of the filter elements. WAMGROUP has invested in advanced R&D to develop semi-open and open-profile geometries that ensure a useful filtering surface area extremely close to the theoretical maximum. This design innovation delivers consistently high filtration performance over time and reduces the frequency of filter media replacement.

Combined with the nano-fibre filter technology, this results in a powerful system capable of addressing a wide range of industrial dust challenges—from fine powders to abrasive or sticky materials—with minimum maintenance and exceptional operational continuity.

Specialised Solutions for Every Application

WAMGROUP recognises that every facility has unique requirements. That’s why its filtration solutions are available in multiple configurations—round or polygonal, vertical or horizontal installation, with various discharge systems (e.g., bin, rotary valve, screw conveyor). The company also offers an extensive range of filter media types, each selected based on the properties of the dust and the demands of the process.

Whether in cement, food, chemical, plastics, or mining industries, WAMGROUP provides specialised, high-efficiency filter units that offer peace of mind in terms of compliance, performance, and sustainability.

Conclusion

As environmental regulations tighten and expectations for worker safety grow, companies must act decisively to manage dust emissions. WAMGROUP’s stand-alone and spot filters —compact, customizable, and technologically advanced—are not only a smart investment in efficiency, but a meaningful step toward a cleaner planet and a safer workplace.