With the agitator and auger working together to promote consistent flow, Trantec feeders are designed to minimise buildup and clogging, delivering continuous, uninterrupted operation. They offer accurate dosing from milligrams to tonnes per hour, reduce material waste, and maximise consistency, keeping both your product quality and your bottom line stable, batch after batch.

Whether you require a straightforward volumetric feed or more advanced gravimetric (weight-based) control, the True-Flow Feeder system adapts seamlessly to your process requirements. From fine powders to free-flowing pellets, cohesive powders to abrasive granules, the series handles it all with ease. With interchangeable auger and agitator options, these feeders are capable of delivering outstanding performance across industries, including plastics, chemicals, food and nonwoven.

Where Quality Meets Cost-Competitiveness

The True-flow feeder range is the result of smart engineering and smarter manufacturing, with the journey from concept to delivery happening entirely under one roof. From the custom-made seals to the precision-machined auger, and fabricated stainless parts are all manufactured in-house, giving Trantec complete control over quality, timelines, and costs. This integrated approach allows the company to cut unnecessary markups, eliminate delays from third-party dependencies, and pass significant savings on to customers. The result? A superior machine at a price that is truly competitive. In addition, their investment in advanced CNC machinery, paired with high-skilled fabricators and an expert design team, creates smart production efficiencies. These efficiencies enable Trantec to deliver reliable, high-performing feeders that won’t break the bank.

Reducing Lead Times with Ready-to-Ship Feeders

Moving forward, Trantec is also working towards making the True-Flow feeder line available off the shelf, a game-changer for operations that need reliable, high-performance feeders without delay. This approach not only shortens lead times and speeds up deployment, but also reduces overall unit costs by eliminating custom build times and minimising material waste. By standardising key models, producing in volume, and streamlining component designs, Trantec significantly lowers manufacturing costs, savings that are then passed directly to customers without compromising on quality or performance.

Smart design that adapts to your process

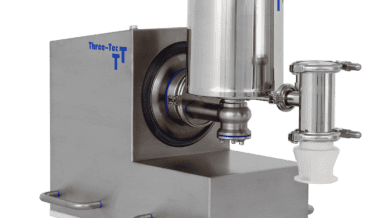

Trantec’s True-flow feeder range isn’t a legacy product with a facelift, it’s a clean-sheet design that reflects today’s industrial feeding needs. While it excels in simplicity, advanced features can be seamlessly integrated when applications demand it. They offer, in addition, a quick-release front panel that promotes ease of cleaning and reduces downtime. For ultra-low dosing requirements, the Micro Feeder version delivers outputs from milligrams to grams per hour, ideal for precision-critical sectors like chemical, food, and nuclear industries. Alongside, Pharma-grade variants are also available, featuring highly polished internal surfaces (up to 0.2Ra) and specialist contact parts that minimise cross-contamination and speed up wipe-down times.

Value Without Compromise

Trantec delivers real value without sacrificing quality. With competitive pricing driven by fully in-house manufacturing and continuous design refinements, Trantec’s True-Flow Feeders represent a new generation of precision feeders, combining robust stainless steel construction with modular simplicity. These feeders offer outstanding versatility, configurable for multiple feed modes and material types, while their intuitive design ensures easy operation and minimal maintenance. Designed for performance across diverse industries, from everyday bulk handling to ultra-sensitive pharmaceutical feeds, they’re now becoming available off the shelf for even faster deployment.

If precise, consistent material feeding is essential, but you also value cost-effectiveness and simplicity, the Trantec True‑Flow Screw Feeder delivers exactly the right balance. Email sales@trantec.net to speak with an engineer or visit www.trantec.net for further information.