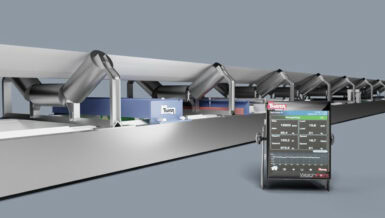

Thayer Scale’s vibratory feeders provide a uniform, non-pulsating flow of difficult-to-discharge materials (fiberglass strands, products with low melt points, fragile materials such as dehydrated fruit additives, etc.) over a wide operating range without the need to make any mechanical adjustments over the entire flow rate range.

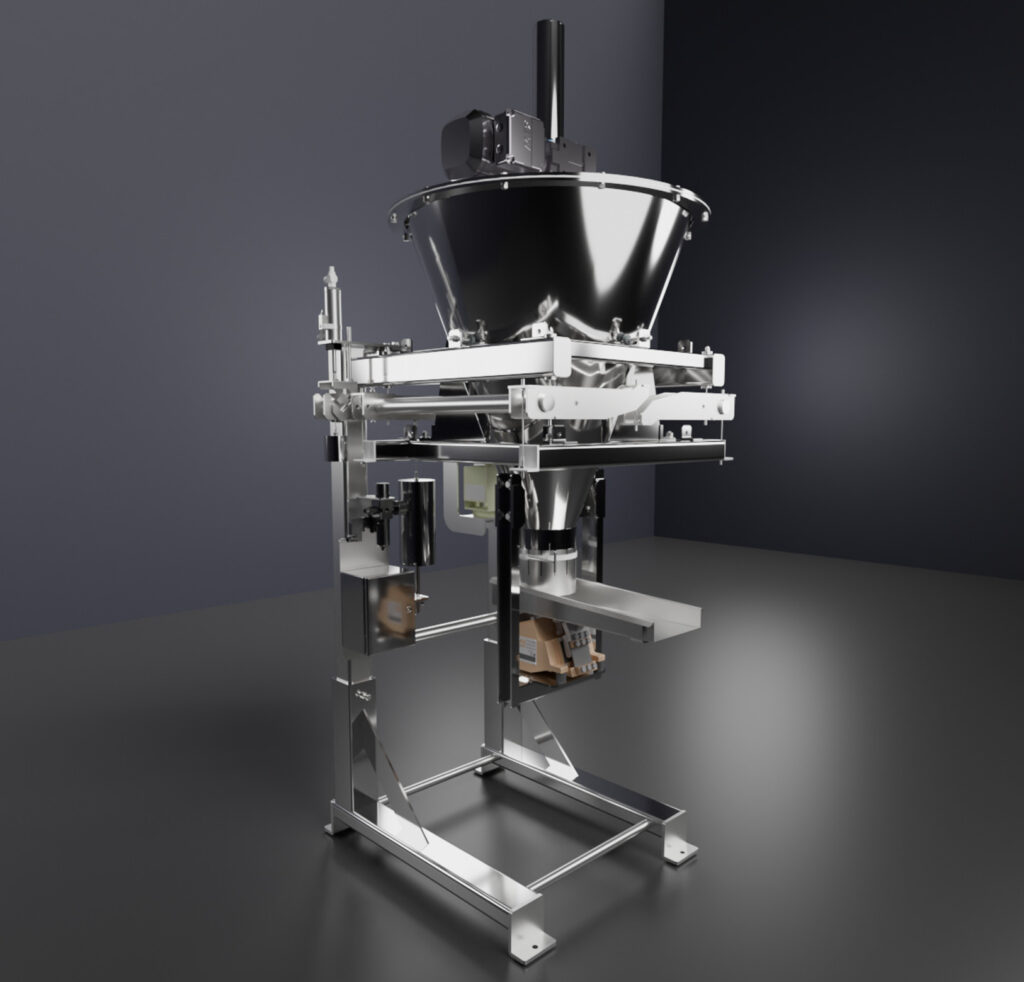

Design options allow vibratory trays to dispense material at a single point or spread across a wide band. Thayer Scale models feature a unique, counter-rotating agitation system that gently dilates material for reliable material flow through the weigh hopper to the vibratory tray. At the heart of any gravimetric feeder is its scale system. Thayer Scale’s patented Force Measurement Suspension System (FMSS) cable scale technology is the most rugged and forgiving Load Cell weighing system available on the market.

Some Thayer Scale Loss-In-Weight feeders incorporate an Automated Test Weight Lift (ATWL) and Storage assembly, which automates the application of a known test load during the calibration sequence to validate system measurement performance without putting operators at risk by climbing ladders and lifting/positioning heavy weights. An added benefit, vibratory feeders feature no moving parts, simplifying preventive maintenance.

Benefits:

- Nulls out heavy tare loads for maximum load cell utilization and accuracy

- Gentle and precise handling of a wide range of materials

- Easily accessible load cell can be accessed without removing the feeder

- Immune to shock or impact loads

- Provides immunity to support structure deflections and process vibrations

- Allows the feeder to be moved frequently without damage or zero drift

- Inherently self-aligning to gravity