These Belt Scales have been proven in applications demanding ±0.125% accuracy through independent certification.

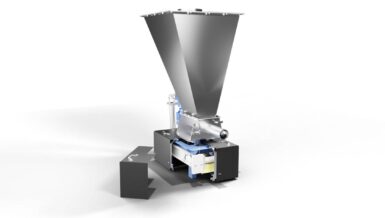

The weigh bridge features exclusive rocking flexure suspension in the approach-retreat configuration. Measurement sensitivity is high, deflection is low, and the load cell is isolated from the error-inducing effects of extraneous lateral forces, off-center loading, foundation distortion, inclination hold-back forces, high sporadic shocks and overloads as well as belt tension changes which affect the scale “Zero”, the critical foundation and basis for accuracy in any continuous weighing application. Tare load is mass counterbalanced to create superior signal to noise ratio in weight sensing, orders of magnitude better than belt scale designs supporting full tare load on the load sensor. Thayer Scale builds 1, 2, 3, 4, 6 and 8 idler belt scales supporting belts from 14 to 96 (and over) inches wide.

Accurate belt speed measurement requires the use of a precision wheel and pulser. A spring is used to maintain proper contact pressure of the wheel with the tension side of the belt in all operating conditions. The Thayer Scale belt travel pulser assembly includes a precision cast/machined wheel with a “pre-calibrated” circumferential tolerance of ± 0.05% and a high-resolution digital transmitter. The transmitter produces pulses equivalent to 1/100 to 1/200 of a foot of belt travel. The speed pick-up wheel has a narrow face width so it is less susceptible to material build-up, which can result in speed measuring errors. Since belt stretch is not constant throughout the length of the conveyor, which can affect speed measurement, the speed pickup produces a more accurate speed signal than that which is produced by tail pulley-mounted speed encoders.

The distinct specification of continuous belt scale weighing applications and the unique environment and operational issues those applications typically encounter place too many requirements on the load sensing system for any single technology to completely satisfy. Therefore, using Thayer Scale’s exclusive Force Measurement Suspension System FMSS technology in the design of its belt scale suspension system allows the choice of using either its LC‐137 LVDT Load Cell or its LC‐174 Strain Gauge Load Cell. This puts Thayer Scale in a unique position to offer equipment to match a wide range of applications such as light material loading, severe environmental conditions, and commercial certification. Thayer Scale can provide an accurate reliable calibration using easily applied calibration weights instead of test chains for all scale capacities.

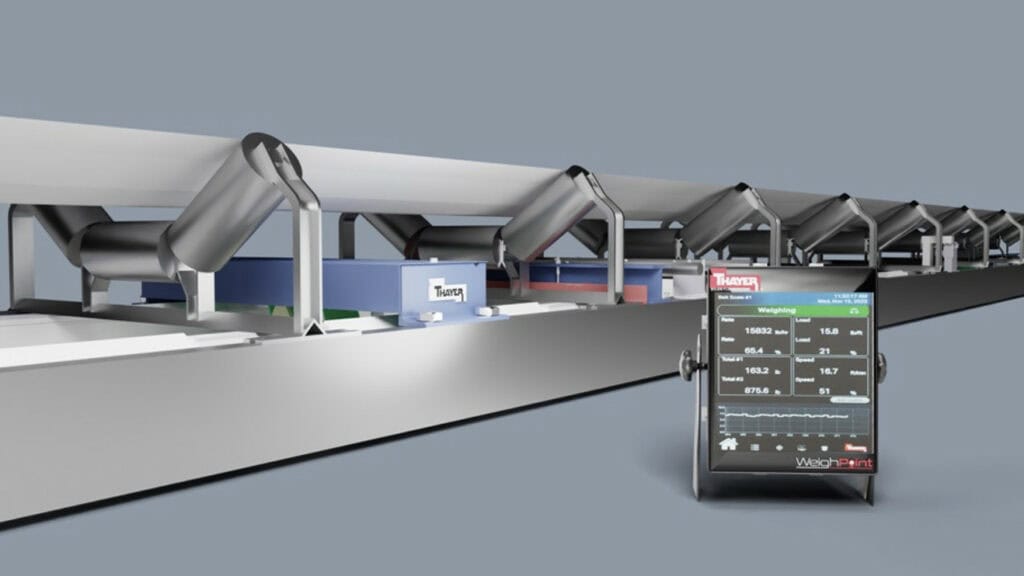

Thayer Scale’s new WeighPoint™ Integrator is a dual-processor, touchscreen-enabled solution designed for continuous operation in harsh environments. The field-mountable or panel-mountable standalone unit with HMI provides an easy-to-use interface to the company’s deep library of algorithms and functions. It is the most robust conveyor and belt-weighing integrator system on the market. WeighPoint™ 7200 is designed for use with Thayer Scale’s versatile range of RF belt scales for optimal weighing accuracy and performance. The integrator is packed with features and is available in four configurations for flexible installation planning.

Key Advantages of NTEP Certified Belt Scales:

- A weighbridge that features an exclusive rocking flexure suspension system for both Approach and Approach/Retreat configurations

- High measurement sensitivity, low deflection, and a single load cell that is isolated from significant error-producing forces including:

- Extraneous lateral forces

- Off-center loading

- Foundation distortion

- Inclination holdback forces

- High sporadic shocks and overloads

- Conveyor Belt Scales – Mass-counterbalanced tare loads to create a high signal‐to‐noise ratio in weight-sensing

- Proven immunity to zero biases and shifts, resulting in a stable scale zero—the foundation of all continuous weighing devices (conveyor belt scales)

- Test weights to physically exercise the scale lever (we avoid resistor calibration, which can mask systemic errors in the belt scale installation)

- A fixed-circumference precision belt-travel sensing wheel simply mounted to the conveyor stringers using four bolts

Thayer Scale has been manufacturing belt scales for 75 years. It offers a competitive line of belt scales and a wide range of upgrade paths for customers of competitive equipment.