At the same time, the degree of precision in determining this data often affects the profitability of the process, especially with small quantities and expensive materials, since too many rejects already entail high costs when processing starts.

German company SIEBTECHNIK TEMA has now addressed this problem with the development of a unique gas pycnometer that fully automatically measures the volume and mass of a solid with the highest precision. The innovative “BULKINSPECTOR” provides the kind of safety in process preparation that is needed for trouble-free production and further processing.

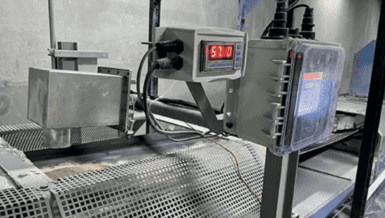

In addition to its high precision, the “BULKINSPECTOR” is primarily characterized by the fact that it measures both the mass and volume of the solid fully automatically. Unlike older pycnometers, the sample is inserted into the measuring cell by means of a sample-handling device instead of old-fashioned manual filling. Using a sample magazine, even various substances can be analyzed in a very short time and without any human intervention.

After calculating the density from the parameters volume and mass in the “BULKINSPECTOR”, the handling device removes the respective measuring cup and transports it to the integrated emptying device, where the cup is cleaned using compressed air. After that, it is ready to receive the next sample. Since the volumes of the measuring cups and the samples must match each other for precise measurement, the fully automatic gas pycnometer works with a selection of different measuring cups with predefined volumes, which are kept in parking positions inside the device.

The interior of the insulated system housing is covered with Peltier elements and can be heated or cooled as required to keep the temperature of the material constant for the measurement. In addition to the integration of further technical features, such as a sophisticated automatic calibration facility, the SIEBTECHNIK TEMA engineers paid particular attention to reproducible measured data with low standard deviation when designing the “BULKINSPECTOR”, both with regard to the mechanical measuring structure and the selection of the sensors.

Operation of the device is also state-of-the-art and is carried out via a supplied tablet on which an app integrates the user into the settings of the “BULKINSPECTOR” by means of a user-friendly interface. This interface can be used, for example, to make the basic settings of the device, to set individual recipes for different samples, or to manage measurement protocols and output them via WLAN. In addition, the control system supports the division into password-protected operator levels and the on-demand request for required spare and wear parts directly from the manufacturer. The new “BULKINSPECTOR” from SIEBTECHNIK TEMA represents the latest state-of-the-art technology in the field of solid density measurement, which is probably soon to become the global standard.