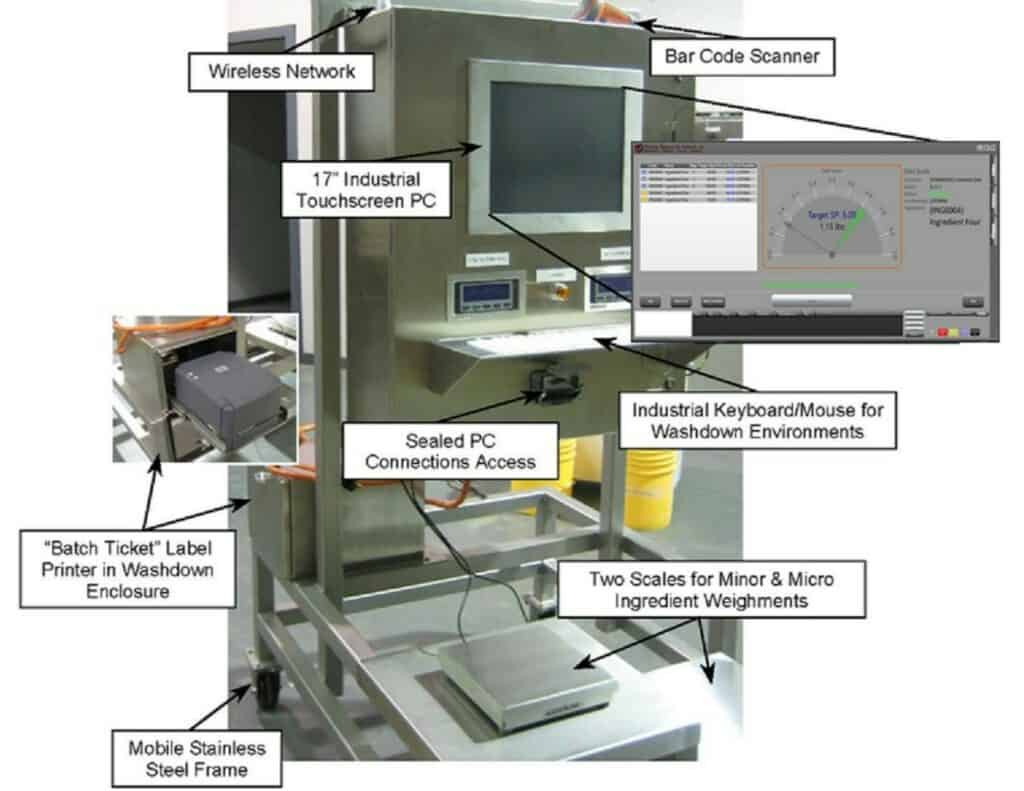

The Hand Prompt Batching Station is a semi-automatic batching system that requires operator involvement, but provides customized automated operator instructions or “prompting”, ingredient lot tracking and batch validation, automatic weighing with over/under tolerance control, etc. This system will eliminate bad batches that result from operator error and interruption. The operator no longer needs to keep track of where he is in the batching process as the Semi-Automatic Hand Prompt Batching Station does that for you automatically. No missing ingredients! No bad batches! The Semi-Automatic Hand Prompt Station can be combined with and provided with a platform scale, floor scale, bag dump scale, and multiple scales.

The Sterling Systems Semi-Automatic Hand Prompt Batching Station PC will ask the operator to weigh ingredients. The Hand Prompt Controller will sequence an operator through the selected formula one ingredient at a time. The primary advantage of the system is to ensure that each ingredient added to the batch container is within a programmed weight tolerance, and from the correct ingredient lot (using barcode scanning or manual entry) before the controller will index to the next ingredient to be added. This ensures the validity of the batches created by the operator.

The Semi-Automatic Hand Prompt Batching Station provides real time records for each batch produced, enabling the highest standards to be maintained by ensuring a consistent batched product. As batches are produced, the batching controller records the batch data and can print batch reports to a ticket printer. Additional reports and data can be printed on a standard network printer (batching station will need to be connected to your network) if one is available.