In additive manufacturing (AM), a key question is: Can this powder be printed? Researchers, manufacturers, and engineers benefit from assessing processability without costly and time-consuming print trials. While good powder behaviour doesn’t guarantee high-quality parts, it’s a critical first step.

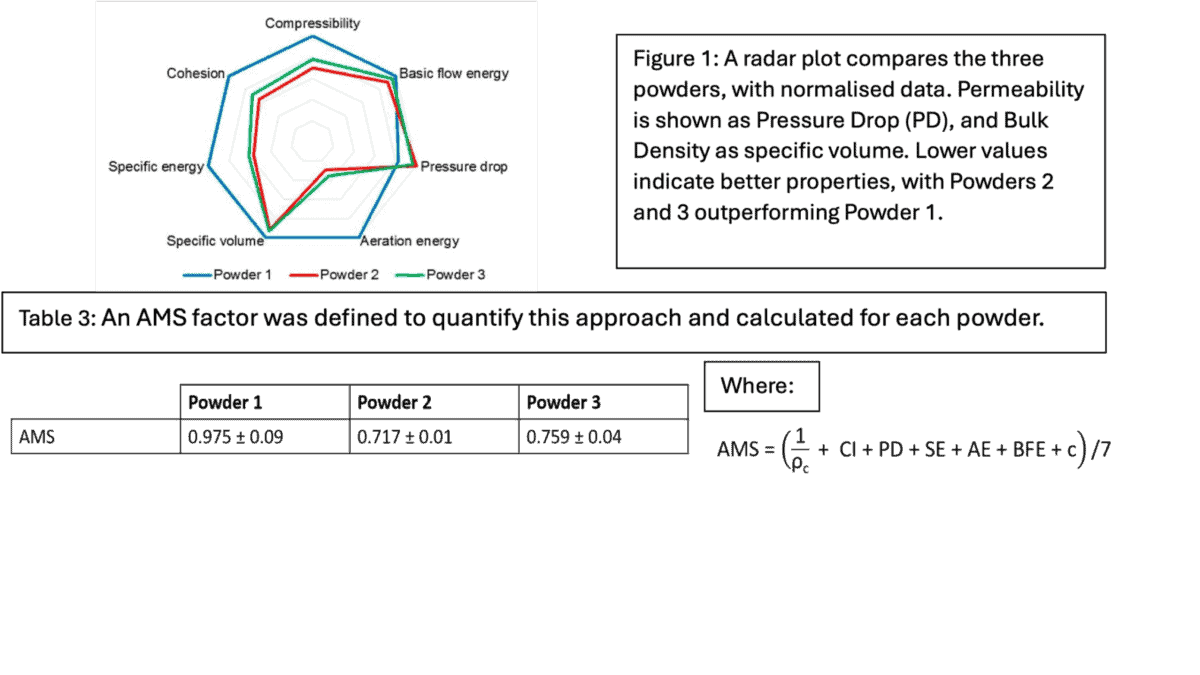

A consensus is emerging on key powder properties—particularly flowability and spreadability—that determine printability. Researchers at École de Technologie Supérieure (Montreal, Canada) developed an Additive Manufacturing Suitability (AMS) factor, later applied by Oerlikon AM (Feldkirchen, Germany). Their work shows how dynamic, shear, and bulk properties, measured with the FT4 Powder Rheometer® (Freeman Technology) can reliably predict printability.

Establishing AMS

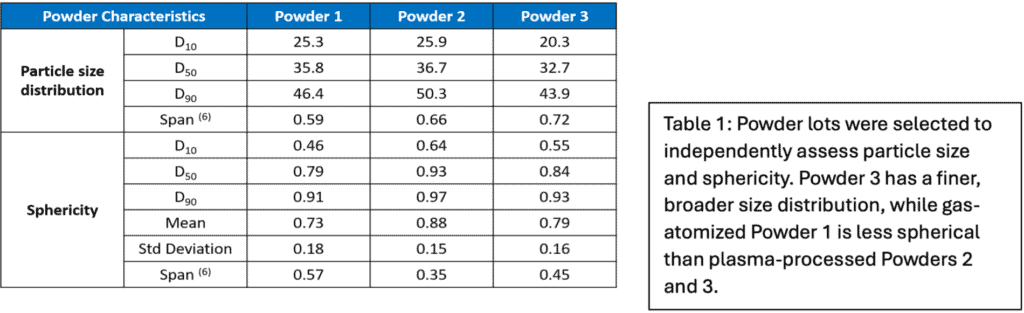

Researchers analysed three Ti-6Al-4V powders in a laser powder bed fusion (LPBF) printer (M280, 400 W, EOS GmbH), selecting gas-atomised (Powder 1) and plasma-atomised (Powders 2 and 3) lots to isolate the effects of particle size and shape. Table 1 presents particle size and sphericity, measured via computer tomography. While Powders 1 and 2 share similar size distributions, Powder 3 is finer with a broader range. The higher sphericity of Powders 2 and 3 reflects their plasma atomisation process.

Assessing Printability

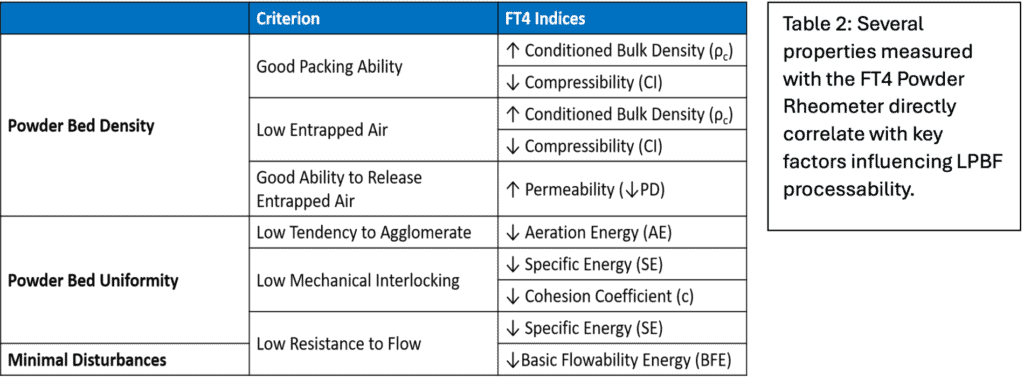

Bulk powder properties were measured to assess the impact of particle size and shape on LPBF print quality. Success relies on forming uniform, dense layers with minimal disruption. Seven key properties were identified using the FT4 Powder Rheometer (Table 2): dynamic (BFE, SE, AE), bulk (CI, permeability, Pc), and shear (cohesion).

Powder 2 ranks best (lowest AMS value), highlighting particle shape has a greater impact than size. Despite size differences, Powders 2 and 3 exhibit similar properties, while Powder 1 scores lower due to its irregular shape.

Printing trials at 30µm and 60µm layer thicknesses evaluated powder bed density, part density, surface finish, design resolution, and tensile strength. While detailed data is beyond this scope, results show Powder 2 forms denser powder beds and superior printed parts. Notably, Powders 2 and 3 at 60µm performed similarly to Powder 1 at 30µm, suggesting faster processing speeds with better powder selection. This validates AMS rankings as a valuable tool for supply comparison.

Traditional flowability tests (Hall and Gustavsson flow meters, tapped density methods) ranked the powders similarly but lacked differentiation. Tapped density methods classified all as “excellent,” while Hall and Gustavsson meters gave inconsistent insights. None effectively linked particle size and shape to powder behaviour during recoating.

In contrast, the AMS factor approach:

- Sensitively differentiates powder quality,

- Enhances understanding of particle size and shape effects,

- Applies universally across powders,

- Allows refinement, e.g., by adjusting weightings for greater sensitivity.

Using the AMS Factor

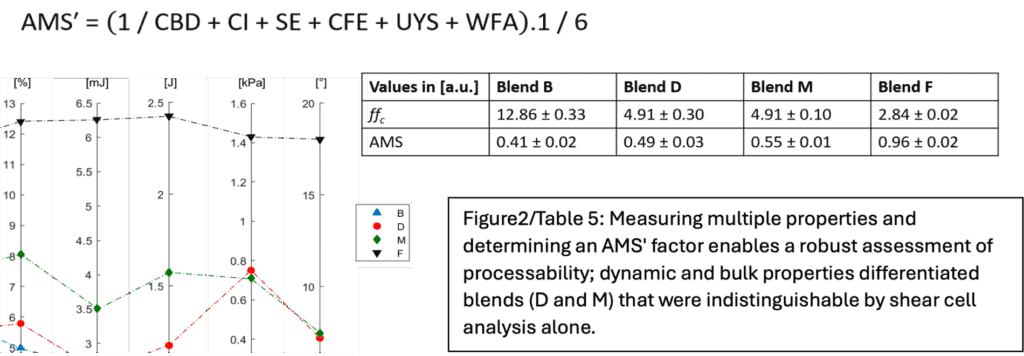

Oerlikon researchers applied AMS to assess powder blend processability for in situ alloying in LPBF. While LPBF enables on-the-fly alloying, blend processability remains crucial. A modified AMS factor (AMS′) ranked four blends: Blend B (baseline, Inconel 718 + CoCr75) and Blends D, M, and F (elemental fines with varying Co and Cr size/morphology). AMS′ replaces permeability and AE with Consolidated Flow Energy (CFE) and Unconfined Yield Strength (UYS) while adding Wall Friction Angle (WFA) for enhanced shear property assessment.

This study highlights the limitations of simple techniques like the Hall Flow Index for assessing complex elemental blends and notes the value of shear, dynamic, and bulk testing for deeper analysis. While shear data failed to distinguish Blends D and M, bulk and dynamic properties revealed clear differences, reinforcing the benefits of a multi-technique approach. The AMS′ factor effectively summarises key properties and serves as a reliable indicator of processability. AMS′ trends correlate with increasing fines content, though morphology also plays a role—Blend F, despite its high fines content, exhibits lower sphericity, explaining its outlier behavior.

Refining AMS′ through weighted adjustments remains an area for exploration. However, in this case, chemistry adds complexity in linking powder rheology to printed component properties.

Conclusion

These studies demonstrate the potential of combining multiple powder properties, measured with the FT4 Powder Rheometer, into a single metric for AM suitability. Dynamic, shear, and bulk properties collectively quantify critical behaviors like flowability, packing efficiency, air release, and compressibility. By integrating multiple relevant parameters, the AMS factor provides a robust measure of processability, enabling differentiation of supplies, assessment of particle size and morphology changes, and identification of high-performance materials.

DON’T WAIT – CONTACT US TODAY!

ATA Scientific Pty Ltd | Ph: +61 2 9541 3500 | enquiries@atascientific.com.au | www.atascientific.com.au

Reference:

Freeman Technology, “New research establishes the concept of an ‘AM Suitability’ factor for metal powder selection,” Freeman Technology, Jan. 24, 2022. [Available: https://www.freemantech.co.uk/news/the-concept-of-an-am-suitability-factor-for-metal-powder-selection]