Intelligent contaminant detection systems are key to minimizing these risks. However, even the most advanced technologies are not immune to performance drift. With fast-moving production and increasingly complex supply chains, maintaining consistent inspection accuracy is critical.

“Brand protection begins at the point of prevention,” states Eric Garr, Regional Sales Manager at Fortress Technology. Like any precision equipment, inspection systems require routine calibration, maintenance and testing to sustain optimum sensitivity, ensure fail-safe functionality and remain a reliable preventive control.

Why Automate Performance Checks?

Ultra-sensitive inspection systems are vital for food safety. Yet, their reliability hinges on the strength of the processes supporting them. Investing in innovative technology without implementing routine checks, automated testing and digital data collection undermines its effectiveness, increasing the risk of undetected issues at the final checkpoint.

High-throughput wholesale, ingredient and food processing environments amplify these challenges. Under GFSI and HACCP standards, every industrial food metal detector must be tested using ferrous, non-ferrous and stainless-steel test samples at the start and end of each shift, sometimes hourly and between every product changeover.

With output per hour being a critical productivity metric, machine uptime on any heavy product application inspection line is essential. Manual testing is time-consuming, vulnerable to human subjectivity and error, and often difficult due to the weight of packaged products, equipment positioning and access difficulties. Maintaining the proper oversight required from modern food safety standards without automation is resource intensive, error-prone and a constant challenge to document consistently.

A Practical, Scalable Alternative

Automated testing systems are reshaping how food processors verify inspection performance. By replicating the presence of contaminants at a pre-programmed “worst-case” positioning in the product flow or pack, they remove the guesswork, variability and safety risks inherent in manual testing. Tests can be triggered manually, remotely or run automatically on a schedule, ensuring consistent results without interrupting production.

Key benefits include:

- Standardized, reliable testing free from human error

- Reduced labor and operational costs

- Improved workforce safety by removing manual test procedures

- Reduced product waste by avoiding test sample recovery

- Increased uptime, throughput potential and opportunities for growth

- Tamper-proof digital audit trails that support compliance and traceability

- Ability to increase test frequency without requiring more labor.

Fortress Technology’s Halo Automatic Test system exemplifies this approach. It generates a calibrated signal mimicking a metal contaminant while delivering real-time, verifiable data. By eliminating the risk of missed or inaccurate tests, manual subjectivity and data gaps, Halo enables processors to maintain QC standards without slowing production.

The ROI can be rapid. With daily Run Time Equivalent (RTE) costs estimated at $200 – $250 per metal detector and entry-level production supervisors earning an average of $56,616 annually in North America, labor savings alone can recoup the investment in a matter months.

One company already seeing tangible results is Ardent Mills, a leading North American flour and ingredient producer. With over 22 million bags of milled product processed and packed annually, Ardent activated the Halo software on several of its Fortress conveyor metal detectors. A built-in blue light indicator now clearly distinguishes test cycles from contamination events, eliminating unnecessary rework and waste. “This feature alone has significantly reduced product waste,” states Packaging Engineer Manvine Bharj. “Without it, we’d potentially have to manually re-inspect up to 600 lbs of flour per line, per shift.”

Supporting Interoperability

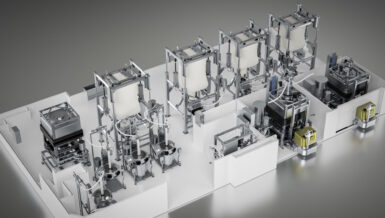

Automation is only part of the equation. To unlock the full potential of Industry 4.0, inspection technologies must integrate with broader strategic plans, ensuring that data is actionable across an entire production facility, as well as scalable.

The Food Safety Modernization Act (FSMA) highlights this need, prioritizing digital record-keeping, end-to-end traceability, and predictive analytics. Former FDA Deputy Commissioner and food traceability pioneer Frank Yiannas put it simply: “A standardized, data-driven approach to traceability recordkeeping helps create a universal language of food traceability, paving the way for interoperable, tech-enabled systems.”

Technologies like Contact 4.0 deliver exactly this. Using OPC UA connectivity, multiple machines can be networked to provide a single view of inspection performance. This live data helps processors generate full-site compliance reports, track Overall Equipment Effectiveness (OEE), and feed performance insights directly to QA and technical teams.

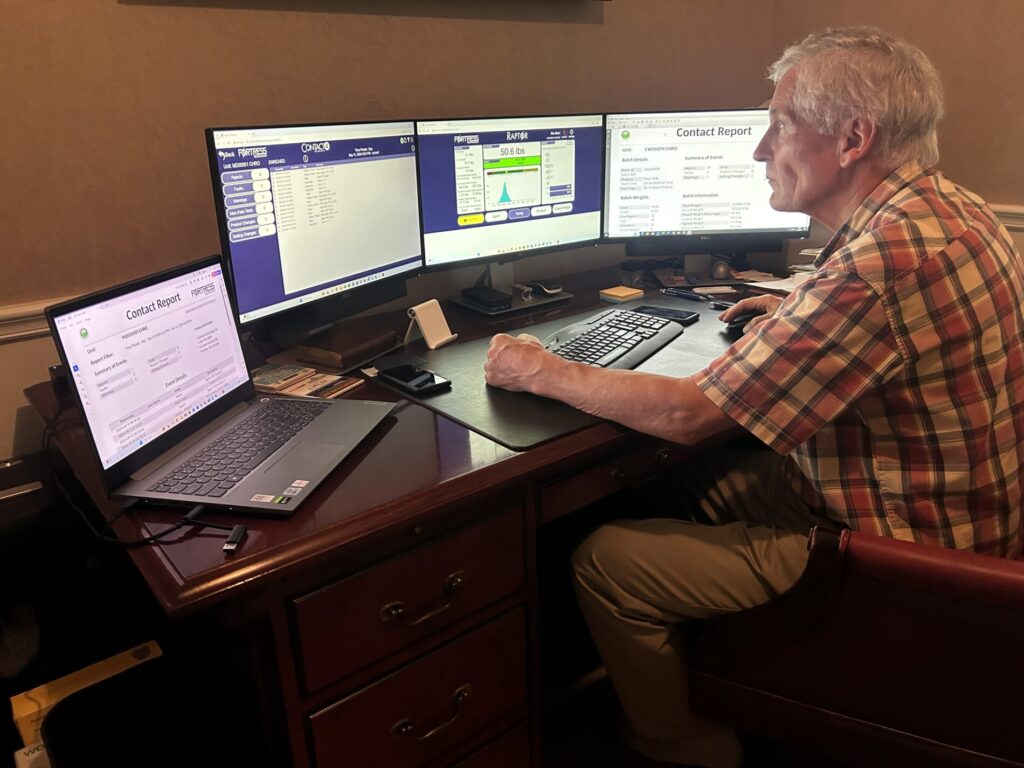

Tethering multiple front-end production machines to back-end reporting software in real time, Fortress Technology’s Contact 4.0 solution has enabled real-time monitoring across several Mennel Milling facilities in the U.S. “Every morning we receive an automatically generated report to support our decision-making,” explains Senior Corporate Packaging Engineer Dieter Flick. “Contact 4.0 displays checkweigher histograms, reject data, and product giveaway trends, helping us pinpoint upstream filling issues before they escalate.”

Maximizing Safety and Productivity Potential

As food factories become increasingly connected, the volume of available data offers unprecedented control over production, efficiency and safety. By automating inspection testing, centralizing data and utilizing digital analytics, food processors can detect faults faster, act on issues sooner and maintain full traceability with ease.

“Connectivity is the foundation of any digitization strategy,” says Eric Garr. “The real value comes from how the data is analyzed – identifying trends and patterns that drive smarter business decisions.”

Industry 4.0 isn’t just about adopting new technology; it’s about connecting and optimizing the systems you already rely on. For food processors operating in any sector, the payoff is clear: fewer errors, less waste, and a safer, more efficient supply chain.