BinMaster offers a suite of radar and ultrasonic level sensors that, when integrated with BinCloud® inventory software, provide real-time visibility into material levels in bins, silos, and tanks. This powerful combination is transforming how food processors monitor and manage bulk ingredients like flour, sugar, grains, and liquids.

Radar and Ultrasonic Sensors: Tailored for the Food Industry

Food processing facilities often store a variety of dry and liquid ingredients in bulk containers. The environmental conditions in these facilities—such as dust, humidity, temperature variations, and hygiene requirements—can make level measurement challenging. BinMaster addresses these issues with radar and ultrasonic sensors designed specifically for tightly controlled and sanitary environments.

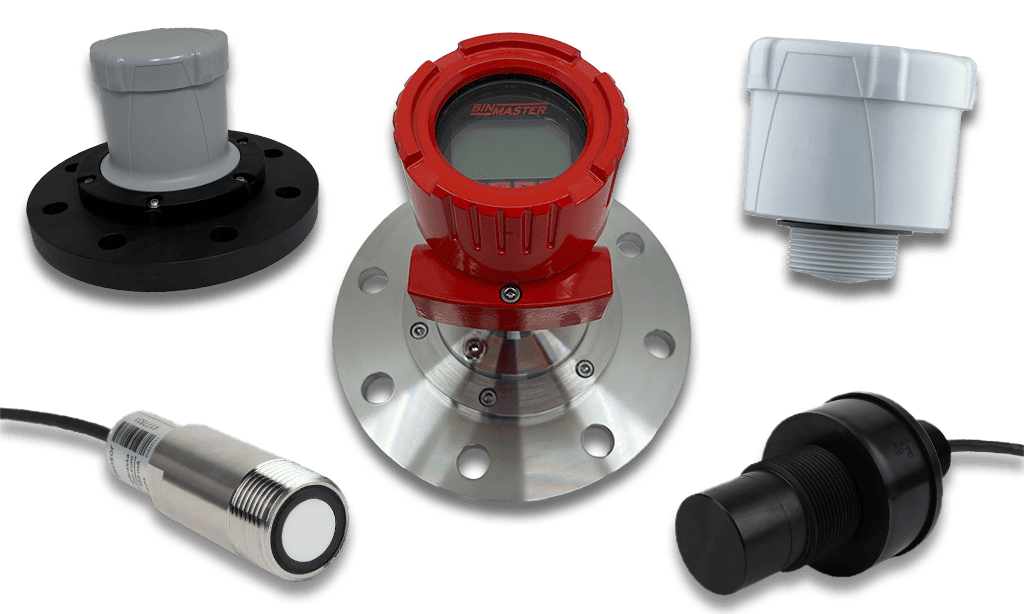

Radar sensors such as BinMaster’s non-contact 80 GHz models use high-frequency electromagnetic waves to accurately measure levels of solids and liquids, even in dusty or steamy conditions. The NCR-86 sensor is ideal for tall silos, dusty ingredients, or challenging environments like flour storage bins.

CNCR series radars are best suited for smaller vessels and processing environments due to their compact size and quick update rates. By retrieving non-contact measurements, radar level sensors meet sanitary standards and reduce contamination risk, a critical requirement in food-grade applications.

On the other hand, ultrasonic sensors use sound waves to detect material levels. They are utilized for short-range liquid and slurry applications in ingredient hoppers and small tanks. BinMaster’s ToughSonic® ultrasonic sensors offer cost-effective, reliable performance for facilities where radar may be overkill or unnecessary.

Integration with BinCloud: Real-Time Visibility and Control

While sensors provide critical data, the real power comes from its integration into a centralized platform. BinCloud inventory management software collects readings from all connected BinMaster sensors and presents them in an easy-to-use dashboard that can be accessed from any device with internet connectivity.

With BinCloud, food processors can:

- Monitor multiple locations in one interface

- Receive automated alerts when inventory levels drop below preset thresholds

- Generate usage reports and historical trends

- Optimize reorder points and deliveries

- Improve compliance with food safety and traceability requirements

BinCloud integration reduces manual inventory checks, which are not only time-consuming, but can also pose safety risks—especially when workers must climb silos or enter confined spaces. With BinCloud, the entire operation becomes safer, more efficient, and highly accurate.

Benefits for the Food Processing Industry

The combination of BinMaster sensors and BinCloud software brings measurable improvements across food processing operations:

- Minimized Downtime: By continuously monitoring ingredient levels, facilities avoid unexpected outages that can halt production.

- Reduced Waste: Precise tracking means fewer expired or spoiled materials and better rotation of raw goods.

- Improved Planning: Historical data analysis supports better forecasting and purchasing decisions.

- Regulatory Compliance: Automated recordkeeping helps meet food safety audits and reporting standards.

- Labor Savings: Fewer manual checks free up employees for higher-value tasks and reduce exposure to hazardous environments.

Real-World Applications

For example, a cereal manufacturer might use BinMaster radar sensors in tall silos holding oats, plus ultrasonic sensors in smaller additive bins for flavorings. These sensors feed real-time data to BinCloud, which not only alerts managers when to reorder, but also helps forecast usage patterns based on seasonality.

Similarly, a dairy processing facility might rely on radar sensors for liquid ingredients like milk or cream, integrating BinCloud data into its ERP system to synchronize supply chain activities and reduce spoilage.

Making Inventory Easier for Food Processors

The synergy between BinMaster’s radar and ultrasonic level sensors and BinCloud software reshapes inventory management in the food processing industry. By delivering real-time, remote visibility into material levels, these technologies enable food processors to increase operational efficiency, enhance safety, and maintain the exacting standards of quality required in today’s competitive market.

Whether managing grains, liquids, or powders, BinMaster and BinCloud offer a smart, scalable solution for modern food production challenges.