Minimising Material Build-Up

Getting the Right Profile

A mixer’s profile is often discussed from the perspective of ensuring all the material is mixed. However, the presence of ‘dead zones’ where the augers cannot reach and leaves mix constituents unmoved not only prevents homogeneity being achieved, it also allows material to sit and accumulate. A more tailored profile can help prevent this.

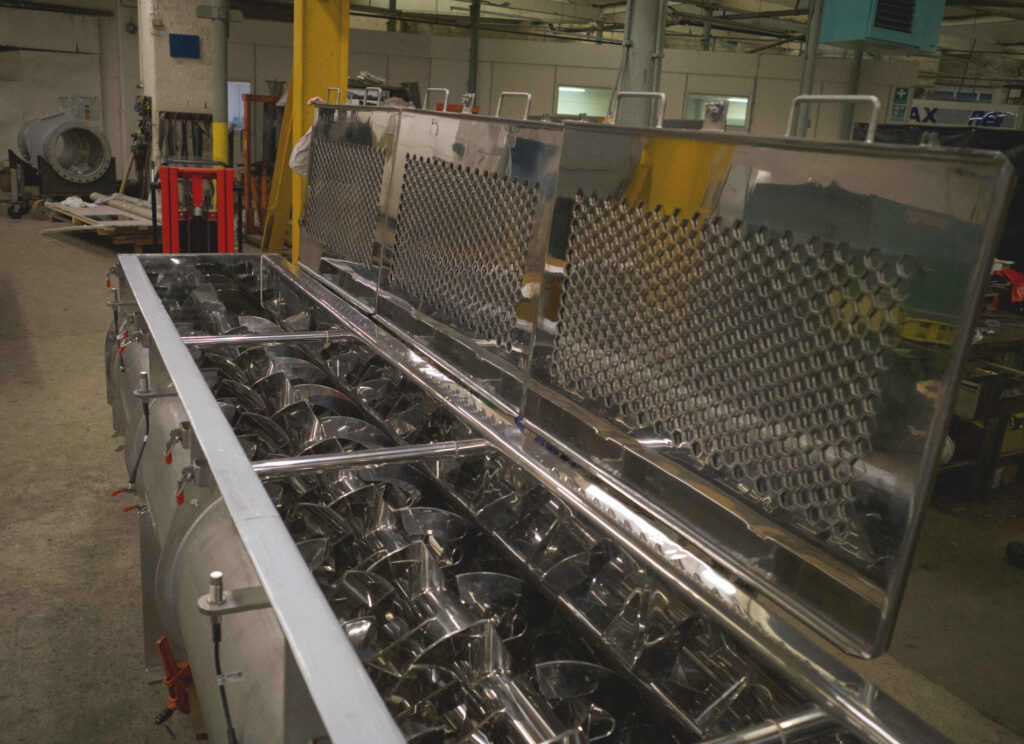

Ajax Equipment has developed a smooth mixer profile which follows the active sweep of the augers and prohibits the mix from becoming stuck. The casing still offers an upstand section fitted with covers to facilitate cleaning from above with complete line of sight assured. One customer who has benefited from this design on multiple mixers is leading European potato products producer Agristo, located in Belgium.

Selecting Flights

The right flight design is essential for efficient and effective mixing and is key in keeping the material moving along towards the outlet. Sticky materials, such as those that include syrups often used in cereal bar production, are particularly prone to building up on surfaces. Gentle mixing is sometimes preferred but full flights are very prone to build up. Instead, the open form of Ajax ribbon flights are more suitable for sticky materials as they inhibit the build-up of material reducing the frequency of interruptions for cleaning or maintenance.

Even paddle flights can be used successfully if the design is carefully considered. Ajax’s range of LynFlow™ paddle flights were developed to provide effective mixing whilst resisting material build-up because they significantly reduce the area closest to the shaft in contrast to standard quadrant type paddles which can be very prone to clogging.

The Finish

An often overlooked factor is the finish on the contact parts of the mixer. For the level of hygiene that pharmaceutical and food production demands, a crack and crevice free finish is essential to stop any, even small areas, that might trap product or allow bug growth due to the difficulty in properly cleaning the mixer. Some products might still adhere to surfaces even if they are quite smooth and make cleaning more laborious. To counter this, food grade mixers supplied by Ajax can be specified with an enhanced mirror polish finish. Recently one global food company, producer of one of the world’s leading brands of cereal bar, reported that cleaning times were drastically reduced with the enhanced polished parts Ajax supplied.

The mirror finish of all internal surfaces, including auger, flights, casing and covers, along with its tailored profile, helps prevent build-up and allows the mixer to be easily cleaned, while the whole cleaning process can be taken to another level of thoroughness and ease by bathing the mixer as described below.

Inspection & Cleaning

Taking the Mixer for a Bath

To clean the mixers produced for Agristo and others, including cereal bar makers, Ajax design their mixers with the ability to hold water when fitted with a closure plate ‘valve’ on the outlet. This enables the mixer to be filled with water and cleaning fluids, bathing the augers all whilst running the mixer augers back and forth to help loosen, dissolve and clean material quickly. The mixing action of the augers agitates any build-up, removing material from both augers and casing. Once the cleaning cycle is complete, the mixer casing’s gentle incline ensures all the water is drained via a valve fitted to the closure plate, allowing the cleaning water to be directed away from the normal production path.

Quick Release Augers

As a common adjunct, quick release augers allow screws to be easily removed. A recent mixer produced for a snack producer included quick release augers in addition to the ability to adjust its height or angle. These features enabled the screws to be disconnected for thorough cleaning as well as to change auger design to better suit the ingredients used in other recipes. While the potential to adjust the mixers height or angle was primarily included to meet the differing process needs of each product, it also helps to inspect and drain the mixer during cleaning.

Spray Bars

Some materials inevitably leave sticky residues which may be very awkward to remove. Materials such as fly ash or Air Pollution Control Residues (APCr) are often combined with a liquor to produce a well balanced and conditioned mix, though one which can be very difficult to remove with build-up potentially severely impacting processing performance, and, if left inside the mixer, even ‘set’ solid as to make restarting difficult.

Ajax recently worked with one of the UK’s leading waste resource management companies to enhance their processing of APCr. To allow APCr to be safely processed it must first be transformed into a non-hazardous state by treating it with an acidic liquor, a task the Ajax continuous mixer is ideal for. To condition the ash, Ajax designed a twin mixer with spray bars which enabled the liquor to be added where the mixing action is greatest to ensure the mix quickly achieves homogeneity and a balanced consistency neutralised for the next process.

To prevent treated APCr from setting and minimise operator exposure, a clean-in-place system for the mixer was also included which ran at the event of a production shift. Special swivelling spray bars with jet profiled nozzles were utilised to provide coverage of high pressure cleaning water along the length and breadth of the mixer targeting all of the areas whist the screws ran. For added access ease, counterbalanced covers were also included on this large machine to enable the inside of the mixer to be effortlessly and safely inspected by one operator and allow any maintenance required to be easily carried out.

Conclusion

To ensure a design that mixes well and offers clean, smooth operational capability it is essential to understand the materials and the process, so the needs of both can be addressed in the mixer’s design. The best way of doing this is through material testing to understand the materials cohesive and adhesive properties. The cleaning needs should meet not only regulatory compliance, in the case of say food hygiene, but also the needs for overall equipment effectiveness (OEE) for production goals to be met. These aspects may vary a lot depending on the actual mix and may mean it’s best to consider a customised mixer design for your particular process, as an off the shelf mixer is likely a poor compromise. As with almost all solids handling and processing operations, the ‘upfront’ extra effort and limited cost involved in gaining a better understanding of the material and process will often prove to be a very wise investment, saving many hours in cleaning or downtime and will offer a very quick payback in the life of the mixer.