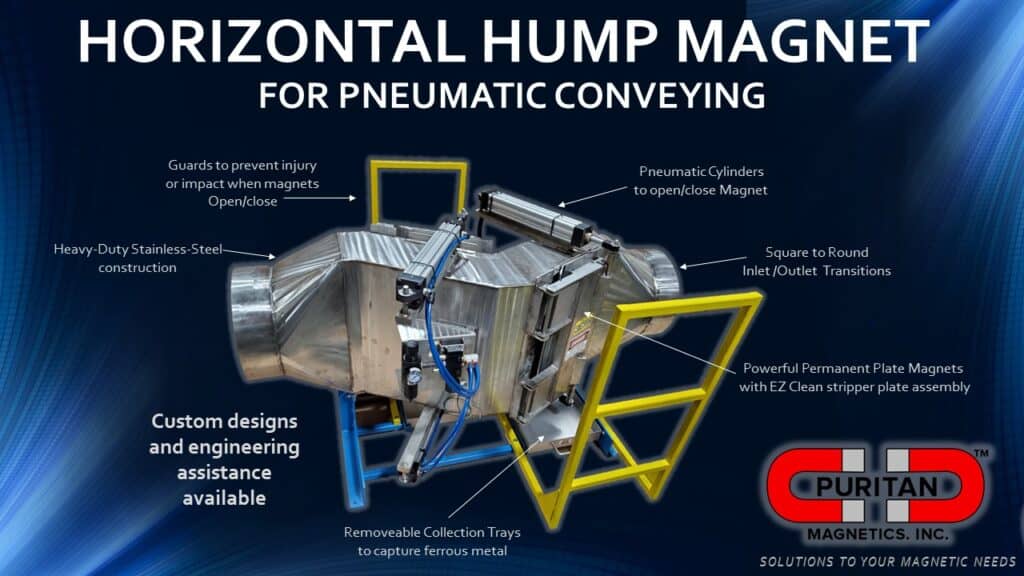

To combat this, powerful magnetic separators are strategically integrated into pneumatic conveying lines to capture and remove ferrous and weakly magnetic materials.

How Magnets Are Applied

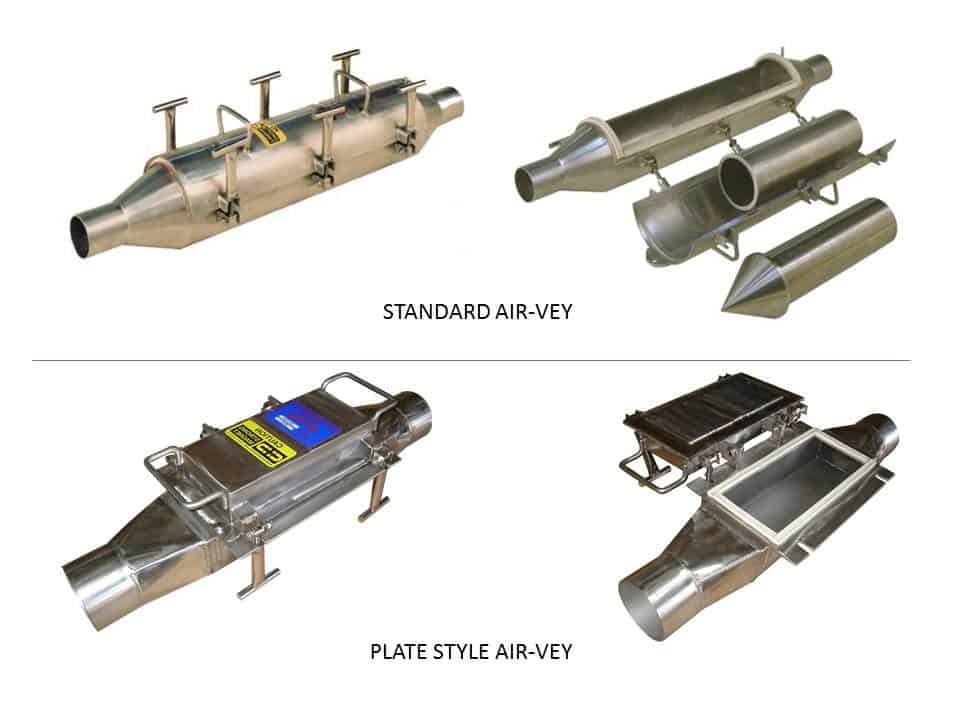

One common solution is the installation of In-Line Magnetic Separators, such as Air-Vey Magnets, which are designed specifically for pneumatic conveying systems. These units are engineered to fit directly into the conveying lines, where they efficiently remove tramp metal without interrupting product flow.

Key Features of In-Line Magnets in Pneumatic Conveying:

- Compact Design: In-line magnets, like Puritan’s Air-Vey models, are compact and easily integrated into existing pipelines.

- High-Strength Magnets: They utilize powerful Rare Earth or Ceramic magnets to capture even small or weakly magnetic particles.

- Minimal Flow Disruption: Their design allows for smooth material flow while maximizing metal separation efficiency.

- Quick-Clean Options: Many models offer quick-clean or self-cleaning features, reducing downtime during maintenance.

Air-Vey Magnet Example

Air-Vey magnets from Puritan Magnetics are a well-known example of magnetic separators used in pneumatic conveying. These units are often installed in conveying lines transporting plastic pellets, food ingredients, or powders. By removing ferrous contaminants, they help:

- Protect Downstream Equipment: Prevent damage to grinders, extruders, or packaging machinery.

- Maintain Product Quality: Ensure that finished goods are free from metal particles.

- Comply with Industry Standards: Support HACCP and other safety and quality regulations.

Conclusion

Magnets play a vital role in safeguarding both products and equipment in pneumatic conveying systems. With solutions like Puritan Magnetics’ Air-Vey units, industries can achieve higher levels of product purity, reduce equipment wear, and maintain a safe, efficient operation.