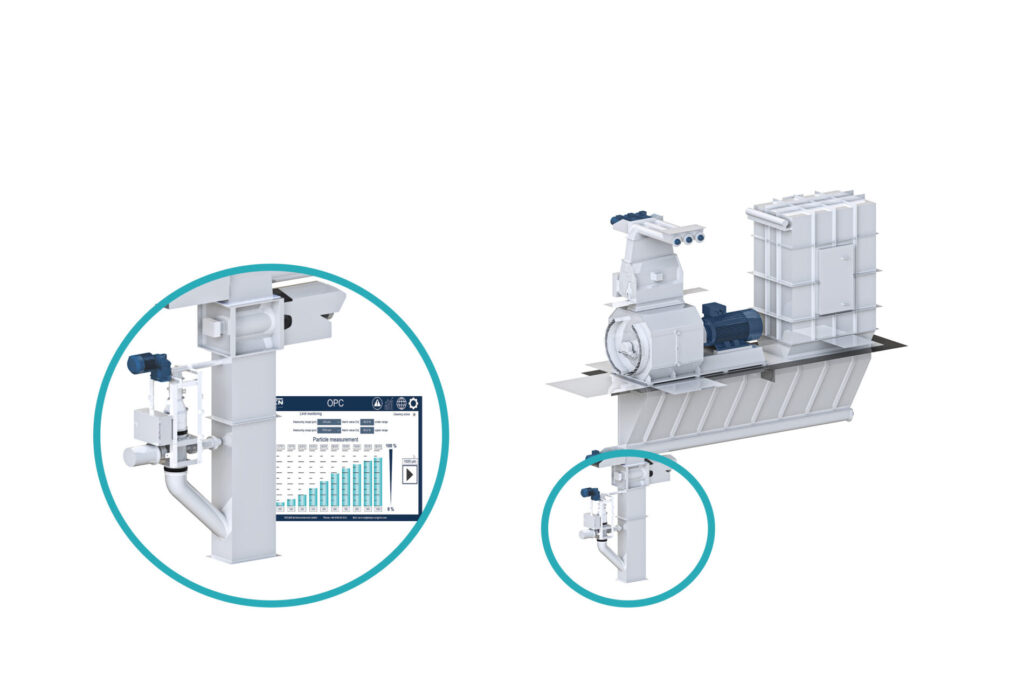

Continuous Monitoring at the Source

The OPC operates by extracting regular samples from the ground product stream. Utilizing a camera system, it analyzes these samples, accurately determining particle size distributions in real time.

Constructed entirely from stainless steel, the OPC ensures long-term durability and hygienic operation even in the most demanding industrial environments.

Effective Grinding Process

Real-time particle size measurement delivers comprehensive control over the grinding process:

- Early Detection of Equipment Issues: The OPC quickly identifies screen breakages or damages and wear on mill beaters and screens, minimizing the risk of unnoticed faults that could impact product quality.

- Customizable Alarms: The system allows for two individually programmable alarm thresholds. These can trigger if the proportion of fine or coarse particles drifts outside of target ranges, empowering operators to take immediate corrective action.

- Instantaneous Feedback: With real-time analysis, operators can react instantaneously to deviations, preventing quality issues from progressing further down the production line.

Maximizing Plant Availability and Maintenance Efficiency

Beyond quality assurance, the OPC plays an essential role in optimizing plant uptime and maintenance:

- Optimized Maintenance Scheduling: By continuously tracking changes in particle size, the OPC helps identify early signs of screen or beater wear, enabling well-timed maintenance interventions.

- Predictive Maintenance Support: Early detection of wear trends supports predictive maintenance strategies, reducing unexpected downtime and extending equipment life.

Flexible Integration and Broad Application

The OPC’s versatility ensures suitability across a wide spectrum of processes and materials:

- Universal Bulk Material Compatibility: Designed for free-flowing bulk goods, the system features a purge air connection for self-cleaning, which is particularly useful for greasy or sticky materials.

- Sample Management Options: Analysed samples can be returned to the product stream or discharge for traceability.

- Possible Seamless Product Changeovers: No recalibration is required when switching between different products or formulations.

Simple System Integration

Designed for user-friendly installation, the OPC can be retrofitted into existing systems or integrated into new projects. Full operability is available through an intuitive web interface, and the unit can be linked into broader process control systems for automated oversight.