Green cement tackles this issue by incorporating Supplementary Cementitious Materials (SCMs), such as activated clays, fly ash, and slag, which replace part of the conventional clinker—the primary source of emissions in cement. Activated clays are especially promising: they are abundant, locally available, and, when properly processed, can significantly reduce the carbon footprint of cement production.

Why Activated Clay?

Activated clays offer several environmental and practical benefits. By using local clay resources as SCMs, the need for clinker is reduced, which not only cuts emissions but also makes use of materials that are readily available around the world. Properly activated clays can serve as highly reactive components in cement blends, enabling greener and more sustainable building materials.

A New Way to Activate Clay: Mechanochemistry

Traditionally, activating clay requires high-temperature calcination—a process that consumes a lot of energy and is only suitable for certain types of clay, like kaolinite. A new approach, mechanochemical activation, uses mechanical energy (via ball milling) instead of heat to alter the clay’s crystal structure and enhance its reactivity. This method can be applied to a range of clay minerals (kaolinite, smectite, illite), offering:

- Significant CO₂ savings

- Lower energy consumption

- Precise control over material reactivity

- The ability to use local clays without extensive preprocessing

At the University of Bath, researchers are pioneering these innovative activation methods, moving the industry closer to sustainable cement technologies without the need for thermal processes.

How Ball Milling Works for Clay Activation

Ball mills, such as those in Retsch’s portfolio, are central to mechanochemical clay activation. By applying targeted mechanical energy, they transform various clays into highly reactive materials for green cement—without any need for high-temperature firing. Retsch’s ball mills stand out by offering:

- High energy input for efficient activation

- Multiple jar materials and sizes

- Precise control over grinding parameters

- Easy handling and scalability, from laboratory to small-scale pilot plants

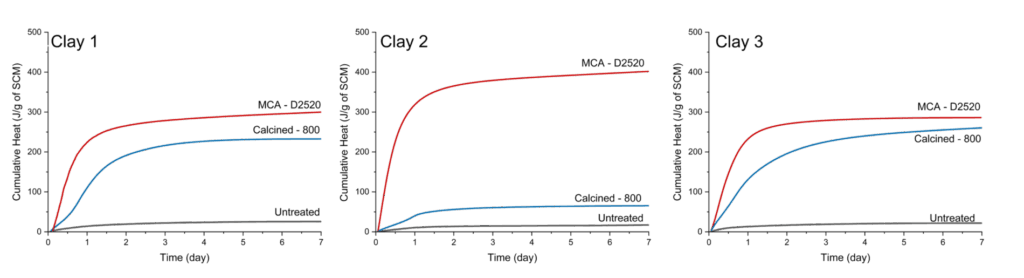

For example, the PM 100 planetary ball mill is ideal for activating different types of clay. Research shows that clays treated by this method become finer, structurally altered, and more chemically reactive than those activated by traditional calcination at 800 °C, especially clays with higher mica content[1], see figure 3.

Figure 2:

Sample processed in the Planetary Ball Mill PM 100

Speed: 500 rpm, Grinding Jar: 500 ml, Stainless Steel

Grinding Balls: 12 × 20 mm, Stainless Steel, Ball-Powder-Ratio: 25:1

The jar filling can be seen on the right picture (source: Department of Architecture & Civil Engineering, Centre for Climate Adaptation & Environment Research, University of Bath).

Figure 3: MCA-treated clays consistently outperform clay calcinated at 800 °C, indicating higher pozzolanic activity, especially in clay 2 with highest mica amounts.

The Planetary Ball Mill PM 100

The PM 100 is a versatile benchtop planetary ball mill designed for high-performance grinding, mixing, and homogenization. It features a single grinding station with powerful centrifugal forces, achieving particle sizes down to the nanometer range. With user-friendly operation, robust safety features, and advanced options like programmable standard operation procedures and real-time monitoring, the PM 100 is perfectly suited for mechanochemical research and routine sample preparation.

Temperature and pressure monitoring with GrindControl

A central aspect of process stability in mechanochemical clay activation is temperature control. The simultaneous recording of the pressure development provides additional information about chemical processes taking place. Retsch’s GrindControl system enables continuous measurement and documentation of the temperature and pressure inside the grinding jar. The GrindControl consists of a jar-lid with integrated sensors and data transmitting technology and is available for all jars from 50 – 500 ml size. Thanks to the modular lid insert, the system can be flexibly adapted to different jar materials, see figure 5.

The GrindControl measurement of the clay activation process shows that both temperature and pressure in the jar increase significantly during mechanochemical activation (see Figure 6). After 20 minutes, temperatures of up to 55 °C for all three clay types was observed. The pressures increase during the activation process was to 300 and 500 mbar for the first two clays a general indication of gas release, possibly due to the decomposition of carbonates. For the third one, a much higher increase to 1700 mbar was reached – corresponding to calcite /dolomite content shown in figure 1. Monitoring these parameters is essential to prevent overheating and to precisely analyze and control the reactivity of the mechanochemical process.

Conclusion: Mechanochemical Activation Paves the Way for Green Cement

Mechanochemical activation with Retsch ball mills offers a flexible, energy-efficient solution for producing sustainable cement. This process can be integrated into existing grinding operations, opening new possibilities for reducing emissions and utilizing local resources. With comprehensive equipment and accessories like the PM 100 or PM 300, and GrindControl system, Retsch supports both research and practical implementation of these advanced technologies – helping to build a greener future for the construction industry.

[1] Tole, I., Delogu, F., Qoku, E., Habermehl-Cwirzen, K., & Cwirzen, A. (2022). Enhancement of the pozzolanic activity of natural clays by mechanochemical activation. Construction and Building Materials, 352, 128739