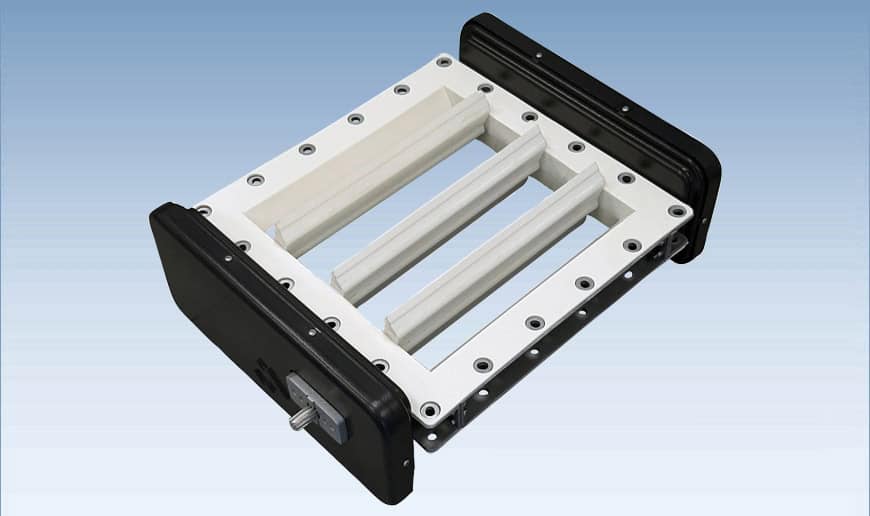

By minimising residue between the valve and the downstream equipment, the VPM Valve enhances hygiene, process efficiency and repeatability. It can be installed beneath hoppers, silos and big-bag dischargers, at inlet or outlet points of screw conveyors, or above belt conveyors.

How it works

The die-cast aluminium body houses three polymer-coated blades—one driving and two driven—together with an integral SINT® Engineering Polymer gasket that ensures tight material containment without the need for additional flange gaskets. Protective covers on both sides safeguard the mechanism and drive unit.

The profile and geometry of the blades enable controlled openings and smooth discharge, even with hygroscopic or poorly flowing materials. A vibrator kit for the blade shaft is available to further improve material flow.

Why the VPM Valve stands out

- Reduced residue: fewer build-ups and quick material changeovers.

- Superior sealing: the integral SINT® Engineering Polymer gasket reduces potential contaminations.

- Seamless integration: WAM® and CEMA compatibility allows quick installation in existing layouts.

- Versatility with “difficult” materials: blades and optional vibrators facilitate flow when handling crust-forming or hygroscopic products.

- Simplified maintenance: modular, replaceable components and easy access.

Fields of application

Feed and food, chemicals, plastics, drymix/building materials, detergents/cosmetics, glass and flour – wherever reliable interception and contamination prevention are required.

Versions and compliance

- Standard & Food Grade: available in compliance with Regulation (EC) 1935/2004 for processes with stringent hygiene requirements.

- Sizes: 300 mm (12”) and 400 mm (16”), square section.

- Actuators: manual, electropneumatic or electromechanical (supplied as standard without actuator).

Configurations & Options

- High-resistance SINT® Engineering Polymer-coated blades with replaceable integral seal (standard or food-grade).

- Vibrator kit on the blade shaft for poorly flowing materials.

- Flange options: WAM® and CEMA flanges.

Would you like to check compatibility with your layout or select actuators and flanges?

The WAMGROUP® team provides full support for product selection and integration, including data sheets, 2D/3D drawings and application advice.