Rotolok Limited are well known across the globe for their extensive range of Rotary Valves and offer a range of solutions for the processing of pharmaceuticals, supplements and other products where hygiene is of the utmost priority.

Our range of Kleanlok Valves developed and refined over many years offer a solution to meet the highest level of cleanliness required in the pharmaceutical industry.

When a long-standing customer came to us asking for a valve to meet their unique requirements Rotolok were up to the task.

The customer was looking to replace a competitor’s valve that was old and difficult to clean which meant excessive amounts of downtime when cleaning and maintenance were required.

The valve was required to process up to 90,000 completed medicinal capsules per hour whilst incorporating features to enable quick access for cleaning and full valve removal to aid access to adjacent systems.

The valve also needed to allow for full cleaning in place (CIP).

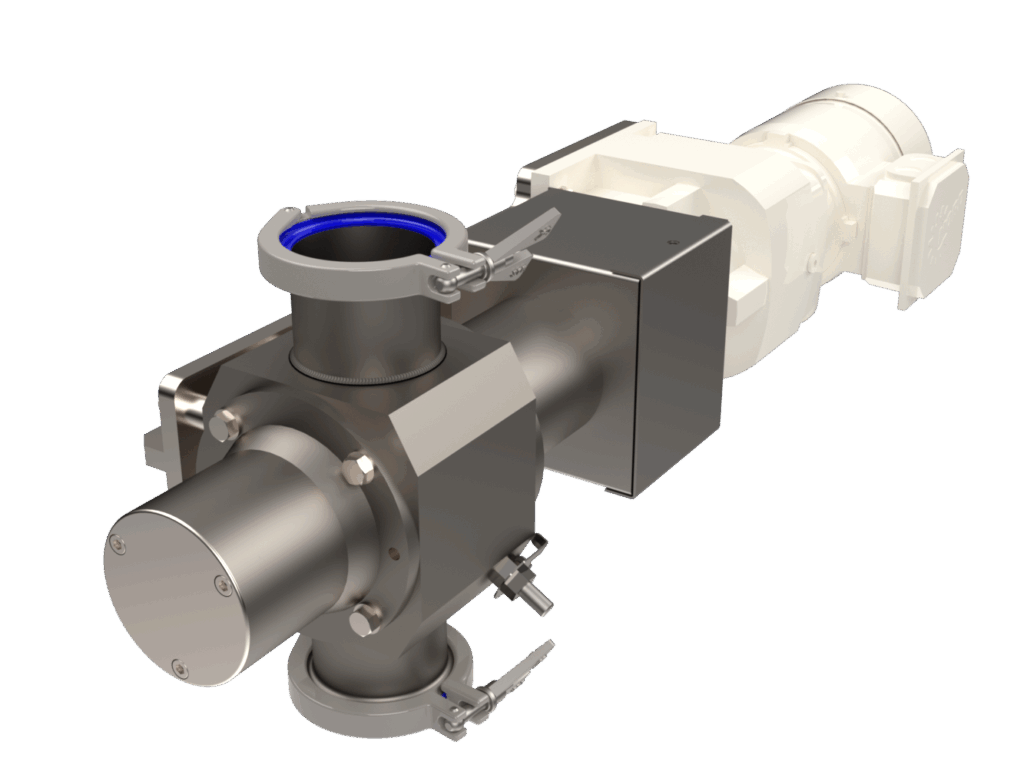

Our solution was a 75mm Kleanlok Valve with Quick Release rotor and tri-clamp connections at the inlet and outlet.

The Quick Release system enables the rotor and non-drive end cover to be quickly and easily withdrawn from the main valve body to allow for cleaning of the rotor assembly and access to clean the valve internals.

The tri-clamp connections integrated seamlessly with the valve body and enable the complete valve to be released from the system via two levers.

The Kleanlok range feature as standard cast 316 stainless steel body and end covers which are fully machined externally to provide clean lines and meet CIP requirements.

The valve internals are polished to ensure cleanliness and to aid in cleaning.

The rotors have machined scalloped pockets to ensure efficient product discharge and help prevent build up when handling products that have compacting characteristics.

The result was a hygienic valve that meets the rigorous demands and standards expected of the pharmaceutical industry with unique features to offer the customer exactly what they need.

Kevin Steele, Rotolok Sales Manager stated’ The finished valve met the clients brief in a unit that will provide faultless service for many years to come whilst providing reductions in downtime and cleaning costs to the customer.

Rotolok are proud to continue our long-standing support for this critically important sector in the British economy.’