How can you be sure that the correct amount is being moved at the right time? This is where accurate mass flow measurement becomes crucial. Choosing and designing a suitable measuring system plays a vital role. Otherwise, inaccurate measurement results can lead to misinterpretation, incorrect operation, suboptimal system utilization, or poor product quality.

In this article, Hense Wägetechnik provides an overview of which measuring systems are typically used in combination with the most common conveying systems.

Types of conveying systems: The backbone of bulk material transport

Bulk materials are transported using a variety of systems, each suited to specific types of materials and operational requirements. Below is an overview of commonly used conveying technologies, along with a matrix showing which measurement systems are typically applied in each type of conveyor system.

Belt conveyors

Belt conveyors consist of an endless belt that runs over pulleys. They’re widely used for transporting bulk materials over long distances and varying elevations.

Free-falling material (by force of gravity) on chutes, in pipes and channels

In pipes and channels, whether inclined or vertical, and on chutes, materials flow solely due to the force of gravity. This type of transport requires no energy, provided that a sufficient height difference and angle of inclination are available.

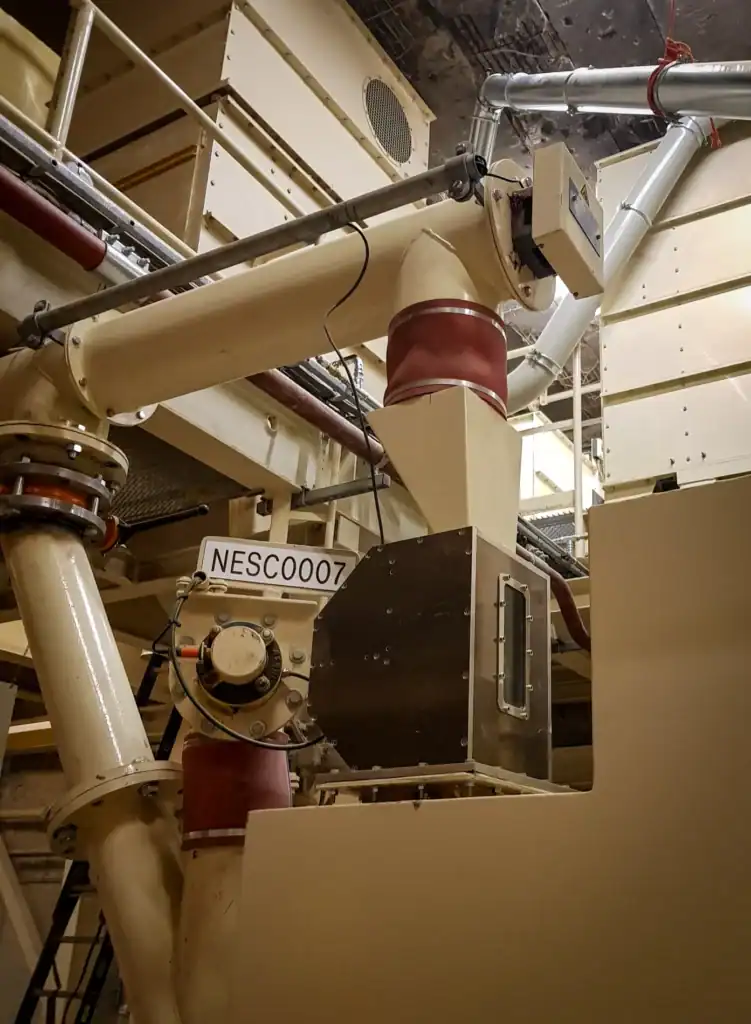

Rotary valves

Rotary valves (also known as rotary feeders or airlocks) regulate the flow of material from hoppers and silos. They maintain differences in atmospheric pressure and prevent material loss. They ensure a uniform and controlled discharge.

Bucket elevators

Bucket elevators are conveyors designed to move bulk materials vertically. Buckets are continuously moved along a belt or chain. Like belt conveyors, these are endless conveyors. They are often used for sensitive products.

Vibratory and oscillating conveyors

Vibratory (or oscillating) conveyors move materials through a trough using induced vibration. Besides transporting bulk materials, they are also used for screening and classification.

Screw conveyors

Screw conveyors transport bulk and viscous materials using rotating helical screws.

They allow both horizontal and ascending transportation. Due to their closed design, these systems are dust-tight.

Pneumatic conveying systems

Pneumatic conveying systems use air pressure or vacuum to transport materials through pipelines and hoses. They are particularly suitable for conveying powders and granular materials over long distances or along complex routes. Depending on the material properties, systems for thin or dense phase conveying are possible.

Airslides (fluidized bed conveyors)

Airslides use a layer of air to fluidize and convey powdered and fine-grained materials. The material flows over porous fabric plates, supported by a cushion of air, allowing for gentle and efficient transport without the use of mechanical parts.

Overview matrix: Which measurement technology for which conveying technology

The importance of accurate mass flow measurement

In industries processing bulk materials, it is crucial to accurately measure the amount of material transported for process control, inventory management, and quality assurance. Conventional methods such as volumetric flow meters, volumetric dosing, manual sampling, or power consumption of drives are usually inaccurate and time-consuming.

This is where measuring systems for bulk materials come into play, allowing direct recording of mass flow and conveyed mass. These systems are designed for maximum precision and reliability. They provide real-time data on mass flow, enabling effective monitoring and control of material transport.

The matrix below provides a compact overview of the measuring systems commonly used in practice in or in combination with the conveying systems described in this article:

| Conveying system / principle | mainly used | also used | seldom used |

| Belt conveyors | + belt scales | + flow meters for free falling bulk materials + batch weighers (in front or after conveyor) | + optical or radar-based belt scales + load cells |

| Gravimetric – chutes and pipes | + flow meters for free falling bulk materials + batch weighers (in front or after conveyor) | + weigh feeders + microwave sensors | + weighing screw conveyors |

| Rotary valves | + flow meters for free falling bulk materials (in front or after conveyor) | + batch weighers + weigh feeders | + load cells |

| Bucket elevators | + flow meters for free falling bulk materials + batch weighers (in front or after conveyor) | + load cells | + weigh feeders |

| Vibrating conveyors | + flow meters for free falling bulk materials + batch weighers (in front or after conveyor) | + load cells | + weigh feeders |

| Screw conveyors | + flow meters for free falling bulk materials (in front or after conveyor) | + batch weighers | + weighing screw conveyors |

| Pneumatic (dilute phase) | + microwave sensors, + ultrasonic sensors | + flow meters for free falling bulk materials + batch weighers (in front or after conveyor) | + load cells |

| Airslides | + microwave sensors | + flow meters for free falling bulk materials + batch weighers (in front or after conveyor) | + weigh feeders |

Table: Matrix – conveying technologies and suitable measuring technologies

Overview of measuring systems for flow measurement of bulk solids

Inline flow meter for free-flowing bulk materials

Flow meter using centripetal force

Centripetal force scales are highly precise mass flow meters for free-flowing bulk materials, including granules, pellets, flakes, and powders. They continuously measure mass flow rate using centripetal force, which is proportional to the mass. The system is highly insensitive to changes in bulk density, particle size, and material elasticity. It can be used for a large variety of materials.

Impact scales

Impact scales provide a robust and straightforward method for measuring the mass flow rate in dust-tight conveying paths. The bulk material hits an inclined “impact plate” in the bulk flow meter. The impact force is proportional to the mass in the case of very uniform bulk solids only. It is a commonly used process measurement, but only rarely used for precise mass measurement.

Flow sensors based on microwave technology

These systems are non-contact flow meters for bulk solids, based on microwave technology, and are ideal for use in pneumatic conveying systems or with free-falling materials. The sensors are wear- and maintenance-free. They provide real-time data on flow rate and total mass. The flow rates in applications for this technology are often displayed qualitatively, ranging from 0% (no flow) to 100% (maximum capacity). The flow inside a pipe becomes visible.

Load cell systems for flow measurement

Load cells can be used to measure the flow rate of bulk solids (and liquids) by weighing a suitably sized vessel or other reservoir as a buffer. The mass flow and the absolute quantity can be measured with great precision from the increase or decrease in mass within the vessel over time.

Batch weighers

Batch scales use the above principle. A batch weigher measures the mass of bulk goods in defined quantities (batches) and is particularly suitable for discontinuous processes such as filling bags or cardboard boxes. The bulk material is weighed statically (non-dynamically) in batches in a vessel with a flap mechanism. This ensures high precision and repeatability.

Belt scales

Gravimetric belt scales measure mass flow and total quantity of bulk goods transported on conveyor belts. The combination of weight and speed measurement allows calculating mass flow (t/h) and quantity (t). Belt scales are suitable for both retrofitting and planned conveyor belts.

Optical belt scales

This type of belt scale uses laser or radar technology detecting the material profile on a conveyor belt. This system measures volume flow (m³/h) and total volume (m³). Particularly suitable for applications when gravimetric belt scales are not feasible, e.g. for lightweight bulk materials and mobile machines.

Weigh feeder

A weigh feeder combines the functions of a belt conveyor with an integrated weighing unit. It continuously measures mass flow of bulk materials. The conveyor belt is specifically designed for precise weighing and can be used for lower mass flows than a retrofit belt scale for existing belt conveyors.

Weighing screw conveyors

This special type of screw conveyor is a sophisticated measuring system; therefore, it is rarely used due to its low measuring accuracy and specialized requirements. Like belt scales, weighing screw conveyors combine weight and speed measurement to calculate the mass flow (t/h).

Summary: Flow measurement solutions for different conveying systems

When it comes to bulk material transportation and conveying, the precise measurement of the amount of material moved is not only helpful, but also essential. Precise mass flow measurement enables efficient processes, quality control, compliance with industry standards and increases the cost efficiency of operations.

Just as conveying systems are tailored to specific materials and applications, the same applies to measurement technologies used in and combined with conveying systems. The matrix presented in this article facilitates the initial selection of suitable measuring systems and those used in practice.

Selecting the right measuring system requires a deep understanding of the material properties, the conveying system and the operating conditions. Hense Wägetechnik advises its customers on the selection of the optimum solution and supplies the most appropriate measuring system.