Understanding how hygienic design principles apply to weighing equipment helps you select solutions that protect both your product and your process. From smooth, easy-to-clean surfaces to sealed components, each element plays a vital role in preventing contamination and maintaining product integrity throughout production.

Understanding hygienic design

Hygienic design makes equipment easy to clean and prevents contamination from the equipment itself and any trapped materials. Key features include:

- Smooth, mirror-polished, self-draining surfaces that simplify cleaning and avoid residue buildup.

- Washer designs with tight seals and secure connections to block contaminants.

- Sealed joints and fully protected load cells to prevent ingress of dirt and moisture.

- No exposed threads or metal-to-metal contact to eliminate hidden contamination sites and reduce the risk of microorganism buildup.

Material and surface quality also play a crucial role:

- Stainless steel (AISI 304 and 316) is highly recommended for corrosion resistance and non-shedding properties.

- Truly smooth surfaces to minimize microbial adhesion.

- Electrical enclosures with appropriate ingress protection (IP) ratings to resist solids and liquids.

Why hygienic design matters

Maintaining a hygienic production environment is vital not only for compliance but also for the success of your entire business. Hygienic design safeguards your production by:

- Promoting product safety, reducing contamination risks and costly recalls

- Maintaining regulatory compliance, avoiding fines and shutdowns.

- Protecting your brand reputation through consistent quality.

- Building consumer trust in a market demanding transparency.

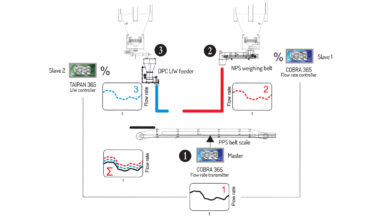

Tailored solutions for your production environment

Every production environment is unique, bringing its own set of hygiene challenges. METTLER TOLEDO offers tailored weighing solutions and services designed to meet these demands:

- Bench scales: METTLER TOLEDO hygienically designed bench scales are ideal for check-weighing and portioning areas, engineered for easy cleaning and contamination resistance.

- Floor scales: Frequently used in wet, harsh environments, METTLER TOLEDO floor scales are built to withstand heavy loads, rough handling, and exposure to waste materials.

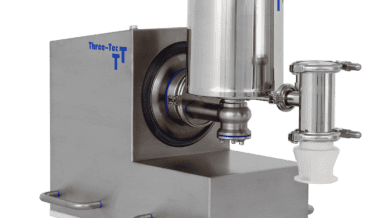

- Weigh modules: METTLER TOLEDO weigh modules deliver precise weighing results while withstanding regular wash-down procedures without compromising hygiene.

- Preventative maintenance: Routine maintenance of your scale not only helps it operate longer, but can maximize your efficiency and boost quality.

Investing in hygienic design not only allows you to meet compliance standards but also elevates safety, safeguards your brand reputation, and strengthens your business performance. METTLER TOLEDO is here to support you with solutions engineered for excellence and peace of mind.

For more detailed insights on hygienic weighing in regulated environments, download our free comprehensive guide and tools.