Dust and fine particles can create hazardous environments that need careful attention, particularly when weighing these materials.

Understanding explosive protection and process safety

In environments where explosive dust can be present, even small sparks or equipment failures can lead to serious incidents. It’s crucial to use equipment designed with these risks in mind. Weighing solutions for hazardous areas are built to operate safely without becoming a source of ignition. This means they must meet strict global standards such as ATEX or IECEx, which provide guidelines for equipment used in potentially explosive environments.

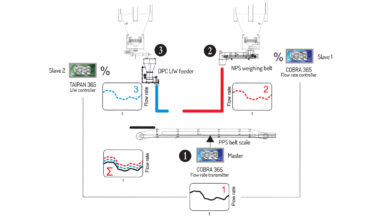

But safety isn’t just about compliance. Reliable weighing systems also help maintain product consistency, support smooth production workflows, and reduce the need for manual intervention in risky areas. Technology that allows remote monitoring of weighing processes lets operators keep a close eye on operations without entering hazardous zones.

Tailored solutions for your production environment

Every production environment has its own set of challenges—whether it’s the type of material being handled, the layout of the facility, or the regulatory framework in place. Solutions designed for hazardous areas take these factors into account by offering robust and flexible equipment options, and often feature flameproof housing, intrinsic safety designs, and enhanced sealing to prevent dust ingress and potential ignition sources.

METTLER TOLEDO offers a range of products engineered specifically for hazardous environments, such as explosion-proof floor scales which provide accurate weighing across various capacities, and are intrinsically safe and designed to support long-term safety, productivity, and quality in demanding conditions.

METTLER TOLEDO explosion-proof bench scales offer safe and precise weighing that helps streamline processes while the intrinsically safe weighing indicators are specifically designed to prevent the generation of heat or electrical energy that could ignite flammable substances. These indicators also feature explosion-proof enclosures, specialized wiring and connectors, and flame-retardant materials to enhance safety in hazardous environments.

Seamless integration of this weighing equipment into existing workflows and control systems plays a crucial role in minimizing downtime and enhancing overall process reliability. Additionally, comprehensive support services such as installation, calibration, training, and maintenance are also important to keep equipment performing well over time.

Navigating regulations and standards

Operating in hazardous areas means understanding and applying a range of international and local standards. Certifications like ATEX and IECEx provide a framework for classifying areas based on explosion risk and defining the technical requirements for equipment.

Partnering with METTLER TOLEDO means accessing products designed to meet global standards and experts who understand these regulations, making it easier to implement safe, compliant solutions tailored to your specific site conditions. Building on this partnership, leveraging expert guidance and specialized resources from METTLER TOLEDO enables teams to confidently navigate the complexities of hazardous area operations while enhancing safety and ensuring regulatory compliance.

Prioritizing safety, accuracy, and quality

Safety and operational efficiency must go hand in hand in hazardous environments. Reliable weighing solutions help control processes precisely while protecting people and maintaining product quality. By focusing on these priorities, METTLER TOLEDO can help you create safer, more efficient workflows that put people and product integrity first.