For free-flowing bulk materials, loss-in-weight (LIW) feeders have proven to be an effective and reliable solution. Their continuous, gravimetric control allows them to deliver material with high precision, even under fluctuating process conditions.

Why Use Vibrating feeders in LIW Systems?

In LIW feeding systems, the choice of discharge equipment is critical to ensuring performance. Vibrating feeders offer several advantages over conventional screws or belts:

- They do not exert shear or compressive forces, which makes them ideal for:

- Fragile products (e.g. food particles)

- Abrasive media (e.g. coarse powders or granules)

- Difficult-to-handle materials (e.g. fibers, glass fibers, or pharma powders)

- Their dead-zone-free design ensures hygienic operation and easy cleaning

- The electromagnetic vibration drive is nearly maintenance-free

Vibrating feeders are especially effective for homogeneous, high-throughput feeding, and offer gentle, uniform material flow. Unlike screw-based systems, they minimize material degradation and eliminate mechanical wear from contact with the product.

AViTEQ, as a manufacturer of both feeding and vibration technology, integrates vibrating feeders directly into its LIW systems. This in-house expertise allows for application-specific designs that can meet both performance and spatial requirements.

Standardized or Custom Solutions

AViTEQ offers its LIW systems in two main variants:

- Standard models: Built from proven modular components. These fulfill around 70% of typical customer requirements.

- Custom-designed systems: Tailored solutions for special applications involving limited installation space, unusual flow behavior, or high-accuracy requirements.

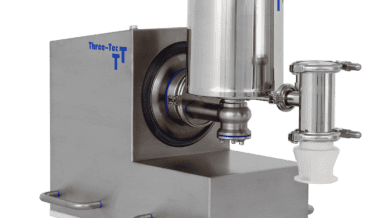

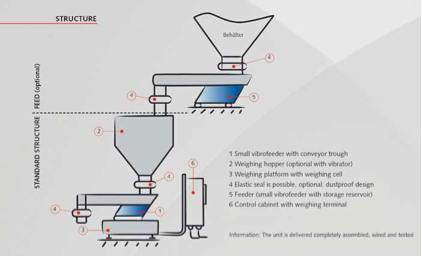

Both system types feature frame, weighing hopper, vibrating feeder, load cell, and a control unit, and can be fully pre-assembled, wired, and tested prior to delivery.

Operating Principle of a Loss-in-Weight System

The entire dosing unit—comprising the hopper, feeder, and drive—is mounted on a scale. The system continuously monitors the loss in weight as material is dispensed. Based on real-time feedback from a high-resolution load cell, the AViTEQ Vibtronic control unit adjusts the feed rate to maintain a precise setpoint.

A typical LIW cycle consists of three phases:

- Dosing(Gravimetric feeding)

Material is fed at a controlled rate. The actual flow is continuously weighed, allowing precise regulation based on target throughput. - Refill phase

Once a minimum fill level is reached, the hopper is refilled from above—often via a separate feeder or a pneumatic valve. During this time, the system temporarily switches to volumetric control. - Settling phase

A short stabilization period follows to eliminate vibrations and ensure weighing accuracy before resuming gravimetric dosing.

This control method makes LIW systems robust against material fluctuations—such as varying bulk densities or particle sizes—because flow control is based on weight, not volume.

Case Study:

Dosing Additives in Detergent Production

In a detergent manufacturing plant, sodium tripolyphosphate (STPP) is added as a water-softening agent during the mixing process. The challenge: feeding this abrasive, fine-particle salt at a rate of 50–1000 kg/h with a required accuracy of ±0.1%, both short- and long-term.

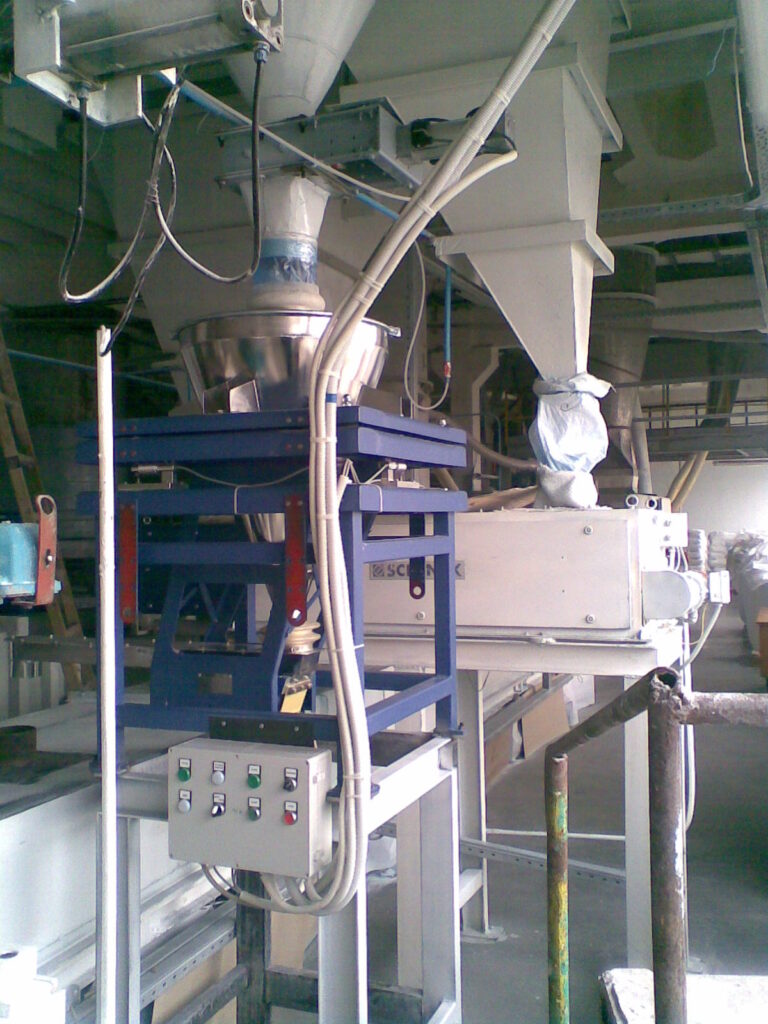

AViTEQ provided a customized LIW system including:

- Compact frame and hopper design

- Vibrating feeder adapted for STPP’s flow properties

- High-resolution load cell

- Pneumatic pusher (for clean separation from silo during refill)

- Integrated Vibtronic control system

The system was delivered fully assembled and tested, ensuring a seamless integration into the plant’s existing silo infrastructure. The pneumatic pusher, installed above the weighing hopper, acts as a refill valve, preventing uncontrolled material flow and maintaining consistent dosing behavior during phase transitions.

Conclusion

Loss-in-weight systems with vibrating feeders provide an accurate, gentle, and low-maintenance solution for continuous or batch feeding of free-flowing bulk solids. Especially for sensitive or abrasive materials, the vibrating feeder enables precise gravimetric control while minimizing wear and cleaning effort.

With its modular product range and in-house engineering, AViTEQ offers tailored solutions that combine mechanical reliability with high dosing performance—making them a strong partner for modern bulk solids processing.