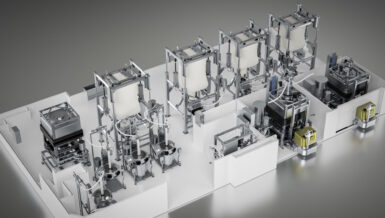

This was evident during a site visit to a large-scale mint candy manufacturing facility. The UWT US team, led by Branch Manager David Spratlin, took a close look at the manufacturing process. Discussions with the plant operators quickly revealed that handling ingredients ranging from fine powders to coarse granulates had caused significant challenges for the previously installed level measurement technology.

Before switching to UWT sensors, the mint candy manufacturer faced several recurring issues:

- Loss of calibration: Sensors lost their settings after every power outage or voltage dip and needed manual readjustment.

- Instability in the dust collection area: An originally installed tuning fork switch frequently failed whenever foreign objects such as cleaning cloths were drawn into the system and blocked the fork.

- Operational impact: Production stoppages, high maintenance needs, and increasing costs placed a heavy burden on the entire process.

The operators therefore sought a reliable solution that could provide consistent and precise measurements in both hygiene-sensitive areas and dust-laden environments.

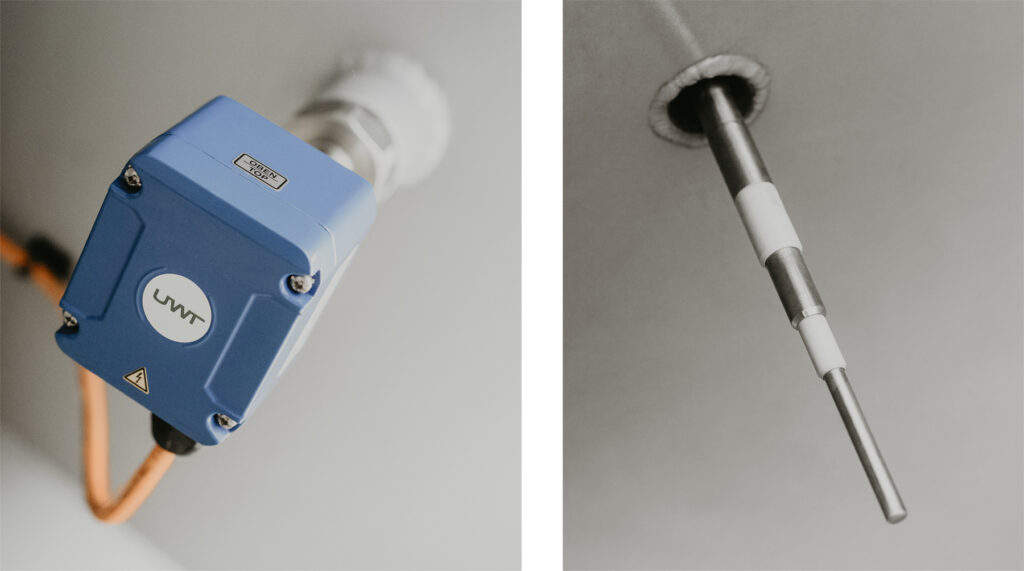

RFnivo® – Capacitive Level Limit Switch with Automatic Material Adjustment

By integrating the RFnivo® RF 3100 capacitive level limit switch from UWT, the plant was able to significantly increase process stability.

- Automatic Adjustment: The sensor automatically resets after power fluctuations, preventing downtime and production interruptions.

- Active Shield Technology: Ensures the sensor remains insensitive to material build-up on the probe – ideal for powder-based applications.

- Versatile Multitalent: Reliable, maintenance-free, and adaptable for nearly all bulk solid applications.

- Tri-Clamp Connection: Hygienic design for easy integration into existing systems, perfect for food production.

- Plug & Play: User-friendly level limit switch, ready for immediate use without complex setup.

Stability in the Dust Collection Area with the Rotonivo® Rotary Paddle Level Switch

Another critical area of the plant is the dust collection unit, where airborne particles and deposits pose particular challenges for sensor technology. Previously, a vibrating fork from another manufacturer was used. However, operators reported that foreign objects such as cleaning cloths occasionally entered the system and blocked the fork. This led to sensor failures and disrupted operations.

The switch to the Rotonivo® RN 6001 provided the required stability:

- Flexible Application Range: Reliable and durable across materials from fine powders to coarse bulk solids.

- Robust Rotary Principle: Designed so that the Rotonivo® paddle is unaffected by light foreign objects.

- Reliable Switching Function: Ensures continuous, troublefree operation even in dusty environments.

- Easy Integration: With flexible supply voltage options, the Rotonivo® can be operated directly with 120 V – matching the plant’s standard system voltage.

- Flexible Application Range: Reliable and durable across materials from fine powders to coarse bulk solids.

Voices from the Field: No More Downtime – Maximum Reliability

Since implementing UWT solutions, the production facility has not experienced a single downtime event related to level measurement.

“Since we started using UWT sensors, we can finally focus on what really matters: our production.”

“There are no unexpected failures anymore, no constant readjustments – instead we now benefit from stable processes and noticeably less effort in day-to-day operations. The automatic adjustment of the RF 3100 has made all the difference for us.”

Through close on-site collaboration with the customer and using customized sensor technology, UWT was able to deliver a solution that secures the production process long term – reliable, hygienic, and efficient.